STIRWELD FSW EQUIPMENT

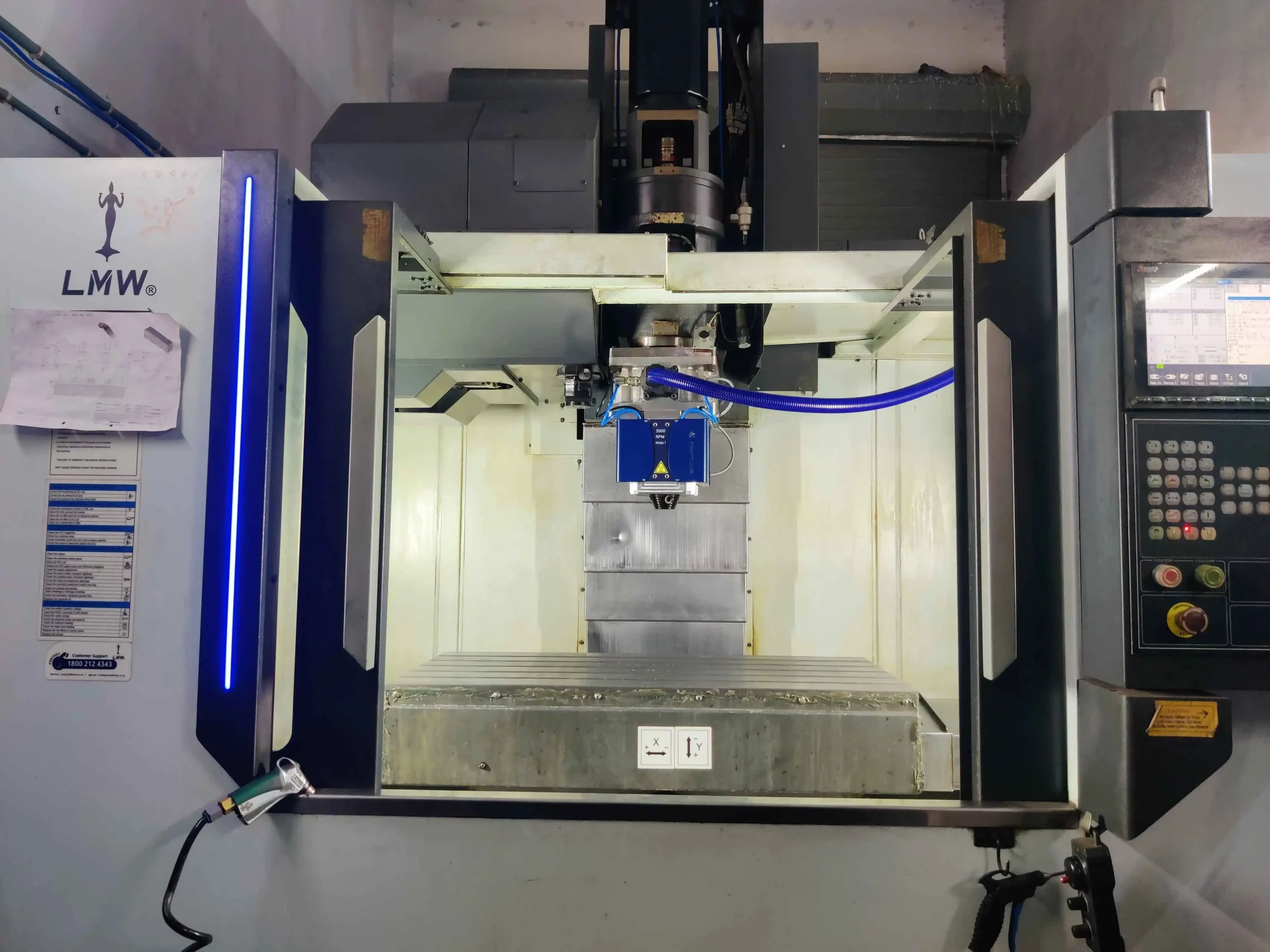

Retractable pin FSW head for CNC

Upgrade your CNC system with the latest in friction stir welding solutions. Witness unprecedented precision, efficiency and quality with our FSW head for CNC with retractable pin.

Why Equip Your CNC Machine with the FSW Head with Retractable Pin?

Cost-Effective Investment

The FSW head with retractable pin delivers a favorable ROI across all batch sizes, outperforming other FSW equipment like specialized FSW machines and FSW robots.

User-Friendly Setup

Our user-friendly setup and training process ensure that operators can quickly and seamlessly become proficient with the Stirweld FSW head featuring a retractable pin.

