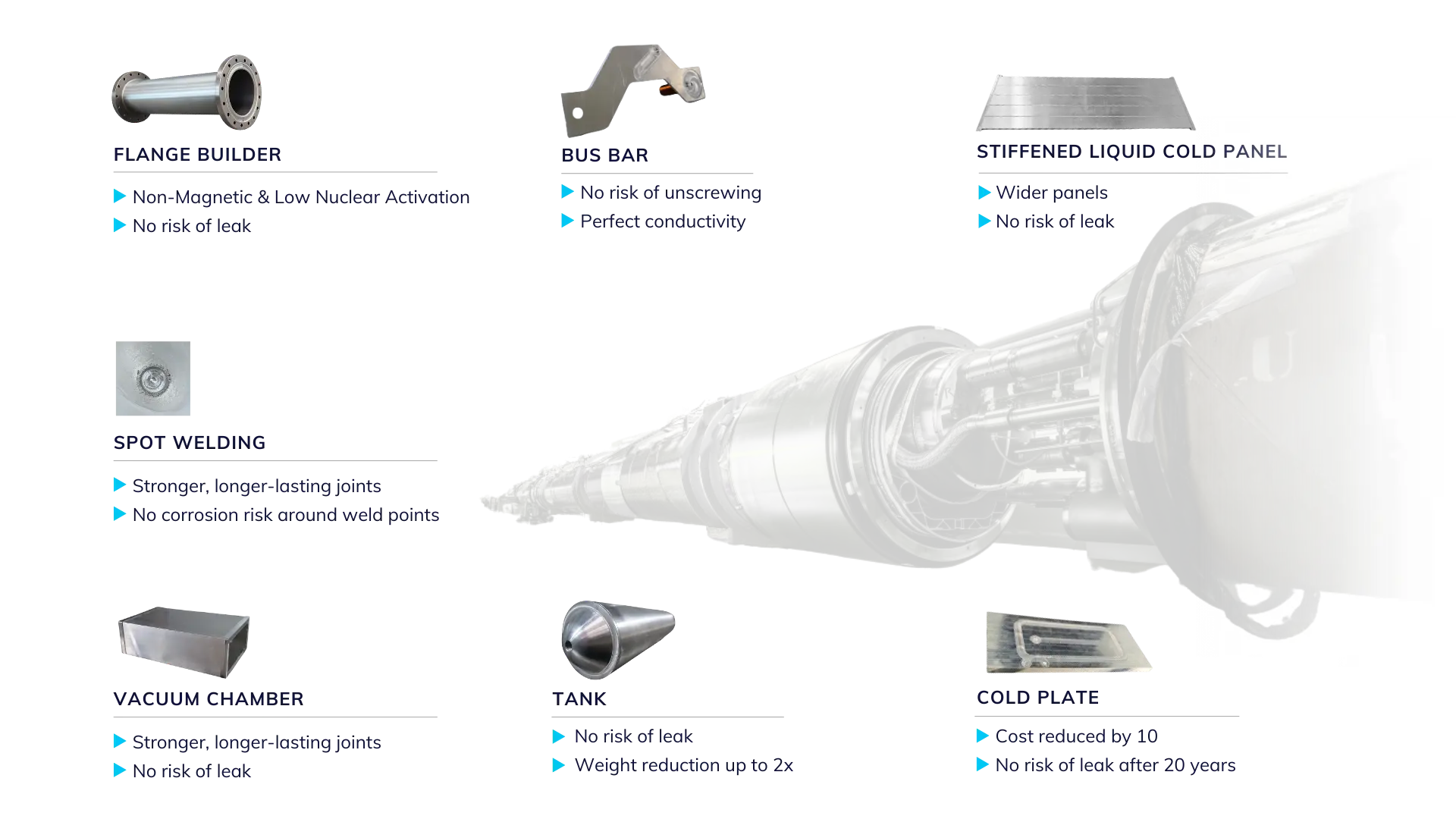

WHERE FSW TECHNOLOGY MAKES A DIFFERENCE

Friction Stir Welding in Vacuum

FSW technology elevates the vacuum industry by delivering stronger, sealed and high-quality components.

