Transform your CNC machine into a high-precision Friction Stir Welding Machine

Our FSW welding head enables 4 functions on your CNC machine to perform aluminum workpiece assembly through friction stir welding. This solid-state welding process ensures a high-quality weld seam that preserves the base alloy’s original properties.

Bridging the gap: From CNC machine to Friction Stir Welding with Stirweld

Standard CNC machines fail to create quality friction stir welds because of fourmain operational restrictions.

The lack of control

Poor control during welding operations leads to various defects in the finished welded piece. The welder faces difficulties in maintaining accurate control and pressure application when there is no suitable controller support.

The impossibility of cooling

It is impossible to cool the tool without simultaneously cooling the workpiece. The weld process requires accurate temperature management to avoid machine damage and extend its operational life.

The absence of control

The FSW process lacks built-in pressure control functionality for part contact force management which creates a fundamental requirement for producing strong reliable welds.

Possible damages to the CNC machine

The CNC machine faces the danger of structural damage from FSW process-generated forces and vibrations. Prolonged exposure to these effects can necessitate part polishing and leads to diminished mechanical system integrity.

Using a traditional CNC machine leads to FSW being an unrepeatable process. The technique proves useful for students with research or academic needs yet produces welds of insufficient quality for industrial applications that require fast and precise welding.

Nevertheless, the Stirweld FSW head head adds these four fundamental capabilities to any CNC machine so you can create high-quality aluminum welds by friction stir welding.