Optimizing Aero Welding

Elevate aerospace with this Friction Stir Welding equipment — flawless aluminum tank welds, versatile for any thickness and perfect closure of exit holes.

FSW Tech Revolution

Our retractable pin feature not only streamlines the filling of FSW exit holes but also enables versatile welding across varying thicknesses using a single tool.

Unlocking Friction Stir Welding: Key Features of the FSW Head with Retractable Pin

Force control

With an 18 kN payload and +/- 5 N accuracy, this head offers superior weld quality through forging force monitoring and precise FSW parameter tweaks.

Pin length control

Adjust pin lengths from 0-10 mm with a precision of +/- 0.01 mm. It offers unmatched precision in welding with a vertical force of up to 18 kN and retractable speeds of 0-3 mm/s.

Head Temperature

Prioritizing safety, the head features an emergency stop and dual temperature readings for consistent temperature regulation.

Head Usage

An integrated recording system monitors welding time and usage, pivotal for maintenance and consistent performance.

Warning Pop-up

A unique dual-threshold system alerts users to process deviations. Additionally, the tool meets CE certification, adhering to European safety and environmental standards.

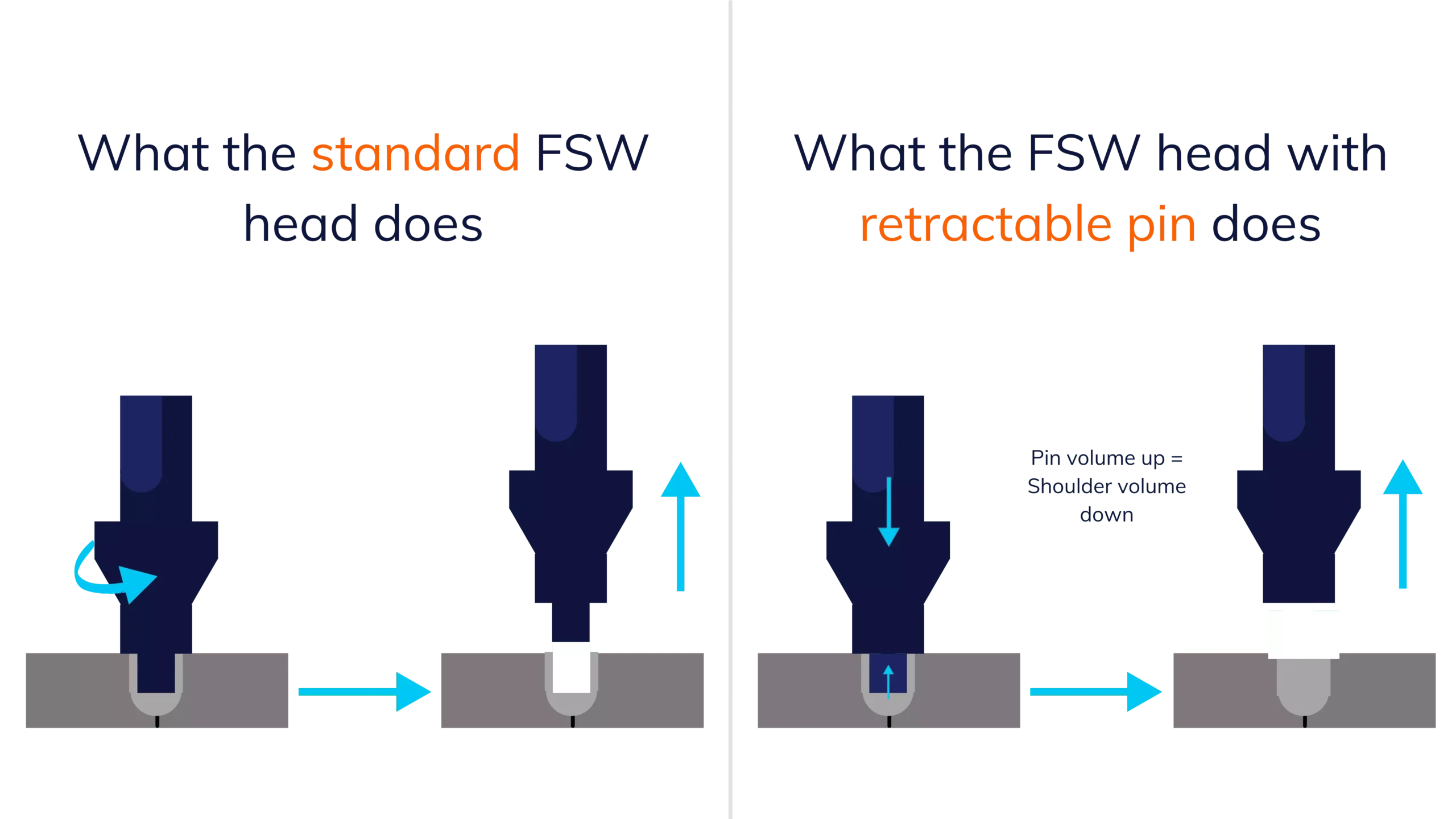

Zoom on Retractable Pin Principle

During the conclusion of a friction stir welding procedure, the tool pin typically leaves behind an exit hole. This remnant can be problematic for certain applications. However, with the FSW head for CNC with retractable pin, this issue is addressed. Specifically, the pin is designed to be retractable. Thus, at the culmination of the welding sequence, it withdraws seamlessly, ensuring no exit hole remains.

| Tool in two parts | The shoulder and the retractable pin are independent for an easy change and cost saving. |

| Torque transmission | The whistle notch attachment is designed for optimal torque transmission, ensuring that both the pin and the shoulder rotate in synchronized speeds. |

