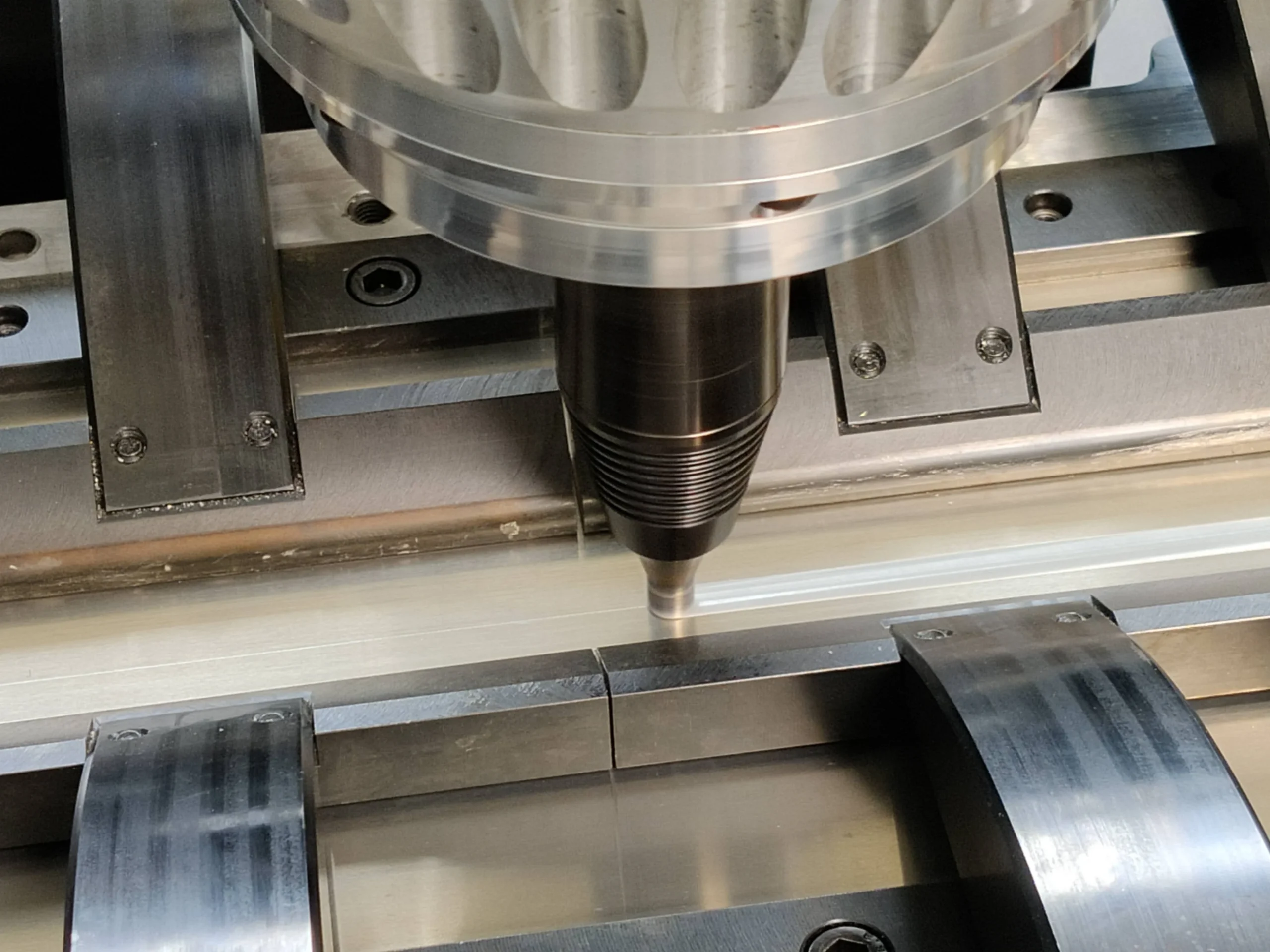

FSW machine: choose the best option

Dedicated machine, robot or FSW head for CNC machine?