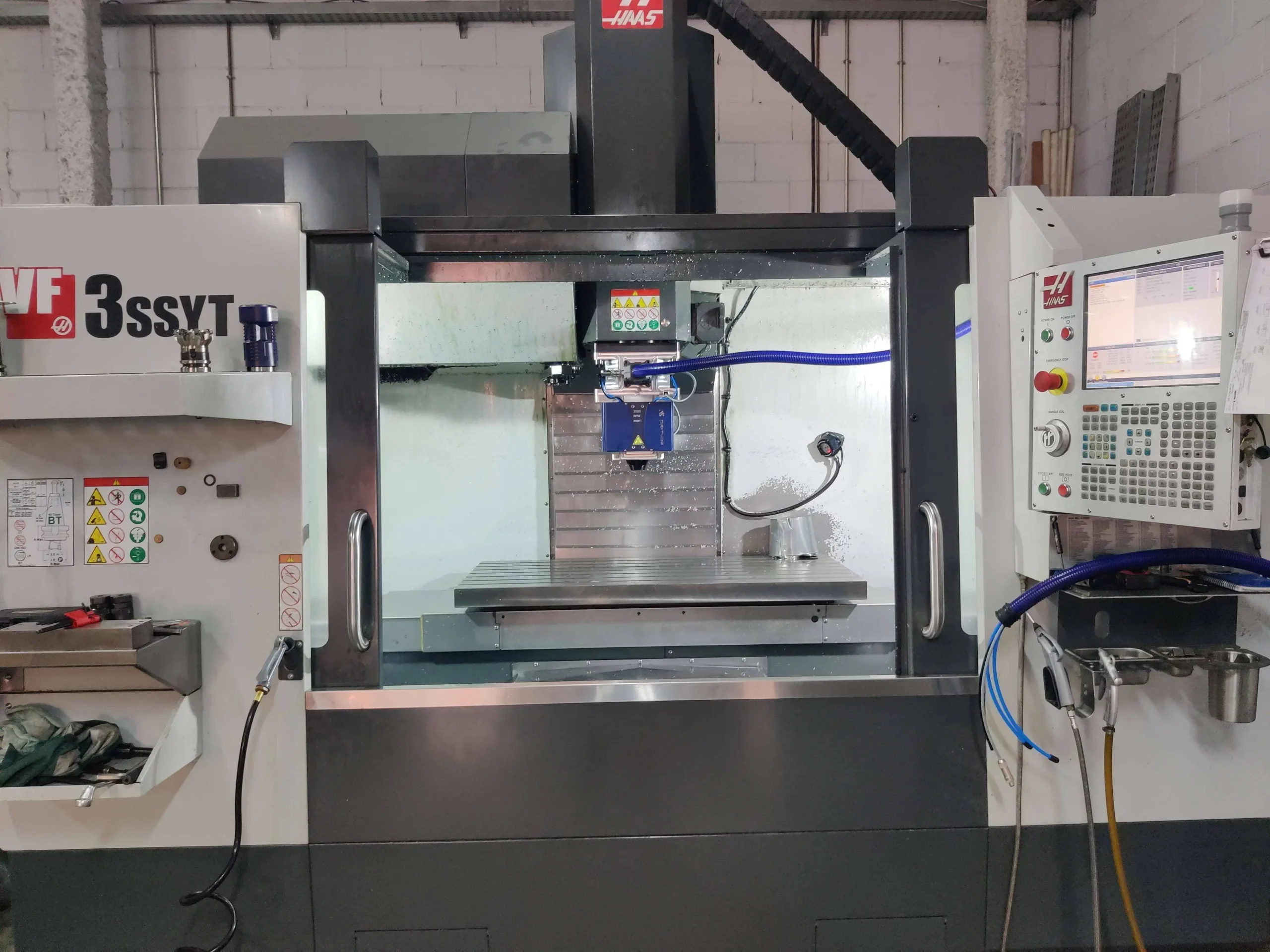

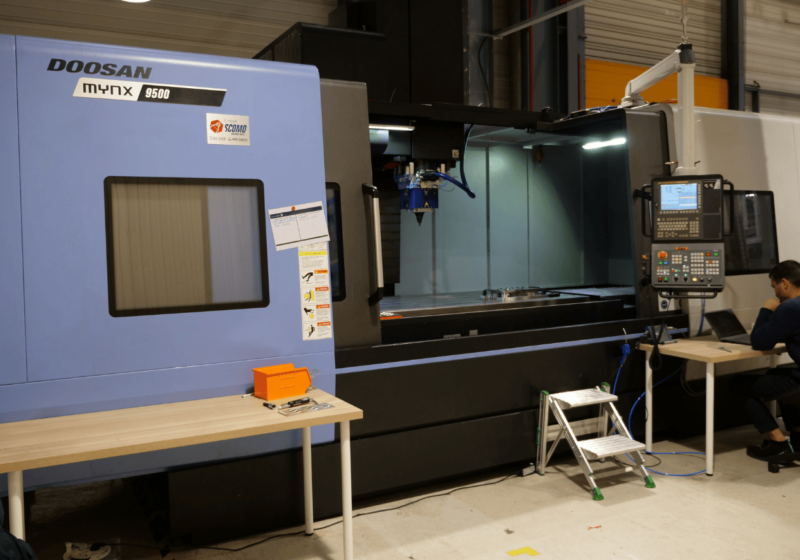

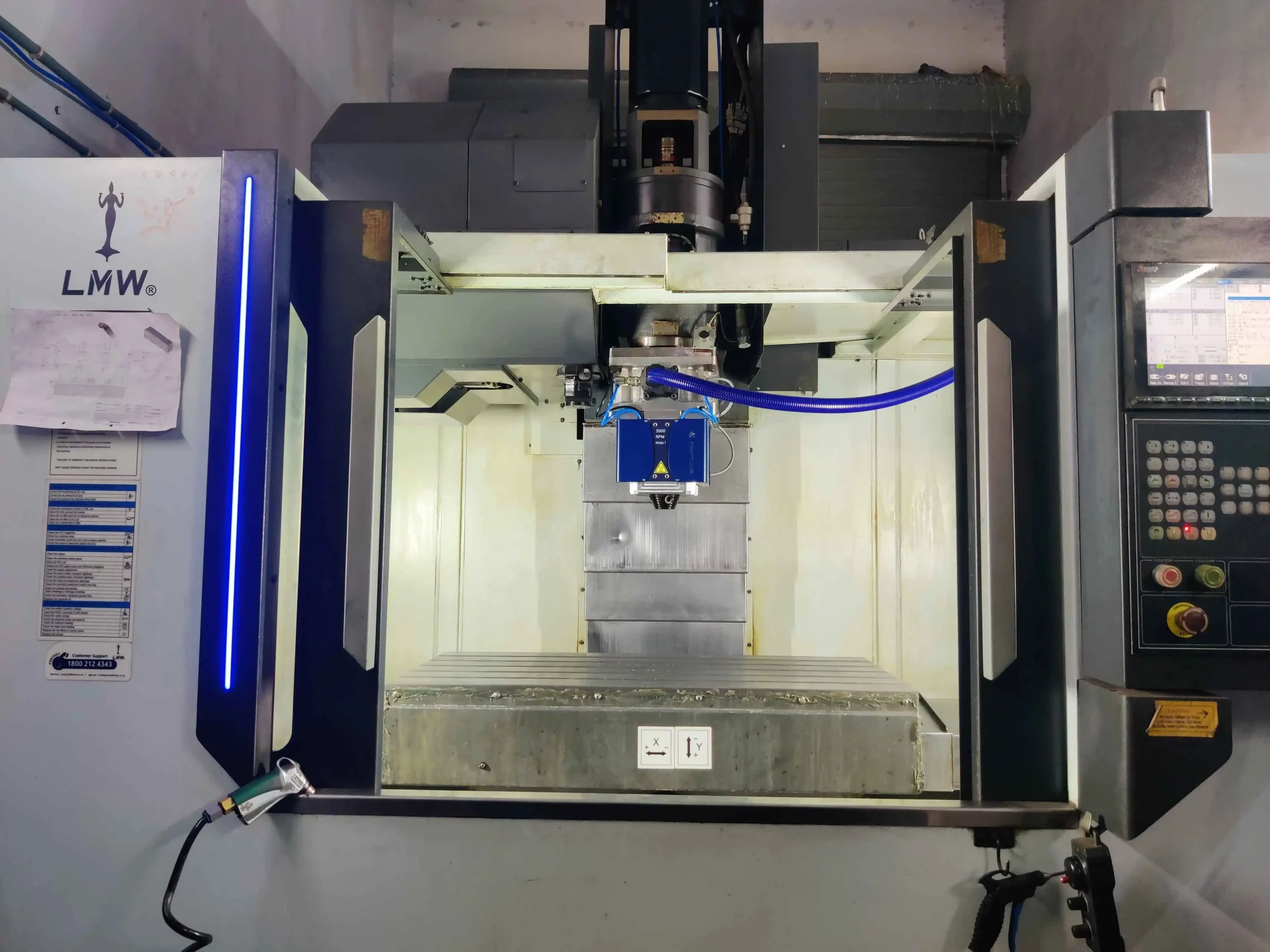

The compatible FSW equipment from our company can turn 99% of CNC machines on the markets into a reliable precise friction stir welding system.

Whatever type of CNC machine you have, our compatible FSW equipment could provide it with:

Force Control in CNC Welding Machines

Force control to apply constant pressure on the workpiece and to assure a constant contact between tool shoulder and parts to weld.

The CNC machine already has position control for milling. This allows the tool to be positioned at a constant altitude. But, in order to carry out friction stir welding, it is mandatory that tool applies a constant pressure on the workpiece. Consequently, the Stirweld FSW head has a piston inside the system, which moves up and down to apply that constant force on the part and achieves the correct quality weld.

Stirweld force control outcomes in similar results and performance than any other FSW machines (special gantry or robots). This performance has been proven many times on aerospace and automotive application.

Tool cooling

Tool cooling that protects the machine from the temperature.

Tool cooling is substantially important, to avoid the overheating of the machine that could damage it. However, we must not forget that in order to carry out defect-free welding it is necessary to reach at lears 70 percent of the melting point of the alloys to weld. For aluminium alloys, that represents a temperature between 400 and 500 degrees Celsius. This is owing to the weld is made in the pasty state, in other words: the solid state of the joining process.

Therefore, it is not possible to cool down as it is done during milling, by spraying water onto the tool. The reason is that the water would fall on the parts being welded and reduce their temperature. That is why Stirweld installed a closed loop system inside the FSW head that allows water to go up and down cooling the tool, but never over the piece.