| Alignment | The alignment between the shoulder and the pin adheres to an H7/G6 tolerance specification. |

Technical Specifications of the FSW Head for CNC with Retractable Pin

Our FSW head with retractable pin has all the functions of the Standard FSW head: force control & recording, cooling, protection of the spindle against loads and vibrations. The difference is the retractable pin which enables to fill the FSW exit hole, beneficial for aerospace applications for example.

| Force control | Ensures weld quality from 1 to 18 kN |

| Welding rotation speed | Up to 3500 RPM |

| Force recording | In real time for quality assurance and make easier the welding parameter adjustement |

| Quick tool change | Whistle notch attachment with accurate positioning |

| Stiffness | Extreme stiffness (no lateral deviation of the FSW tool) |

| Cooling system | Water and air pressure cooling |

| Remote control | For production mode or process adjustment |

Human Machine Interface of FSW head with retractable pin

Tailored for optimal production and process adjustments, this Human Machine Interface adheres to the EN 9100 standard and is geared for efficiency. With a connector of 30 mm diameter, users are ensured free software updates, keeping them abreast of the latest features. It not only displays system parameters for easy process monitoring but also streamlines the management of production recipes, detailing welding parameters. Users can effortlessly launch manufacturing orders, manually control operator events and adjust the retractable pin length. For ensuring impeccable weld quality, the interface presents curves of selectable values and delivers comprehensive reports on system status.

“We wanted to evolve the tool to suit our needs. Before, we used a robot arm to carry out friction stir welding. However, there are many joints in a robot. This makes it too flexible. It deforms a little when you press on the welded surface. In an operation like FSW, you lose precision. To achieve the precision we want, we needed the stiffness of a machine tool.”

