STIRWELD FSW EQUIPMENT

FSW tools

Power and precision at a controlled cost for your FSW operations: experience FSW Stirweld tools.

Unmatched in Quality and Performance: What Sets the FSW Tools from Stirweld Apart?

Dive into the excellence of FSW tools from Stirweld. Affordable, top-quality and endorsed by industry giants like Ariane. Experience intuitive features such as the Whistle Notch system and unparalleled traceability. Plus, with our extensive stock of the most common tools, order today and they could be at your factory within 48 hours. Choose Stirweld for a seamless experience, prompt delivery and dedicated support.

Quality control

Each FSW tool undergoes rigorous quality checks, ensuring the highest standards in material selection, heat treatment and design geometry.

Low investment cost

Thanks to our large-scale production, the Stirweld FSW tools are competitively priced without compromising on quality.

Traceability

For assured quality and accountability, every FSW tool is equipped with a unique identifier for comprehensive traceability.

Ease of use

Experience seamless operations with Stirweld’s FSW tools, enhanced by the intuitive Whistle Notch attachment system.

Peak performance

Designed with precision, our FSW tools minimize defects, boost productivity and consistently prove their durability in wear bench tests.

Qualification

Stirweld conducts thorough pre-production validation to ensure each tool and procedure aligns perfectly with your specific application needs.

Key Components of FSW Tools: Understanding the Shoulder & Pin Dynamics

An FSW tool is primarily composed of two vital components:

Friction Stir Welding Tools: Explore Our Diverse and Specialized Range

Dive into our range of tools, meticulously crafted with cutting-edge Friction Stir Welding technology tailored for every material you need to weld. Every tool type we offer represents a harmonious fusion of innovation, precision and adaptability. Engineered to satisfy varied industrial needs, our selection ensures superior performance and unmatched versatility for all your welding applications.

FSW tools for aluminium welding

Efficient welding for all aluminum alloys: 1xxx, 2xxx, 3xxx, 5xxx, 6xxx and 7xxx series.

FSW tools for welding aluminium to steel

Weld over 800 meters of aluminium to steel.

FSW tools for welding casting aluminium

Achieve over 1,500 meters of cast aluminium welding.

FSW tools for copper welding

Tool in high temperature material to stand the temperature during copper welding.

