STIRWELD FSW EQUIPMENT

Standard FSW head

for CNC

Transform your CNC into a state-of-the-art friction stir welding powerhouse. Discover precision, efficiency and unmatched quality with our Standard FSW Head.

Why Equip Your CNC Machine with the Standard FSW Head?

Cost Efficiency

The FSW head is far more economical than dedicated FSW machines or robotic stations. It can be fitted to an existing machining center, eliminating the need for a complete equipment purchase.

Financing Option

Under financial control, we offer a compelling financing option. The FSW head becomes an affordable choice, available from just €1990 per month, ensuring you get value without compromising on quality.

Quick Setup

Its setup is a breeze! In just two days, you’ll be acquainted with its operation, ensuring a swift transition to production. Plus, with ready-to-ship inventory, we guarantee delivery within a month.

Continuous Support

Our commitment goes beyond the sale. We provide ongoing support with FSW experts ready to assist during and after head integration, guaranteeing top-notch service and assistance.

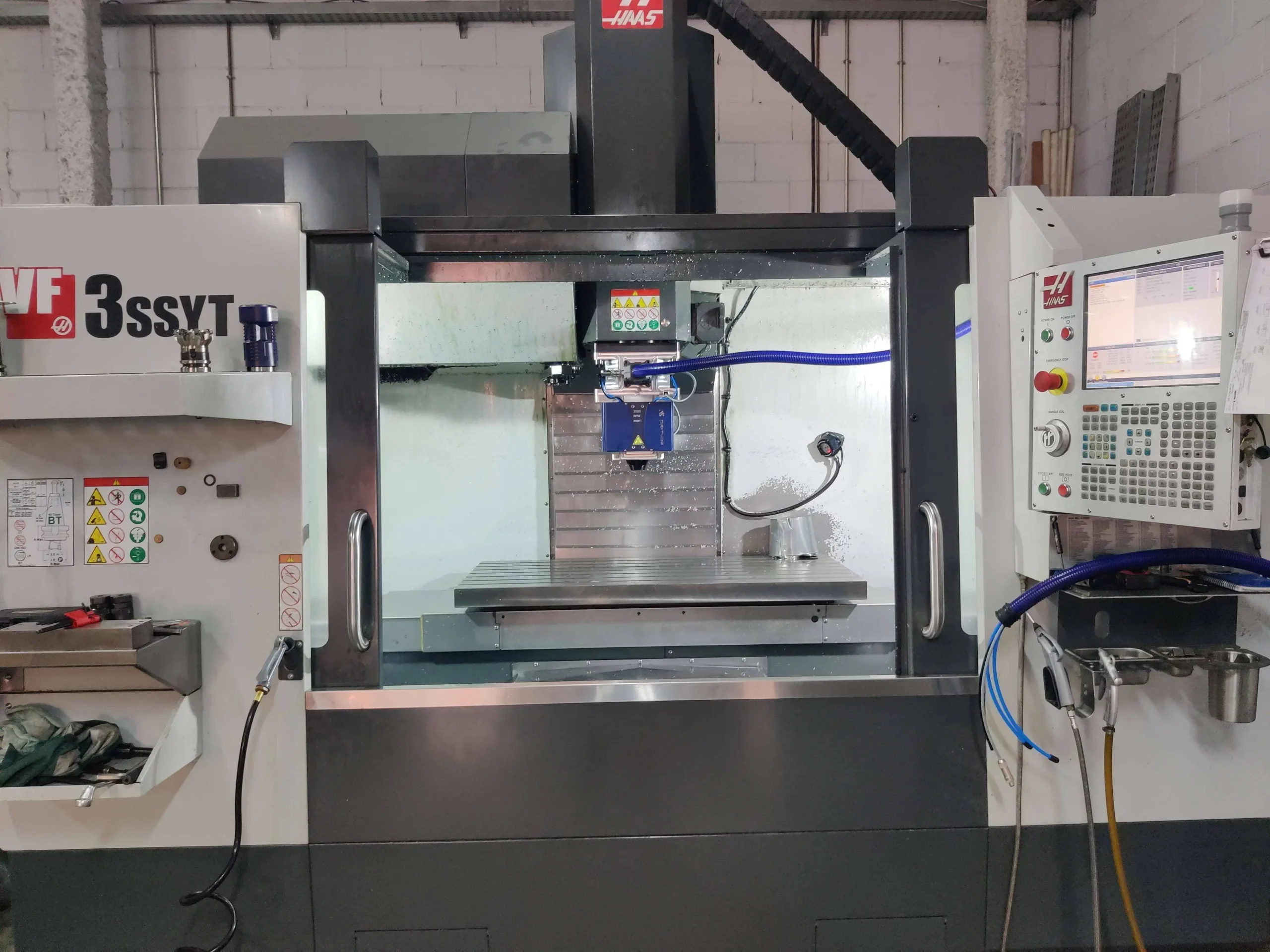

Is your CNC machine compatible with the Standard FSW head?

