STIRWELD FSW EQUIPMENT

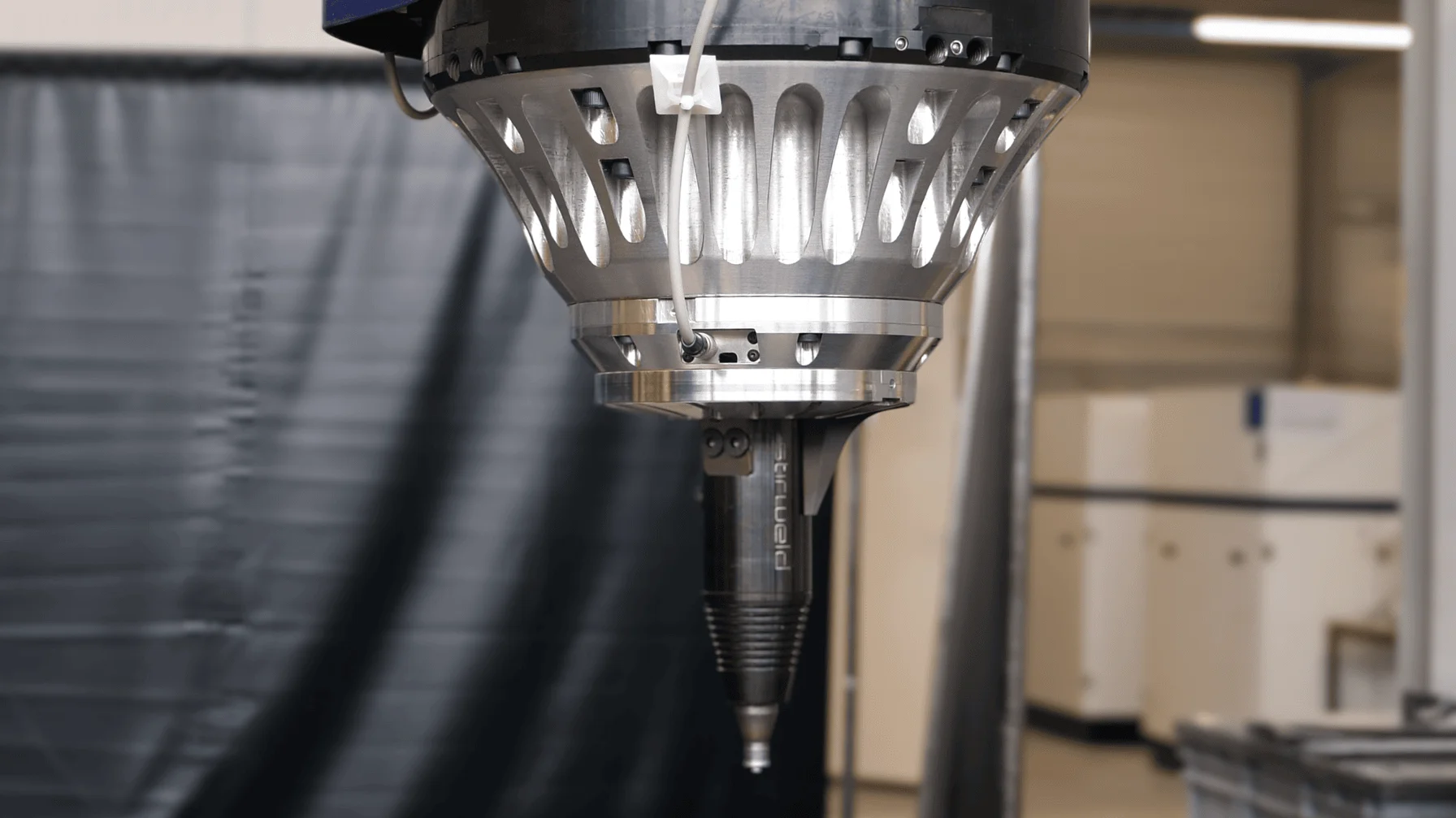

FSW spindle

for robot

Transform your robot into a cutting-edge friction stir welding powerhouse. Experience unparalleled precision, efficiency, and quality with our FSW spindle for robots.

Why Equip Your Payload Robot with the FSW Spindle?

No hydraulic power

The Stirweld FSW spindle for robots operates without hydraulic power, making it more cost-effective and maintenance-free, relying solely on electrical and pneumatic power.

