STIRWELD FSW TOOLS

FSW tools for

copper welding

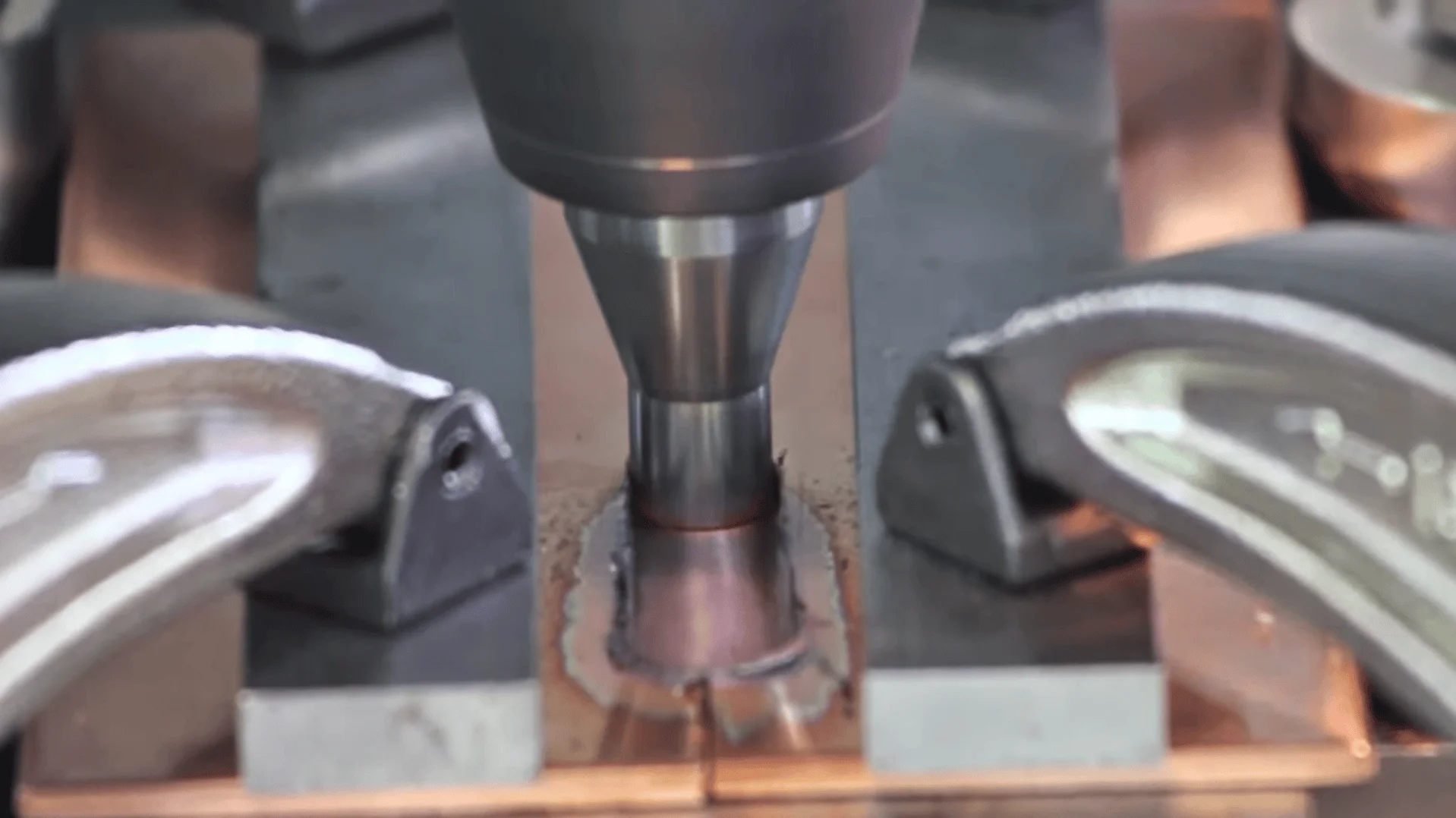

Tools crafted from high-temperature-resistant material to endure the heat during copper welding

Mastering Heat Resistance and Precision: Stirweld FSW Tools for Copper Welding

The challenge

Copper, being a highly conductive metal, presents unique challenges when undergoing the FSW process. As the welding progresses, the temperature can soar up to a staggering 900°C within the weld zone. Many standard FSW tools, not designed to handle such extreme conditions, tend to have their lifespan drastically reduced, leading to frequent replacements and increased operational costs.

The Stirweld solution

Recognizing this significant hurdle, Stirweld has innovated and introduced FSW tools specifically crafted from materials that can withstand high-temperature environments. By investing in these specially-designed tools, not only is the lifespan of the tool considerably extended, but the integrity and efficiency of the weld are also ensured. These tools have proven particularly beneficial for applications like efficient water heat sinks and bus bars, which play crucial roles in electrical systems. Through our dedication to excellence and innovation, we aim to provide solutions that enhance the overall welding process and final product quality.

FSW Tool Collection for Copper Welding

Copper, renowned for its superb conductivity and versatility, demands unique welding tools for optimal results. Within our collection, you’ll discover specially designed FSW tools tailored to meet the challenges and intricacies of copper welding, ensuring precision and efficiency at every step.

| WELD PENETRATION | WELDING TYPE | TOOL REFERENCE |

| 1 to 2 mm | Butt, lap, T-shape | F-CU-1-X |

| 2 to 3.5 mm | Butt, lap, T-shape | F-CU-2-X |

| 3 to 4.5 mm | Butt, lap, T-shape | F-CU-3-X |

To further enhance your welding experience, we present tools with a smart version capability: real-time temperature recording during the welding process. Whether you prefer the reliability of a fixed pin or the adaptability of a retractable one, our range caters to both preferences. While this collection showcases our standard offerings, remember that we’re not limited by it. Should you have a unique requirement, we’re on standby to develop specific tools in alignment with your specific applications, delivering a custom-built solution for your needs.

Maximize Your Copper Welding Efficiency!

Harness the power of precision with our specially crafted FSW tools. Whether it’s our standard collection or a custom-made solution, ensure every weld is of the highest quality.