Force recording

Force recording for quality control.

As mentioned above, constant force on the workpiece is essential for quality welding. Consequently, it is necessary to guarantee this constancy in order to be sure that the part is free of defects. At Stirweld, we carry out this quality control by incorporating a sensor to measure and record the force which is exerted during the friction stir welding process. As long as the force exerted lies between the minimum and maximum defined for the specific weld, we can ensure that the welded part meets the quality criteria and is free of defects.

Our software permits to control the force in real time, being observed directly on the screen during the friction stir welding procedure. Additionally, as the force control is recorded, it can be analysed afterwards.

Forces and vibrations management

FSW forces and vibrations management to protect your CNC.

During friction stir welding forces and vibrations are produced which, if not prevented, are transmitted to the CNC spindle. These can damage it when they are too high. In order to protect your CNC machines, the Stirweld FSW head offers a special protection. This allows, firstly, to cut all the possible vibrations produced during the process. And, secondly, the protection system transmits the force directly to the gantry instead of the spindle, which is strong enough to withstand the produced force without problems.

The FSW head has been mounted to date on more than 30 machine models for 3 years with high production rate with absolute spindle protection.

Maximizing efficiency and quality with Stirweld technology

Thanks to these 4 functions added to your CNC machine – whether it is a 3, 4 or 5 axis machine – you will…

Do you want to know more about this FSW equipment?

Get the answers to the questions you’re probably wondering about.