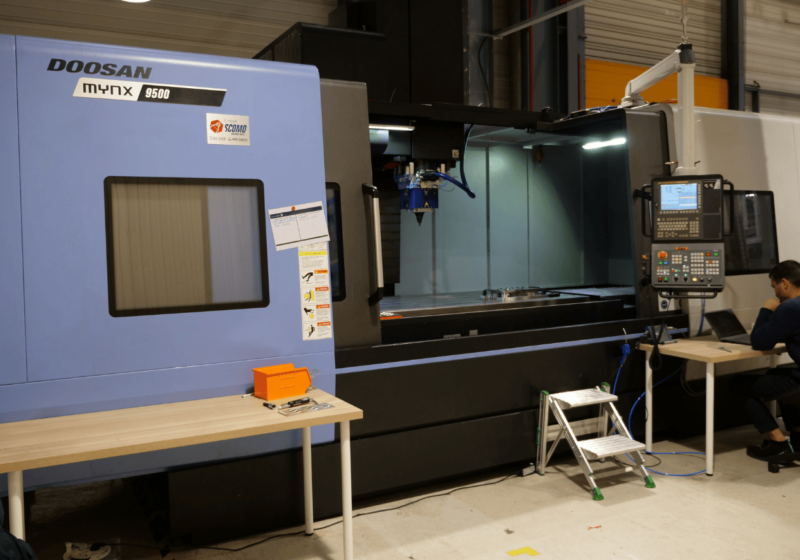

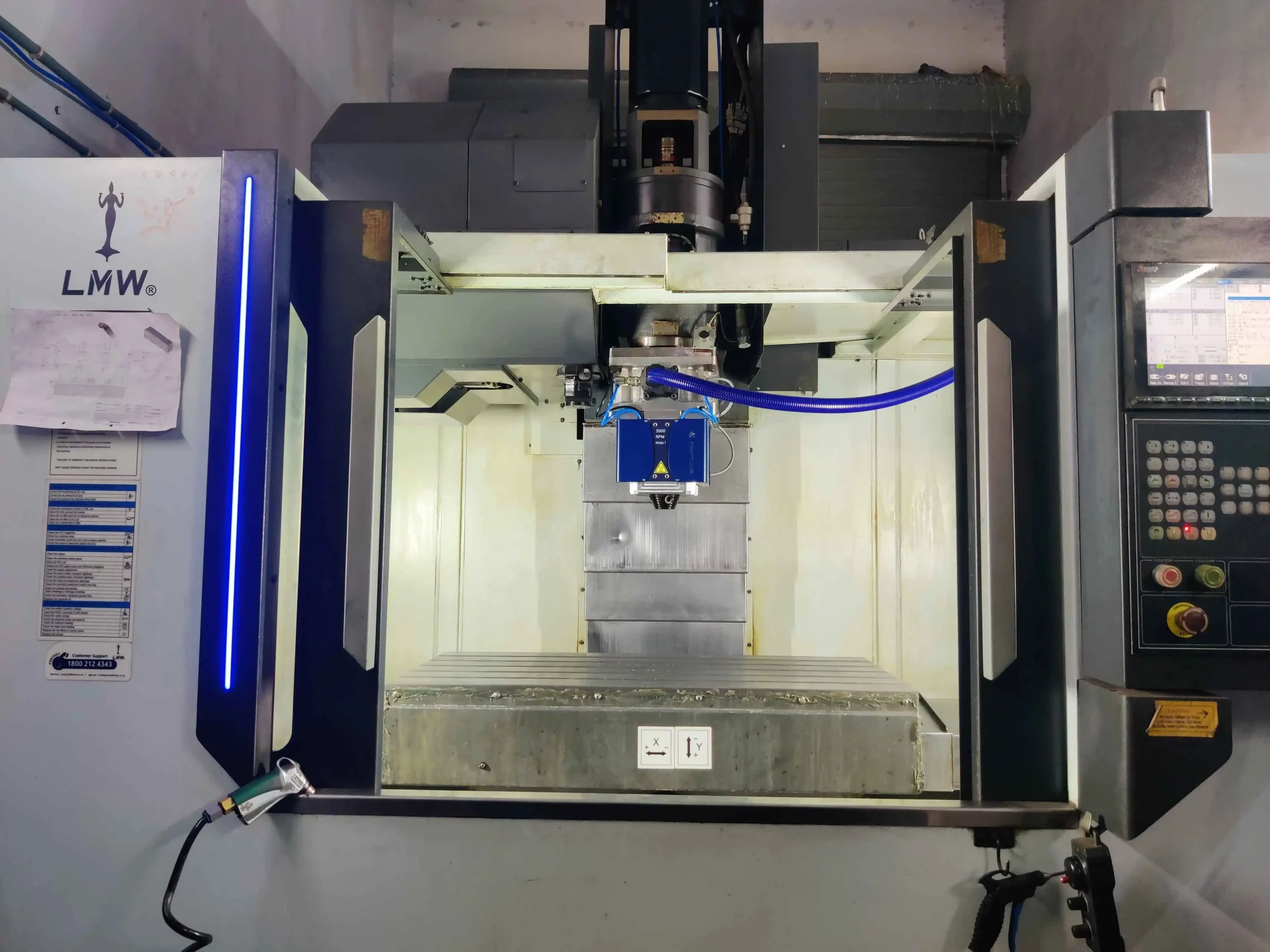

Our FSW head effortlessly adapts to 3, 4, or 5-axis machines. While we’ve showcased just a few installations, know that our head is compatible with 99% of CNC machines on the market.

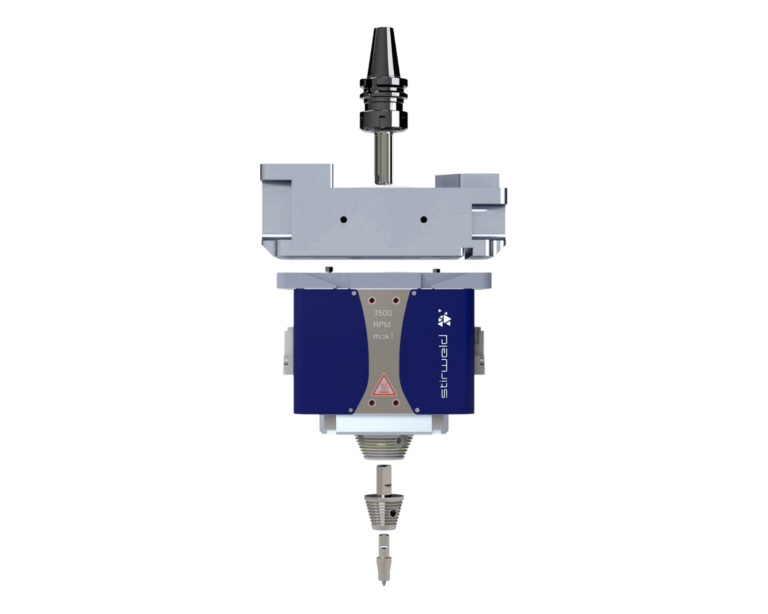

Unlocking Friction Stir Welding: Key Features of the Standard FSW Head

Force control

Ensures consistent tool penetration for high-quality welds, mitigating defects like flash and wormholes as per ISO 25239 standards.

Force recording

The control interface tracks welding force, enabling repeatability and real-time quality oversight.

Tool cooling

Water and air work in tandem to provide continuous cooling, ensuring constant weld quality and enhancing the FSW head durability.

FSW forces & vibrations protection

A specialized coupling designed by Stirweld engineers protects against machine vibrations during welding operations.

Interested in delving deeper into how our FSW head upgrades your CNC machine to a powerful FSW welding machine? Dive into our in-depth article: Upgrade your CNC machine to a FSW machine

Technical Specifications of the Standard FSW Head

Designed by friction stir welding and machining experts, the Standard FSW head integrates advanced technologies. With its 2015 patent from the SATT (a French governmental organization), this tool incorporates unique technical features for premium FSW operations.

| Force control | Ensures weld quality from 1 to 18 kN |

| Radial force | Up to 5 kN |

| Welding rotation speed | Up to 3500 RPM |

| Force recording | For quality assurance |

| Quick tool change | Whistle Notch system with precise positioning |

| Milling rotation speed | Up to 6000 RPM |

| Stiffness | Extreme stiffness (no lateral deviation of the FSW tool) |

| Assembly & disassembly | Completed in 15 minutes |

The Standard FSW head boasts a control interface (powered using 110 V or 220 V) for direct computer linkage, facilitating FSW process adjustments. We offer free software updates as enhancements roll out. Core functionalities include:

“With the acquisition of the FSW head from Stirweld, Talendi (formerly Bretagne Ateliers) offers its customers a new high-performance welding solution that is technological, ecological and economical. In 2021, Bretagne Ateliers has optimised its machine park by purchasing the FSW head from Stirweld. Installed on its machining centre, it enables it to offer quality, watertight, aesthetic and high mechanical resistance welds. At the end of the year, a few weeks after its installation, the FSW head was activated for a first customer who had a quick need to make welds on some of its parts. FSW technology is the ideal solution for welds with very high quality requirements and Talendi is able to meet the deadline. Barely a month later, thanks to the involvement and rigour of the teams and the collaboration between the customer and Bretagne Ateliers, the first newly welded parts were sent out.”

Damien Quillet

Sales Director

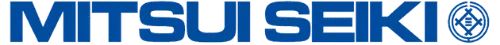

Advanced Option of Our Standard FSW Head

The Automatic FSW Head Changer enhances the Standard FSW Head by offering a sophisticated option that transforms CNC machines into truly hybrid systems. With this addition, users gain full access to their tool store, allowing for automated swapping between CNC functions and Friction Stir Welding without the need for manual tool changes. This system streamlines the production workflow, significantly conserves time and elevates machine versatility. It is an ideal solution for manufacturers aiming to integrate a more efficient, hybrid approach to their machining and welding operations, perfectly aligning with the smart manufacturing goals of Industry 4.0.

Dimensions and Machine Footprint of our Standard FSW Head

Standard FSW head dimensions

Understanding the specific dimensions of the FSW head is crucial to ensuring it fits seamlessly with your existing equipment. Detailed measurements of our Standard FSW head are provided, meticulously designed for optimum performance and effortless integration with your machine setup:

| Size | Height of 315 mm (12.4 in) |

| Weight | 35 kg |

| Water cooling | 5 l/min at 25°C (77°F) |

| Air cooling | 3 bar (43 psi) |

| Control interface | Up to 10m – 33 ft (more in option) |

Rough estimates for integrating the Standard FSW Head into a machining center

Here are rough estimates to help gauge if your machining center is suitable for our Standard FSW head. These figures are provided as guidelines and may vary. If you have any doubts, please do not hesitate to contact us. Our team is here to assist you.

The spindle power needs to be at least 10 kW.

The spindle torque should be 50 N.m minimum at 1000 RPM.

The minimum attachment size should be ISO 40, BT 40, HSK 63 or any other equivalent size.

Ensure a minimum of 350 mm under the spindle nozzle, given the FSW head height of 315 mm or 12.4 inches.

Our Standard FSW head seamlessly fits most machining centers, reflecting our dedication to promoting friction stir welding benefits. With extensive experience across varied client setups, we’ve proven the head’s wide compatibility and our team’s adaptability in meeting diverse machining needs.