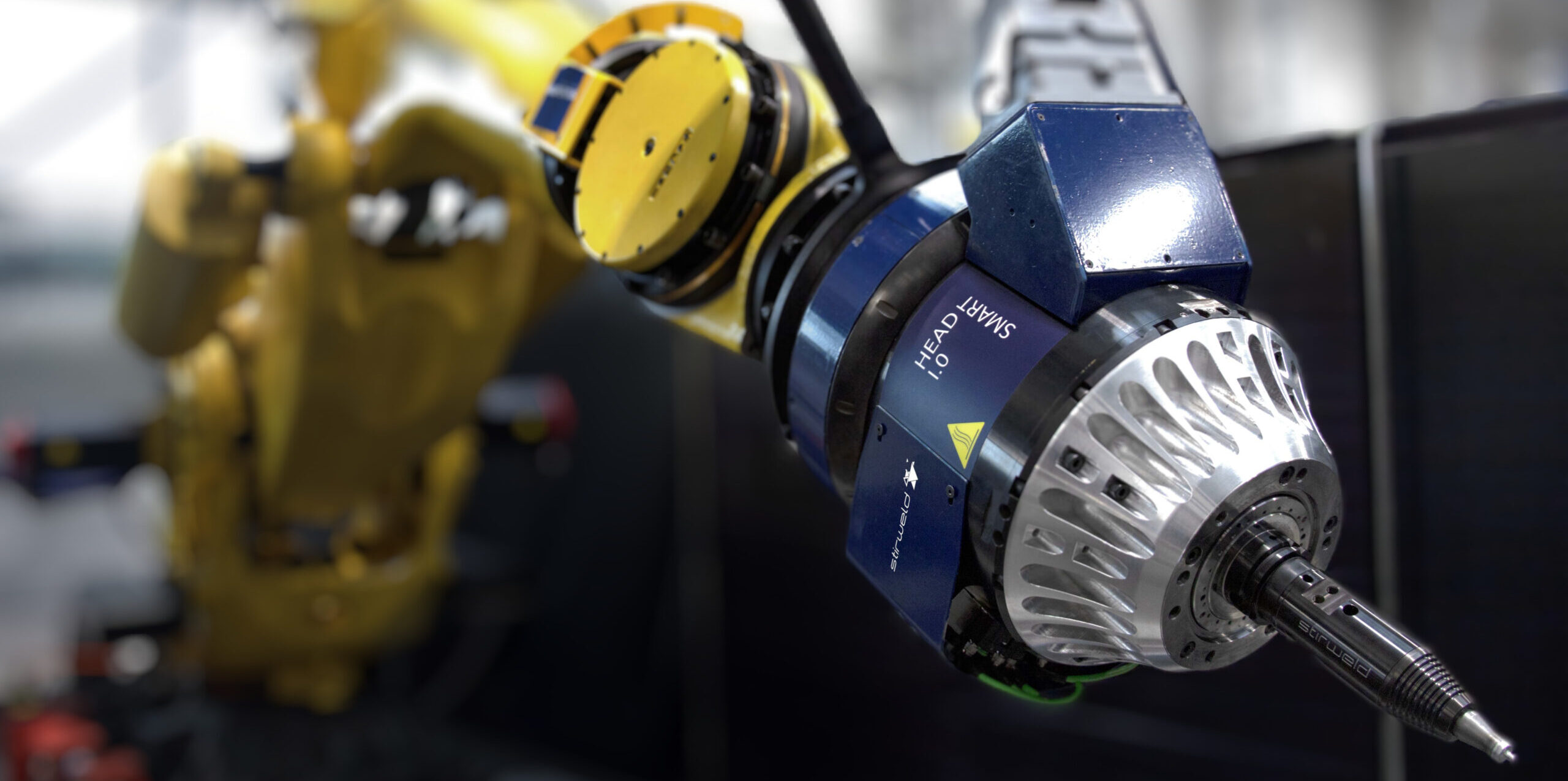

Adaptability

Designed for exceptional versatility, the Stirweld FSW spindle is suitable for all robot integrators and aligns seamlessly with every high payload robot model on the market.

Hybrid FSW spindle

Merge welding and milling tasks effortlessly at one station with the Stirweld hybrid FSW spindle, equipped with an innovative automatic tool changer.