You are interested in Friction Stir Welding technology but not sure how best to invest in it, you are at the right place! Let’s review step by step the different characteristics to take into account when choosing a FSW solution.

Friction Stir Welding: investment cost

Without a doubt, price is a very important criterion that must be considered account when choosing the FSW solution that best suits your needs. We sometimes think that price is intimately linked to quality, that is: the more expensive a product is, the better it is. However, this idea could not be further from reality. Let’s see why:

When we talk about dedicated FSW machines the price can vary considerably. Starting at 600,000 euros we can obtain an FSW machine that allows us to weld 2 meters long. However, if we need to weld a longer length, this price will be increased. For example, if we need to weld more than 10 meters, the investment would amount to 2 million euros. But why such a high price? The answer is simple: FSW dedicated machines are produced as a single unit (without using mass production principle).

As for the robot, we must go piece by piece. The robotic arm is mass produced and therefore its price is reduced (about 100,000 euros). Nevertheless, this arm cannot perform FSW welding on its own: an FSW head must be attached to it, it must be integrated through barriers and the entire software environment must be developed. All this, produced in a unitary way, is what will cause a FSW robotic workstation to increase its price, reaching 400,000 euros.

The Stirweld solution consists of adding an FSW head to a machining CNC center, which greatly reduces the cost of investment from the outset. Futhermore, this FSW head is mass produced. For this reason, the cost of the Stirweld FSW head is less than 100,000 euros, a much more advantageous price than the other FSW solutions.

FSW welding thickness

Depending on the application for which you will use FSW technology, the thickness of the weld will be different. 95% of the applications on the FSW market are less than 5mm thick, however, this may not be the case for your application. Take a look at the welding thicknesses that the different FSW solutions can achieve to see which one suit your application best.

A dedicated FSW machine can apply a very important welding force, normally up to 60 kN. Bearing in mind that 2 kN is equal to about 1 mm of weld thickness, the dedicated FSW machine can achieve up to 30mm.

The welding force of the robot arm is limited to only 10 kN. Therefore, the thickness of its weld is drastically reduced to 5mm.

The welding force of the Stirweld FSW head is 25 kN, which positions it as the intermediate option for this feature. With the FSW head, it is possible to make welds with a thickness up to 12mm and 20 mm in double side weld configuration.

FSW machine: delivery time

Once you decide to invest in friction stir welding, it makes sense that you want to have access to it immediately. In addition, FSW technology is undoubtedly a great competitive advantage that should be exploited as soon as possible.

The special FSW machine is manufactured on demand. This means that, once requested, the process of design, construction, assembly, etc. is started from the beginning. Therefore, the delivery time of an FSW special machine is remarkably long: between 12 and 18 months.

The same applies to FSW robot and consequently their delivery time is also long. Normally its delivery time is around 6 months.

However, the manufacturing cycle of the FSW head is very short, so it could be available in just 3 months. In addition, Stirweld has FSW heads in stock, which reduce the delivery time to as little as one month.

Friction Stir Welding accuracy

The precision of the FSW tool position in relation to the piece when performing friction stir welding is truly important to achieve quality welds. Let’s see below which of the FSW solutions achieves the best accuracy:

The dedicated FSW machine is very precise. Specifically, it has an accuracy of 0.01 mm.

In the case of the FSW robot, the accuracy is 1 mm. This low accuracy is due to the low stiffness of the robotic joints and, thus, the important elasticity of serial robots. Consequently, the robot deformations under the high FSW forces cause a lateral FSW tool deviation impacting the weld quality.

The Stirweld FSW head has the same level of accuracy as a special FSW machine, which means an accuracy of 0.01 mm.