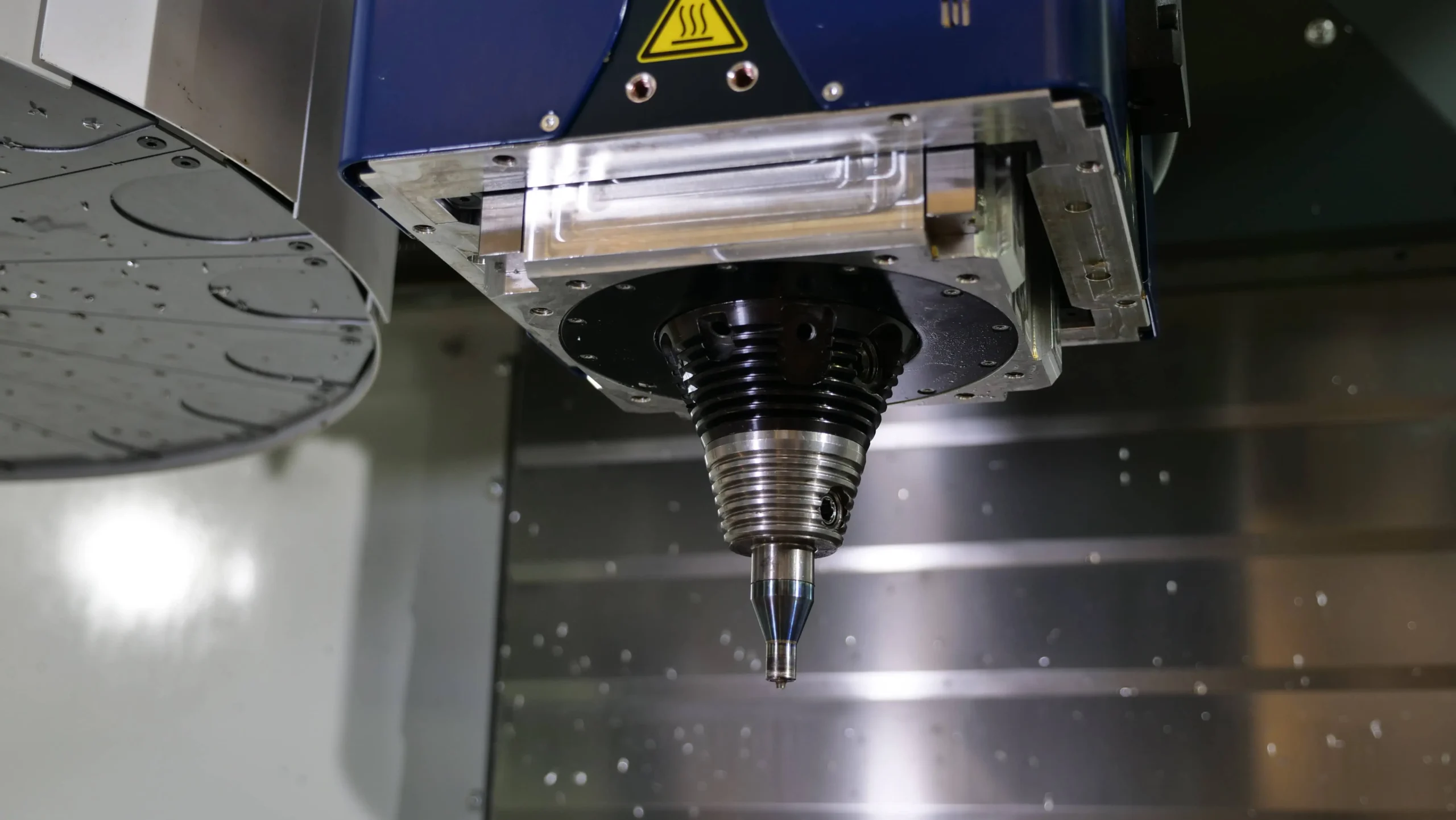

Friction Stir Welding Tools Holders:

Our Versatile Solution for FSW, Drilling and Milling

The reliability of our tool holders is ensured through stringent quality checks encompassing geometry, material and hardness, and they boast standardization with the Whistle Notch attachment system. Choose from two options: standard or smart versions.

Standard tool holder

We supply a range of standard tool holders, designed for both milling and drilling operations as well as Friction Stir Welding. Choose from fixed or retractable options.

Smart tool holder

We offer a smart tool holder designed to measure temperatures during welding, a crucial factor for ensuring the quality of your welds. Explore our advanced smart tool holder now.

Choosing the Right FSW Tool: Essential Criteria Breakdown

The art and science of Friction Stir Welding revolve significantly around the tool you employ. An appropriate FSW tool doesn’t just facilitate the welding process—it’s the backbone to achieving a weld of superior quality and durability. As you navigate through this welding journey, it’s paramount to take into account critical parameters like the distance to be welded, the depth of the weld, the unique geometry of the tool and the specific material you’re working with. These factors are not mere details; they fundamentally shape the welding outcome, determining factors like strength, finish and the overall integrity of the weld.

Just as a chef chooses their knife or an artist selects their brush, so too must an FSW professional carefully choose their tool. A meticulously selected tool not only ensures optimal welding results but also prolongs the lifetime of the tool and maximizes the efficiency of the operation, reinforcing the essential link between tool choice and welding quality.

For those eager to delve deeper into this topic, we have an article titled “How to choose my FSW tool for my application?” that provides a comprehensive guide.

Explore Our Complete FSW Tool Range

Dive into the details of each of our FSW tools and discover the perfect fit for your application. Our comprehensive catalogue showcases the diversity and quality of our range, ensuring you’re equipped with the best for your welding endeavors.

Frequently Asked Questions

Find quick answers to your questions with our FAQ. This section covers a range of common inquiries, providing you with immediate solutions and detailed information.

Yes, Stirweld offers the development of custom FSW tools to suit the specific needs of our customers. We also offer a wide range of standard FSW tools available in our catalog.

We study the customer’s request and help him to choose the right tool for his FSW project. We propose the FSW tool perfectly adapted to his equipment and applications.

The FSW tool pin is one of the components of our friction stir welding tools. It is located at the end of the tool in the extension of the shoulder. The length of the FSW tool pin depends on the thickness of the parts to be welded and the welding configuration.

The threaded pin ensures efficient mixing by penetrating the material and mixing it. This shearing effect provides an additional amount of heat that contributes to the plastic deformation of the material. Its sharp point ensures a better penetration of the tool’s pin into the workpiece and thus a more efficient FSW welding operation.

Stirweld offers a complete range of FSW tools according to the materials of your parts. The French space giant Ariane already trusts us for the purchase of its FSW tools. Download our catalog which lists our standardized FSW tools.

The average life of our tools is 2000 metres of weld in a typical FSW configuration.

The life of the FSW tool varies depending on 2 key factors: the correct use of the tool and its settings. The most common causes of wear are cyclic fatigue at the pin and abrasive wear due to frictional action.

Its life will also depend on the thickness of the parts and the materials welded: aluminium/aluminium, aluminium/copper, aluminium/steel…

While you await our response from the FSW technical support center, you may find helpful information in our detailed FAQ section. It offers a wealth of answers to common challenges and is continuously updated to include the latest insights and solutions.