Alexia Grosso

Design Engineer

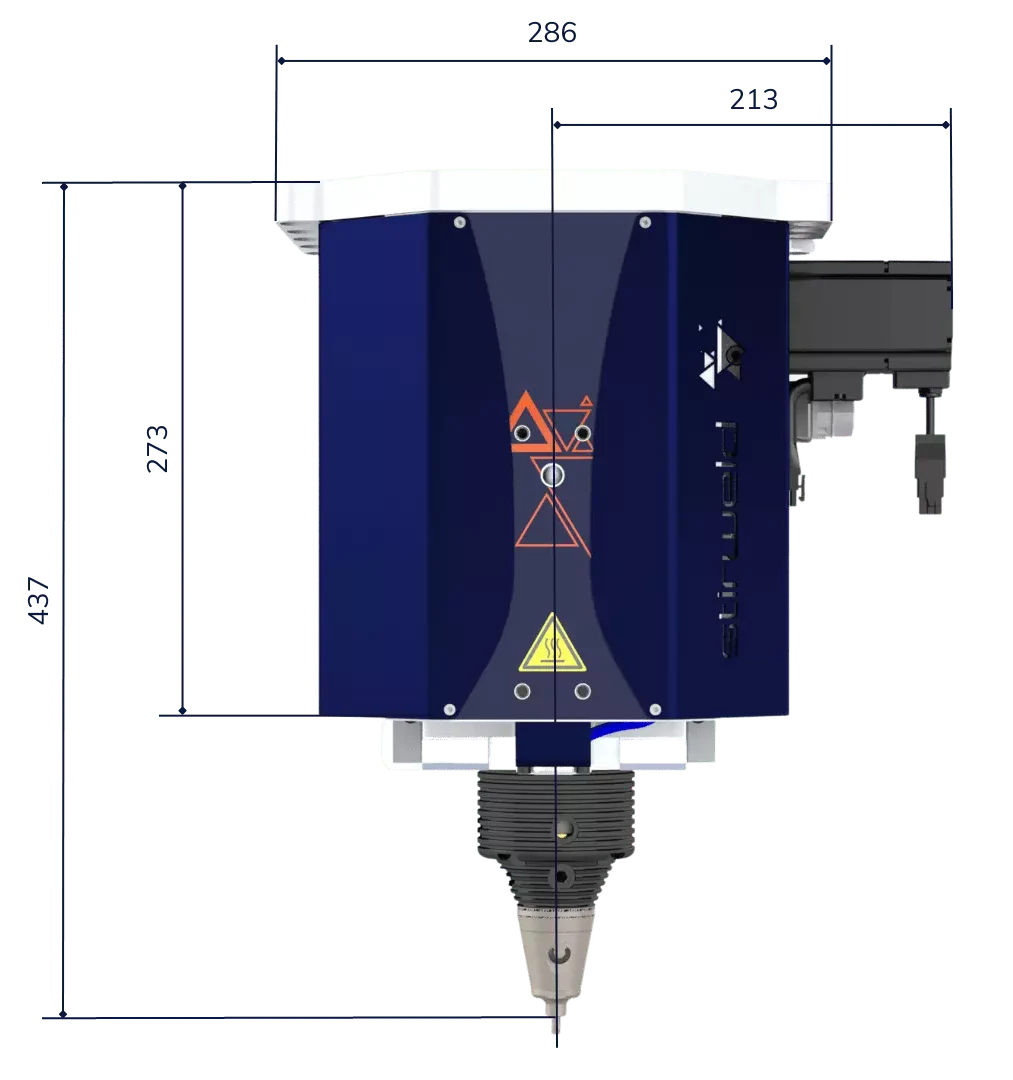

Dimensions and Machine Footprint of our FSW Head with Retractable Pin

FSW head with retractable pin dimensions

Being well-informed about the precise dimensions of the FSW head for CNC with retractable pin is fundamental to ensuring a hassle-free integration into your existing industrial setup. Every millimeter matters when it comes to achieving the perfect fit and ensuring that operations run smoothly. We’re committed to transparency and precision, which is why we provide in-depth measurements of our Retractable Pin FSW head. Each specification is a testament to our meticulous design approach, ensuring optimum performance and a seamless merging with your existing machine framework.