Force control in Friction Stir Welding

In order to produce quality friction stir welds, a constant force must be exerted on the workpiece. This is why force control is mandatory and can be found with the same level of quality on dedicated FSW machines, FSW robots or FSW head for CNC machine.

Footprint of a FSW machine

When you want to bring in-house a new technology, you should take into account the space that all the machinery will occupy since it is required to fit in your workshop. For those workshops of small or medium sizes, as well as for those who already have a high number of machines, this feature can make the difference between access to such technology or not.

A special FSW machine has a very large size and, therefore, it will be necessary to have a large space where to position it.

FSW robot is generally more compact than a special FSW machine. However, it is also necessary to take into account that a space has to be prepared in the workshop to set it up.

In the case of the FSW head, the footprint is almost zero. This is due to the fact that the head is added directly to a CNC machine already in the workshop.

Modularity of your FSW equipment

Although the main interest is to perform friction stir welding, it is also recommended to take into account the modularity of the solution in order to perform other actions: this saves time and money.

The special FSW machine does not have any kind of modularity, since it can only perform friction stir welding.

FSW robotic station can also only perform friction stir welding. However, its modularity is considered to be greater, as it could be reconfigured to perform another operation in the future, such as picking.

The Stirweld FSW head allows the highest level of modularity as it directly transforms the CNC machine into a hybrid machining-welding machine. Since the FSW head is assembled and disassembled in only 10 minutes, it allows access to the CNC machine whenever needed. But it is also possible to carry out small milling operations by simply changing the FSW tool to a milling tool (limited to a speed of 6000 rotations per minute).

Rigidity of the FSW machine

The rigidity of the FSW solution is important as it is directly linked to its accuracy.

A dedicated FSW machine is totally rigid and therefore also totally accurate.

The FSW robot is not rigid and, due to this, it loses precision.

The FSW head for CNC machine has the same level of rigidity and accuracy as a special FSW machine.

Friction Stir Welding: work envelop

Depending on the application for which friction stir welding is going to be used, this can be an important feature. If your intention is to weld large surfaces, read on:

The size of the friction stir welding performed by a dedicated FSW machine is limited to the size of that machine.

The performance of a robotic FSW station is not limited, since the robotic arm allows friction stir welding both in front and behind it. In addition, it would be possible to use a rail to move it as much as necessary.

The work envelope of the FSW head is limited by the size of the CNC machine to which it is added. Therefore, with an FSW head it is possible to perform large welds as long as the CNC machine allows it.

3D welding in Friction Stir Welding

The same applies to the possibility of 3D welding. Depending on the application for which you are going to use friction stir welding, you may find this an important feature when choosing your FSW solution or not. However, 95% of the FSW applications on the market are only made on a flat (2D surface).

In the case of a dedicated FSW machine, it can only weld in the horizontal plane.

The FSW robotic station can weld in 3 dimensions: it can weld horizontally, in reverse, vertically… any way that can be imagined.

When we talk about the FSW head for CNC machine, this feature is directly linked to the CNC machine. If it is a 3-, 4-or 5-axis machine, it will be possible to weld in 3 dimensions. However, this is a more limited movement than a robotic arm.

FSW welding speed

Finally, as for the speed of friction stir welding, whatever FSW solution you choose will have the same performance: up to 3 m/min.

We have reviewed all the features that are taken into account when selecting the FSW solution that best suits your needs. As we know it is a lot of information, here is a clear summary:

Now that you have all the information you need, it’s your turn to think about which solution is the right one for you. Which feature do you give most priority to? Investment, accuracy, delivery time, modularity…?

Keep in mind that if you are a newcomer to FSW technology, opting for the FSW head for CNC machine will make things much easier for you, as the Stirweld experts will guide you in your first FSW projects. Moreover, our technical hotline is available following the installation of the FSW head for a start in complete serenity.

Do you want to know more about the FSW head?

If you want to know more about the FSW head for CNC machine solution, do not hesitate to contact us without any commitment.