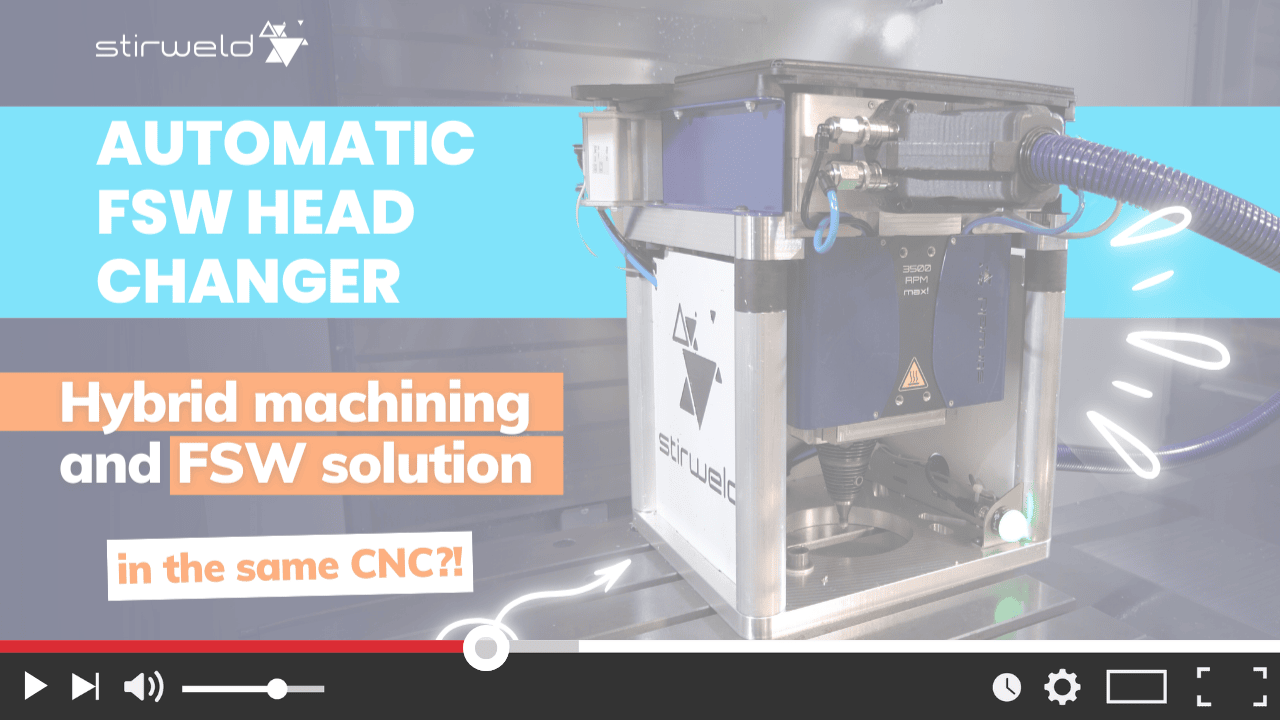

To give you a clearer picture, here you can see several examples of these installations:

Still have questions? We understand that integrating a new technology can lead to numerous queries. For detailed insights, including how the protection of both your machine spindle and operator is ensured, the impact on your CNC warranty, vibration management during the FSW process and the installation procedure of the FSW head, we invite you to explore our in-depth FSW head integration article. There, you’ll also find answers to potential concerns, such as risks associated with your CNC machine.

“Thanks to Stirweld FSW Technology, we can weld whatever application size we want on CNC machine. Friction Stir Welding gives a really good static outcome without any other operations needed. With this innovative FSW head for CNC machine, we can now diversify our operations at a very low cost and very efficiently.”

John Erian

Production manager

Frequently Asked Questions

Find quick answers to your questions with our FAQ. This section covers a range of common inquiries, providing you with immediate solutions and detailed information.

Our FSW tool does not require tilting to ensure a solid weld.

When using our FSW head on a 5-axis machine, tilting can be done. The degree of tilt of the Stirweld FSW welding head is between 0.5° and 3°.

The purpose of this position parameter is to lift the leading edge of the rotating FSW tool. The tilt thus retains the material mixed by the shoulder in the weld area.

The degree of tilt is calculated according to the friction stir welding process.

No, you do not need permission to mount an FSW head on your machining centre.

Stirweld’s welding head is universal and can be easily installed on any type of CNC. The FSW head behaves like a module added to your CNC. This FSW welding head does not involve any modification of the substance or form of your machine. The manufacturer’s warranty is therefore not engaged.

Yes, the Stirweld welding head is force controlled.

The pressure exerted on the workpiece must be constant in order to guarantee quality FSW welds. It is therefore essential to know and control the force to be applied during the FSW welding operation. This setting allows the tool to be placed on the workpieces to be welded and to ensure good compactness in order to avoid porosities. This is why we have equipped all our FSW equipment with force sensors.

A constant force of the FSW tool on the parts to be joined is essential to guarantee a quality weld.

For this reason, Stirweld has integrated a force sensor into its FSW welding head. This feature monitors the pressure exerted during the friction stir welding process. The sensor records the data and alerts the operator to significant changes in the force exerted.

The Stirweld FSW head is universal. It allows a force transducer to be integrated into any machine tool to turn your MOCN into an efficient FSW welding machine.

Yes, it is possible to switch from welding to machining and back again without disassembling the FSW head.

The Stirweld welding head was designed by experts in FSW and machining. This hybrid system allows welding and machining to take place in succession. Simply replace the FSW tool with a milling cutter. The milling add-on allows friction stir welding and simple machining or finishing of parts to be carried out easily on the same machine without human intervention.

Interested and ready to take action?

Are you ready to elevate your CNC capabilities with the Standard FSW head? Discover the full potential and benefits it can bring to your operations. For a detailed understanding and a tailored solution specific to your needs, request a quote from our team today. Invest in the Industry 4.0.