STIRWELD FSW EQUIPMENT

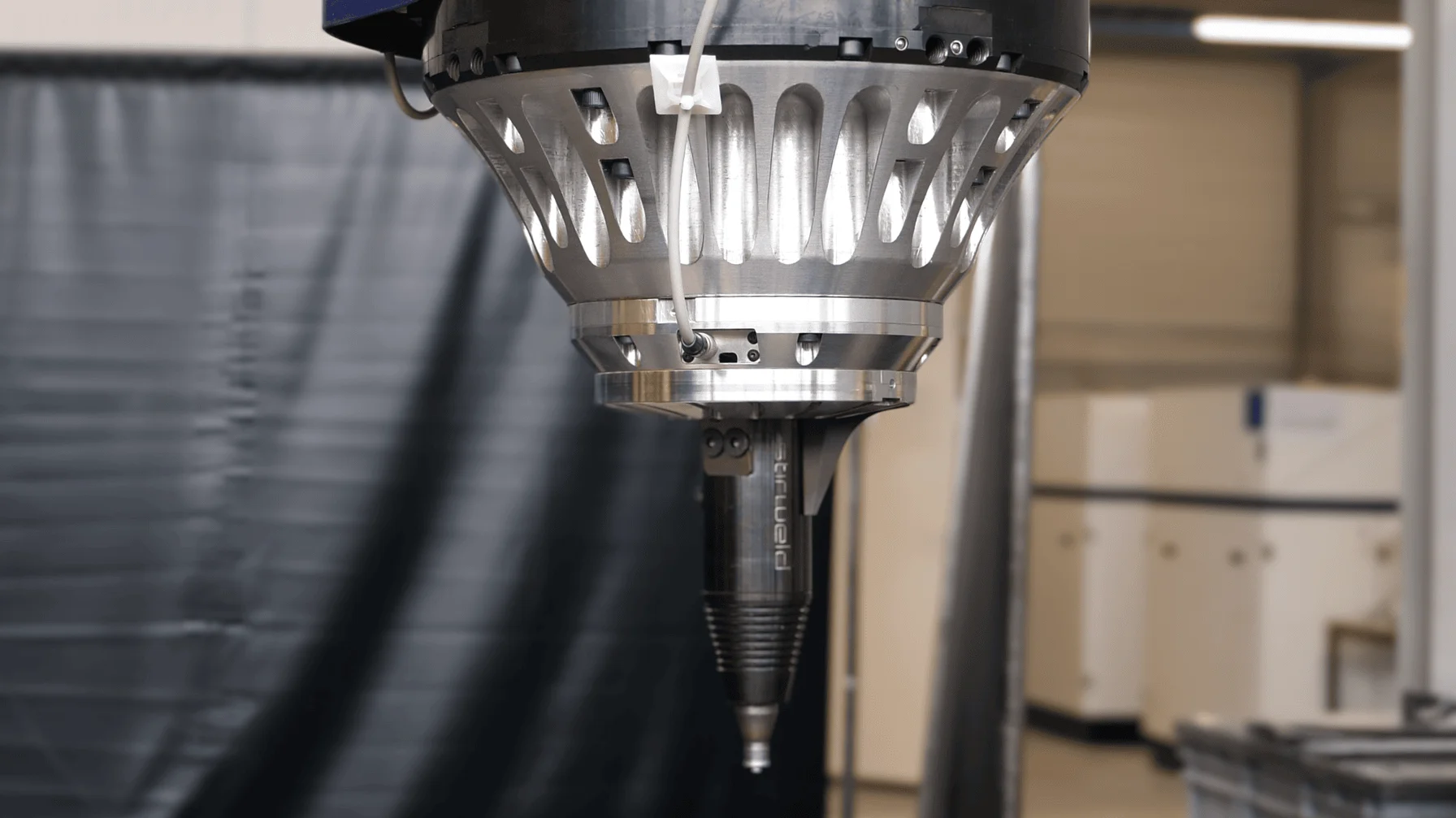

FSW Smart tool holder

Accurate temperature monitoring for superior quality welds during your welding processes.

Enhance your FSW operations with our Smart Tool Holder

No battery

Ensures continuous 24/7 operation through direct wire connections, eliminating the need for batteries.

Quality assurance

Achieves 100% quality assurance through a suite of five non-destructive testing methods.

Digital output

Utilizes a digital output to ensure signal integrity and prevent any form of signal disturbance.

Process Enhancement

Monitors tool temperature in real time during the Friction Stir Welding process for optimized performance.

Unlocking High Quality Friction Stir Welding: Key Features of the FSW Smart Tool Holder

The FSW Smart Tool Holder by Stirweld represents a significant advancement in welding technology, offering an innovative solution for real-time temperature monitoring during the Friction Stir Welding process. This sophisticated device is integrated with two temperature measurement sensors within the FSW tool, ensuring precise temperature control with an impressive accuracy of +/- 2°C. Designed with reliability in mind, the tool holder employs a full wired system, thus eliminating any dependence on wireless communication such as radio, Wi-Fi or Bluetooth, which can be susceptible to interference.

The numerical outputs provide clear, quantifiable data that can be easily interpreted for consistent welding results. The Smart Tool Holder is truly a game-changer, poised to enhance quality and efficiency in FSW applications.

Maximizing FSW Weld Quality: The Critical Role of Temperature Measurement

Master Temperature Measurement during FSW

Gain unparalleled control over your FSW process with Stirweld FSW Smart Tool Holder, your solution for precise temperature monitoring. Reach out now to elevate your welding operations.