Automatic tool change

With the Stirweld FSW spindle for robots, experience the convenience of automatic tool changing and hands-free management of FSW tool lifespan.

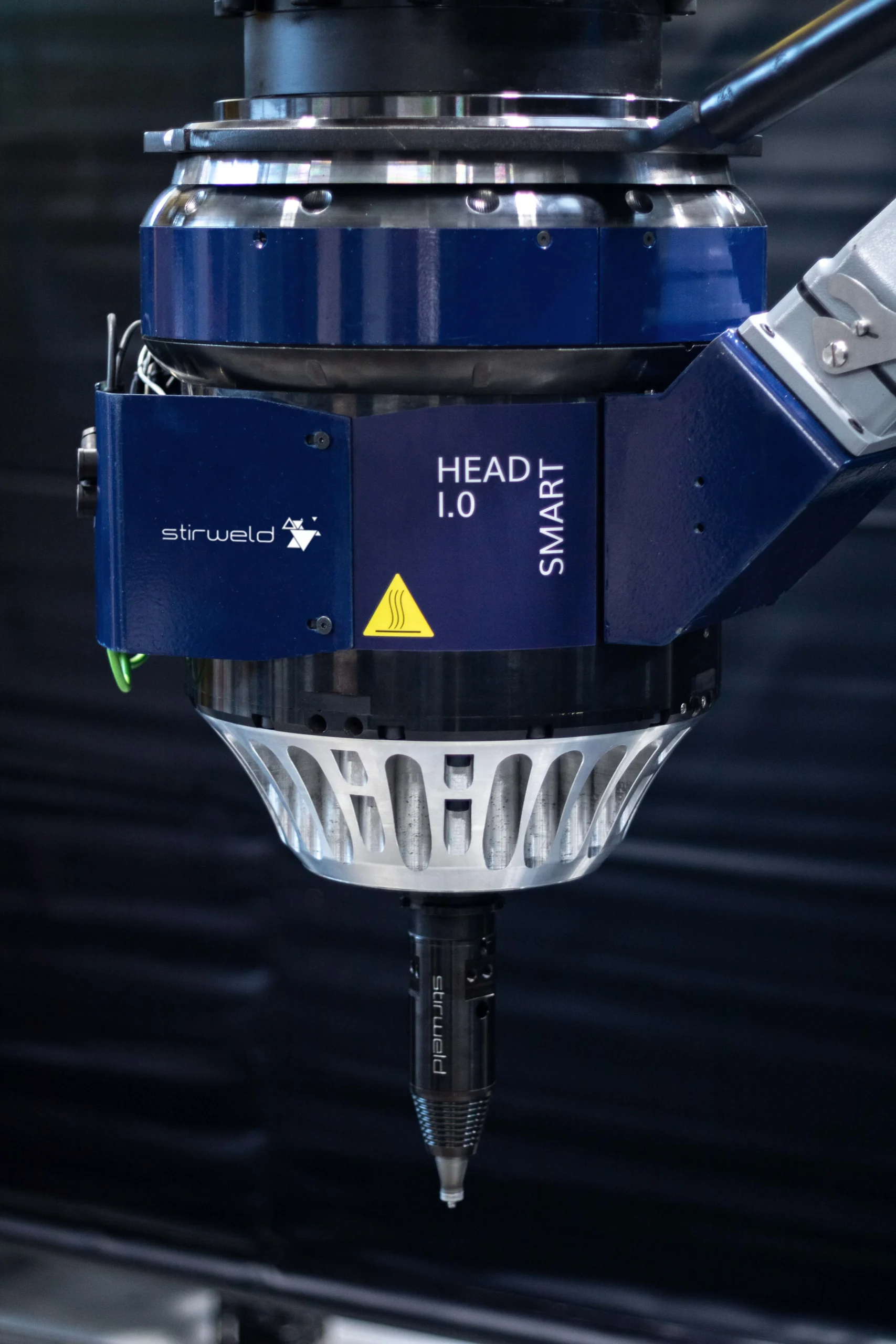

Unlocking Friction Stir Welding: Key Features of the Standard FSW Head

Rotational speed

The Stirweld FSW spindle reaches 9000 RPM with both clockwise and counterclockwise rotation, enhanced by RPM monitoring and FSW parameter optimization for optimal performance.

Welding speed

The Stirweld FSW spindle offers welding speeds of up to 4 m/min. With its FSW weld quality control, it has parameter optimization features for adjusting the welding speed.

