Friction Stir Welding: The future of aluminium welding

Friction stir welding of aluminium parts is simple, repeatable, and affordable. However, this welding technology is still barely known to many. Read on and find out why you should know about it!

The aluminium sector is booming — it’s the fastest-growing light metal, expanding at a rate of 6% per year!

Its use spans a wide range of industries: from window frames to automotive heat sinks, aluminium stiffened panels, and aircraft components.This diversity of applications is largely due to the unique properties of aluminium alloys: low density, non-toxic, excellent thermal conductivity, corrosion resistance, and the ability to be easily formed, machined, or cast.

It’s also the sixth most ductile metal and the second most malleable.

And above all, its standout advantage is its lightness.

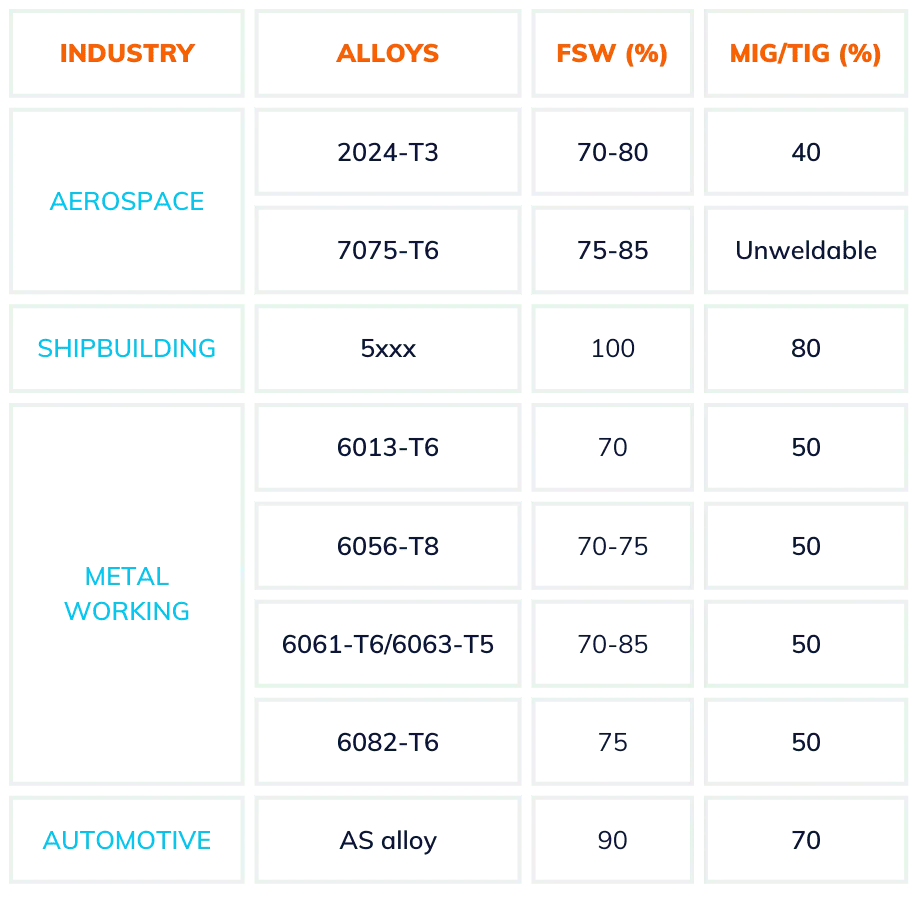

Every sector involved in transport is increasingly turning to aluminium, seeking efficient and economical solutions for processing and assembly. That’s why, when it comes to the welding of aluminium, the high performance of the Friction Stir Welding process is widely recognised — especially for its consistency and strength.

This innovative welding technology continues to evolve rapidly and is already used in a wide range of applications: automotive, aeronautics, space, energy, and even nuclear.

Today, aluminium is truly everywhere. It is used in the construction of aeroplane fuselage components, launchers like rockets, boat covers, and many car parts — including heat sinks, inverters, and thick aluminium structures.

Friction Stir Welding Technology: Advantages for Aluminium Welding

Economic Advantages of FSW for Aluminium Welding

If we talk specifically about the Stirweld FSW head, we find two great advantages to add: the investment is limited since the welding is carried out on an existing CNC machine and the head is available for renting (starting from 1900 € / month).

Technological advantages of Friction Stir Welding for aluminium welding

Environmental and social advantages of Friction Stir Welding for aluminium welding

FSW technology has been proven to be highly effective for the welding of aluminium parts. What are you waiting for to learn more about it?

Download the white papers about FSW technology

Find all the detailed information about the specific topic you are interested in:

Interested in finding out more?

Contact our experts in FSW technology.