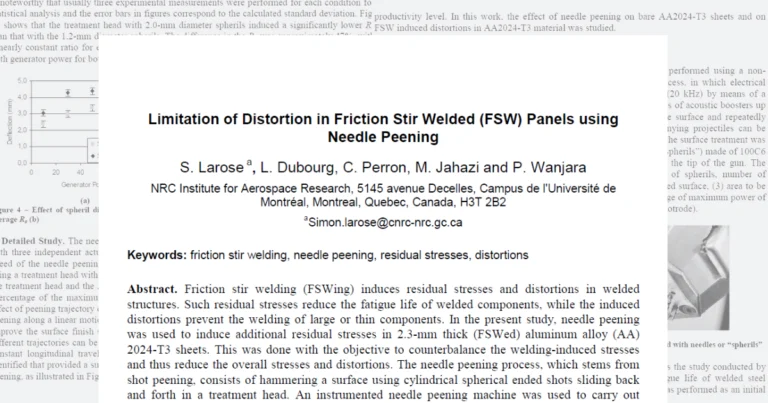

Limitation of Distortion in Friction Stir Welded (FSW) Panels using Needle Peening

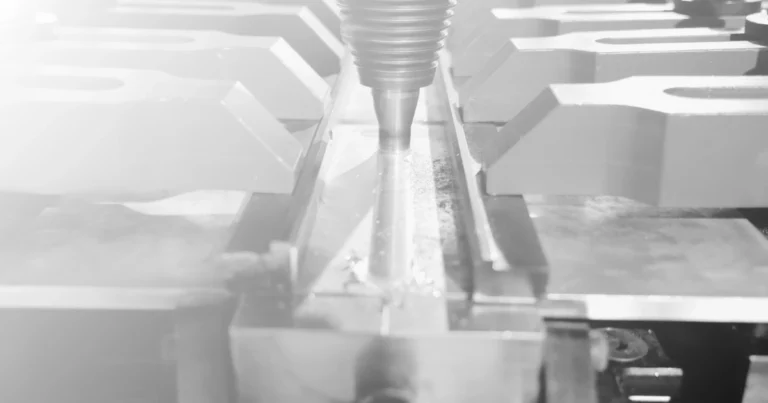

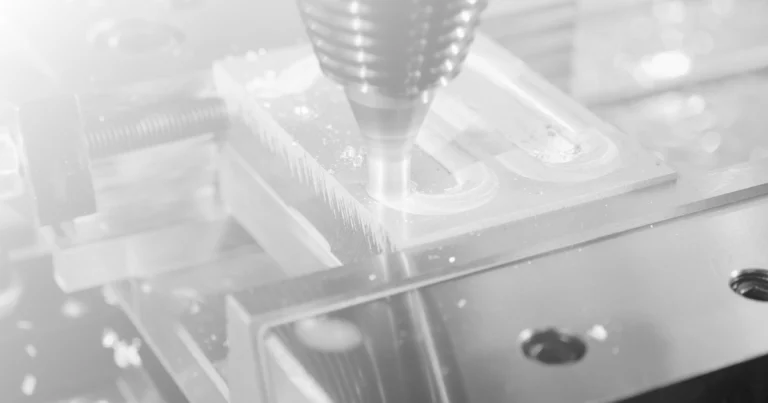

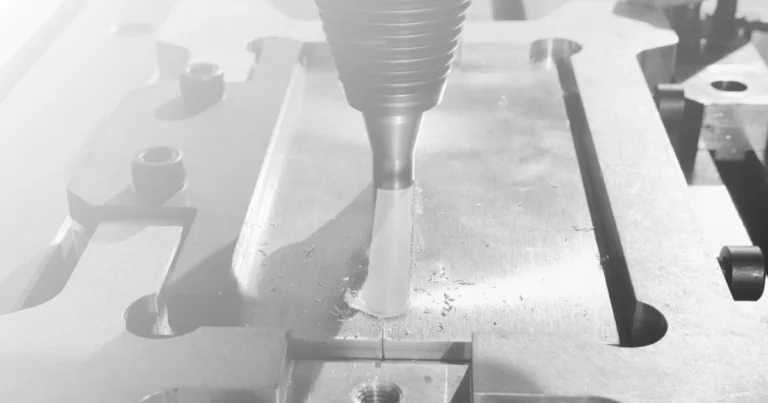

Limitation of distortion in FSW: Learn how needle peening reduces residual stresses and improves aluminum panel performance for aerospace. Download the full article here.