Force control

The Stirweld FSW robot spindle handles up to 12 kN, offers forging force monitoring, and allows fine-tuning of forging force parameters for peak performance.

FSW torque

With the capability of 100 N.m at 3,000 RPM and 30 N.m at 9,000 RPM, our Stirweld FSW spindle prioritizes torque monitoring and fine-tuning to ensure optimal weld quality.

Automatic tool changer

Enhance operations with our HSK63-equipped tool changer. Perfect for FSW/milling. Features automatic FSW tool life management and safety protocols.

Cooling efficiency

Using water cooling, the spindle system cools the shaft, motor and housing, ensuring consistent FSW tool temperature. It also monitors water flow and temperature with a safety emergency stop.

Spindle temperature

For maximum safety, an immediate emergency stop is included. The spindle has triple thermal sensors for precise temperature monitoring and enhanced protection.

Warning pop-up

Warning system with two thresholds designed by FSW welders: vigilance and problem detection. The vigilance alert activates for deviations from the standard process, while problem detection responds to safety process breaches.

Spindle Activity Monitoring

Comprehensive logging of welding time, usage ratio and spindle activation.

FSW Spindle integrations

Our FSW spindle for industrial robots is designed for outstanding versatility, suitable for all robot integrators, and seamlessly compatible with every high payload robot model on the market. The Stirweld FSW spindle works with any heavy payload robot (minimum payload of 500 kg), including brands like KUKA, ABB, Fanuc and Yaskawa.

Technical Specifications of the FSW Spindle for Robot

Conceived by specialists in friction stir welding, our FSW spindle for robot elevates any high payload robot into a multifunctional powerhouse. This solution not only facilitates Friction Stir Welding but also transforms your robot into a dual-purpose instrument capable of both welding and machining.

| Rotational speed | Up to 8000 RPM for high welding and milling speed |

| Maximum payload | 12 kN |

| Cooling system | Full water cooling for high productivity |

| Monitoring | Full monitoring for 100% online quality control (according to EN 9100 standard) |

| Power | Full electrical ad pneumatic power (no hydraulic power) |

Human Machine Interface of FSW Spindle for Robot

This state-of-the-art Human Machine Interface (HMI) seamlessly integrates into the modern industrial landscape, offering a range of connected functionalities. With this system, users can effortlessly initiate manufacturing orders, manage tailored production recipes featuring precise welding parameters and generate vital data files. Additionally, operators have manual control over specific events, the ability to adjust the retractable pin length, access real-time system status reports and can view selectable value curves to ensure impeccable weld quality. Dive into the future of welding with our advanced interface, designed for today’s robotic applications.

“The functionalities are impressive and ahead of most available systems on the market. It is good to see that the spindle has all the sensors included to make it a smart system. Also, it is nice to see the « true tilt » measurement.”

Confidential

Senior project leader of worldwide technological center

Advanced Option of Our FSW Spindle for Robot

Designed for craftsmen and professionals striving for utmost accuracy, our FSW spindle embodies advanced features that set it apart in weld quality.

Explore the next generation of FSW with our advanced smart tool holder, a testament to Stirweld’s commitment to innovation and excellence in the realm of welding.

Smart tool holder

Smart tool holder measures weld temperatures for precise FSW quality & parameter optimization.

Dimensions of our FSW Spindle for Robot

| Size | Height of 576 mm (22.68 in) |

| Weight | 150 kg |

| Center of gravity relative to the robot flange | X = 0 mm Y = 0 mm Z = 200 mm |

| Spatial position of FSW forces relative to the robot flange | X = 0 mm Y = 0 mm Z = 520 mm |

Curious about the future of robotic welding? Dive deeper with our comprehensive article on Robotic Friction Stir Welding. Learn about this advanced industrial equipment, celebrated as the most efficient on the market. Understand the unique advantages of integrating friction stir welding with robotics, from assembling 3D joints for sizable parts to reaping the benefits of enhanced productivity with our FSW robot spindle. Discover the innovations and technical prowess of our hybrid FSW spindle for high payload robots. Delve into its technical details, the pioneering features it offers and the collaborative spirit behind this groundbreaking project.

Ready to Elevate Your Welding Game?

If our FSW spindle for robots piqued your interest, don’t hesitate! Reach out now for a personalized quote and embark on the journey to unparalleled welding precision.