Copper-Aluminium Welding: how to overcome industrial barriers?

Friction Stir Welding (FSW) enables strong, defect-free aluminum-to-copper joints for advanced power and thermal applications.

WEBINAR March 31 2026 | Friction Stir Welding, From Fundamentals to Industrial Integration, in collaboration with TWI. REGISTER FOR FREE

Friction Stir Welding (FSW) enables strong, defect-free aluminum-to-copper joints for advanced power and thermal applications.

Friction stir welding on steel: the challenges of the Resurgam project for shipyards and shipbuilders.

Friction stir welding defects: Discover the common defects in FSW butt and lap welding : lack of penetration, flash, hooking…

Today, the environmental issue is fully linked to industry. Find out why friction stir welding is considered a green technology.

High quality FSW welding - The clamping tool, the geometry of the tool, the force control and welding parameters: 4 essential elements.

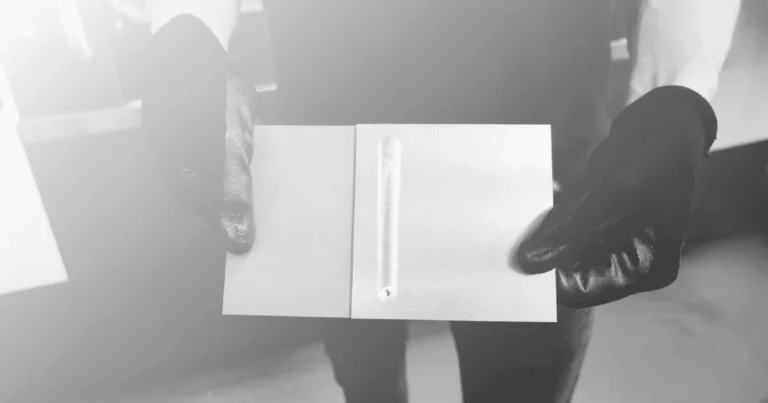

Clamping jig is specially designed to hold the parts during the FSW welding operation. Read the article to find out why it is so important!

FSW technology: Using FSW for welding aluminium parts has many technological, environmental and economic advantages. Find out what they are!

FSW design office: butt and lap welds. Differences between the two types of FSW joints. Which one suits your FSW application best?