| Size | Height of 437 mm (17.2 in) |

| Weight | 70 kg |

| Assembly & disassembly | Completed in 15 minutes |

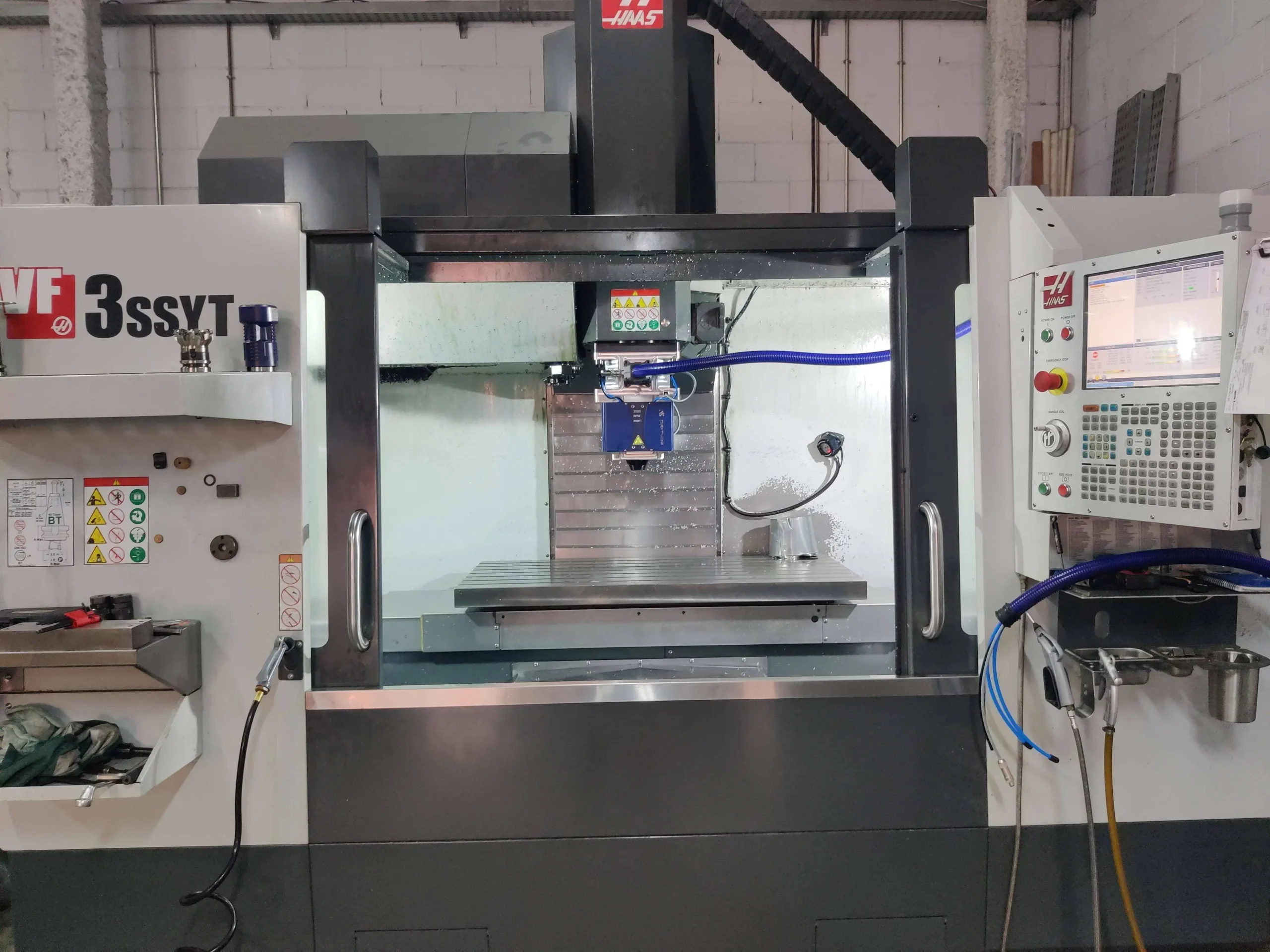

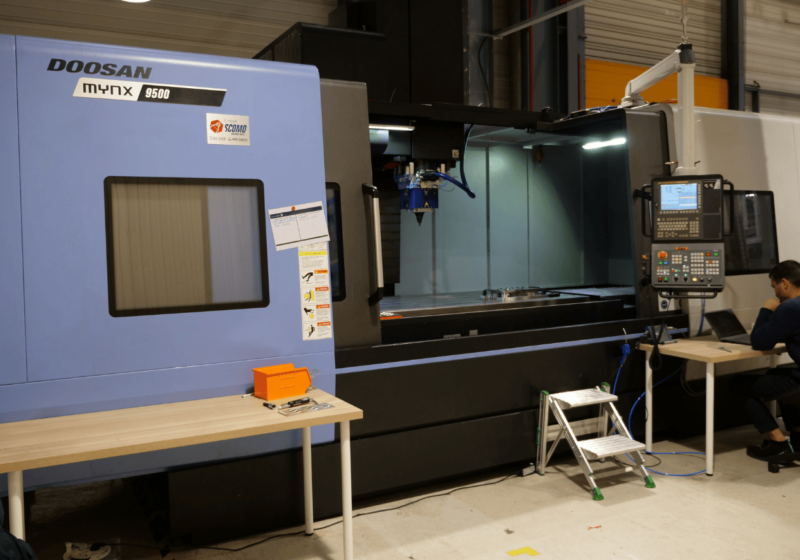

Rough estimates for integrating the FSW Head with Retractable Pin into a machining center

To determine if your machining center is compatible with our FSW head for CNC with retractable pin, consider the following rough criteria. Remember, these specifications are general recommendations and might differ based on specific scenarios. If you’re uncertain or need further guidance, our expert team is always ready to help.

A spindle power of at least 10 kW is required.

The spindle torque should not be less than 50 N.m and should be operational at an RPM starting from 1000.

The attachment size compatibility includes ISO 40, BT 40, HSK 63, or similar sizes.

Factor in a minimum clearance of 450 mm under the spindle nozzle, especially considering the FSW Retractable Pin head dimension of 437 mm or 17.2 inches.

Still curious about the intricate details of the FSW head for CNC with retractable pin? Dive deeper into its world by exploring our comprehensive article. Learn the distinct advantages of the retractable pin process compared to the fixed-pin FSW, delve into its technical specifications and discover why industries, especially the aerospace sector, are leaning towards this innovation. For those seeking a more profound understanding and insights into the nuances of this equipment, our article about FSW without exit hole is a must-read!

Ready for Friction Stir Welding Without an Exit Hole?

Embark on your journey with the FSW head for CNC with retractable pin and elevate your welding processes. Reach out to us for a tailored quotation that matches your unique needs. Let’s collaborate and find the perfect fit for your operations!