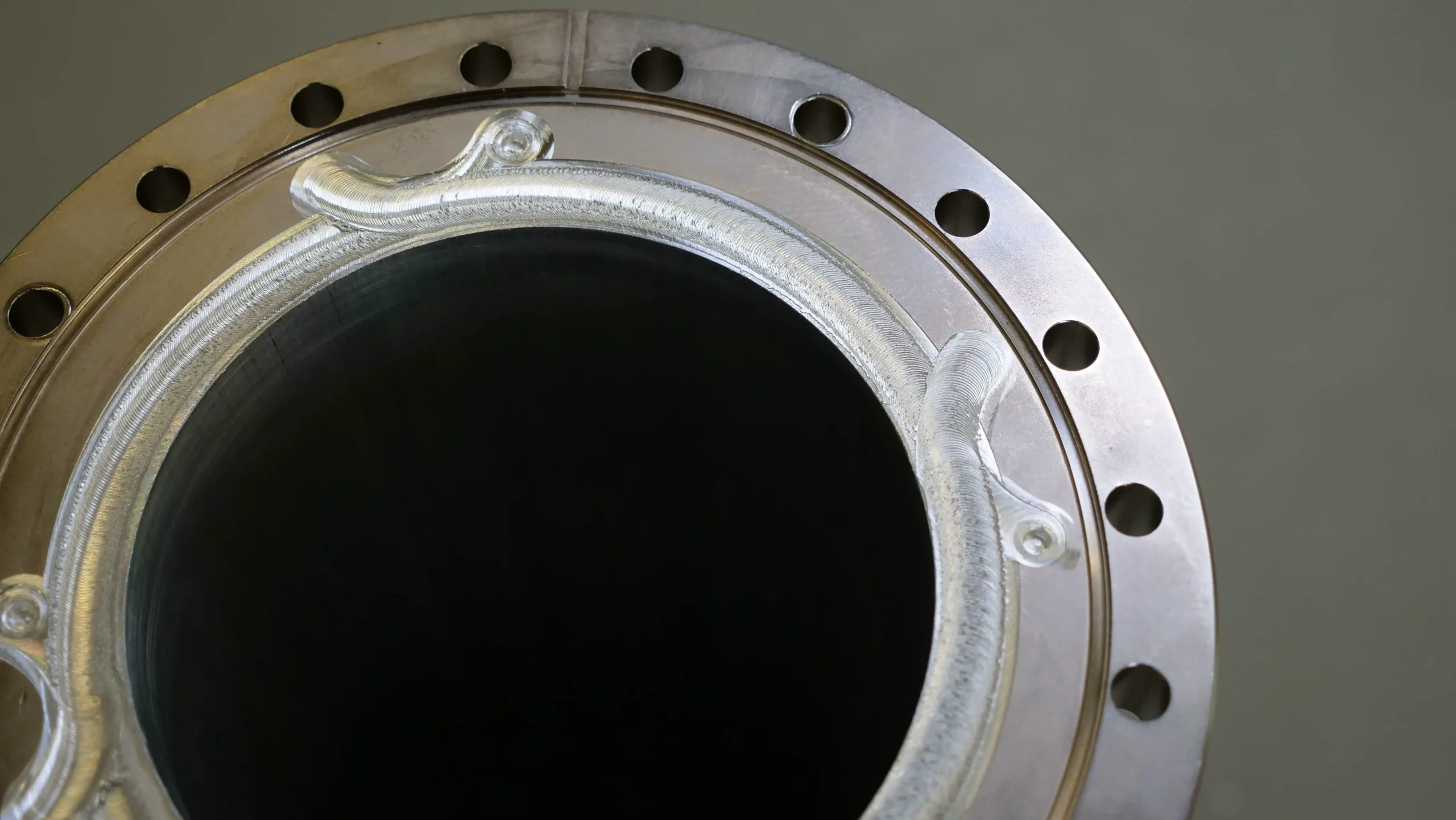

FSW APPLICATION

Flange Builders Welded by FSW

Enhanced technical characteristics of flange builders through Friction Stir Welding.

Why Choose Friction Stir Welding for Your Flange Builders Assembly?

Friction Stir Welding offers a reliable and economical solution for constructing aluminum flanges. Demonstrating no leakage over a decade, FSW produces flanges that are not only leak-proof and non-magnetic but also exhibit low nuclear activation. Furthermore, this method is up to ten times more cost-effective compared to alternatives like copper, brazing or conventional welding techniques.

Leak-Proof Reliability

Achieve 100% leak-proof joints with solid-state welding, ensuring long-term durability.

Non-Magnetic & Low Nuclear Activation

Made entirely from aluminum, offering non-magnetic properties and minimal nuclear activation.

Cost-Efficient Solution

Save up to 10 times on costs compared to copper tubing, brazing, or traditional welding methods.

Technical Specifications of FSW-Welded Aluminium Flange Builders

See Friction Stir Welding Applied to Flange Builders in Real-Time

Aluminium Flange Builders: Key Concerns for Critical Sectors

Aluminum flange builders are widely utilized in diverse industry sectors thanks to their light weight, resistance to corrosion and superior thermal conductivity. Key industries that capitalize on these distinct advantages encompass medical technology, energy, aerospace and specialized vacuum technology fields.

Medical

Precision Sealing

Energy

Reliable Power

They Trust Us

Dive Deeper: Comprehensive FSW Resources

Immerse yourself in the world of Friction Stir Welding technology through webinars, expertly-crafted blog articles and comprehensive whitepapers.

Webinar – 40 min

All you need to know about Friction Stir Welding

Join our webinar to gain insights into the innovative aluminum welding process known as friction stir welding. Explore its mechanics, applications, comparative advantages, limitations and optimization strategies for your technological processes.

Blog articles – 5 min

4 essential elements for high quality FSW welding

Friction Stir Welding: a revolution in aluminium welding

White paper – 20 min

Friction Stir Welding: principles & trends

Explore the nuances of FSW with our white paper. Discover its operational benefits, distinctive product strengths, economic advantages and stay updated with the latest market trends

White paper – 20 min

Friction Stir Welding: applications

Discover our comprehensive Friction Stir Welding application guide in this white paper. Explore various applications where friction stir welding provides numerous benefits.

Ready to Revolutionize Your Flange Builder Assembly?

Connect with our FSW experts today to optimize your flange solutions. Elevate your industry standards with FSW technology.