Unlocking Vacuum Industry Potential with Advanced FSW Techniques

Achieving a reliable vacuum is simplified with FSW, a cost-effective welding method that ensures durable seals and reduces maintenance needs. This versatile technique is compatible with materials like aluminum, providing consistent production quality in the demanding vacuum industry. With Stirweld, personnel can master FSW in a brief two-day training, addressing the industry’s skill shortage.

Exploring FSW Applications in the Vacuum Sector

Friction Stir Welding offers a reliable and economical solution for vacuum applications. Demonstrating no leakage over a decade, FSW produces flanges or vacuum chamber that are not only leak-proof and non-magnetic but also exhibit low nuclear activation. Furthermore, this method is up to ten times more cost-effective compared to alternatives like copper, brazing or conventional welding techniques.

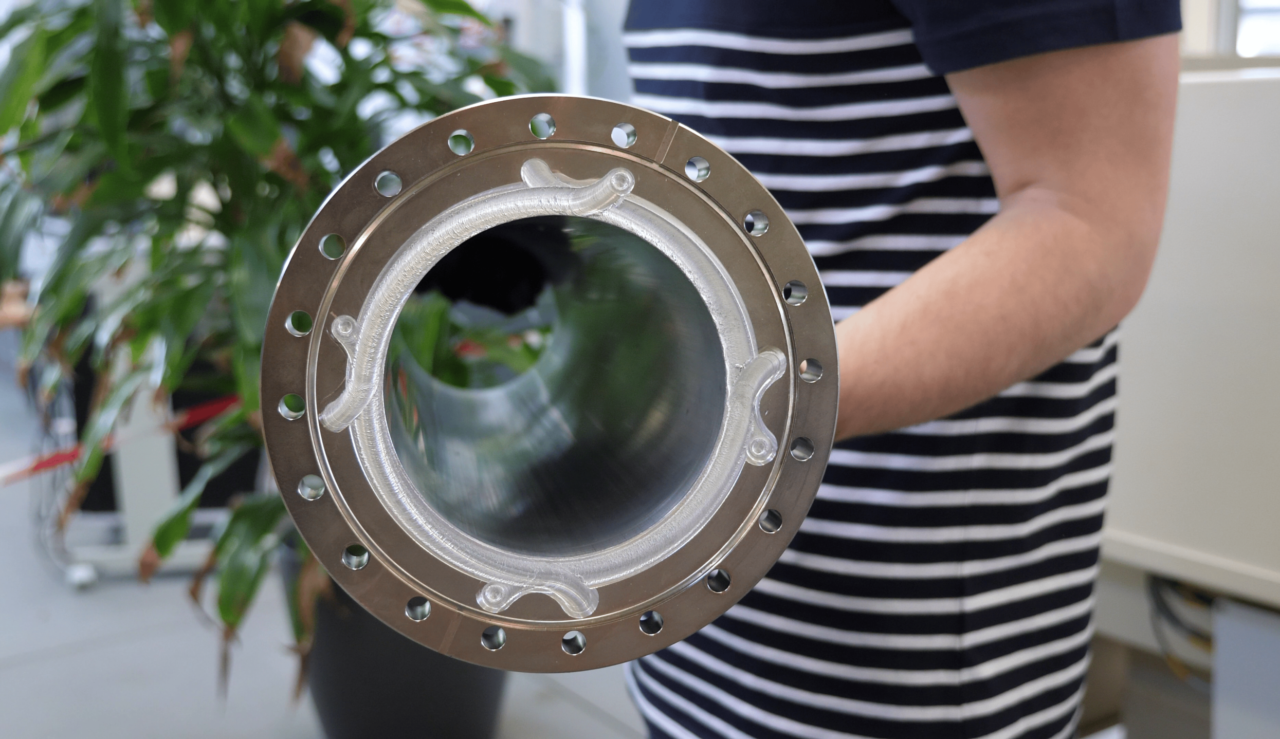

Flange builders

In the vacuum sector, aluminum flange builders are favored for their lightweight, corrosion resistance and enhanced thermal conductivity.

Vacuum chambers

Aluminium vacuum chambers stand out in the vacuum domain due to their lightweight properties, resilience to corrosion and efficient heat transfer capabilities.

Recommended FSW Equipment for Vacuum Applications

Our FSW machinery aligns with the stringent demands of the vacuum sector, delivering unparalleled quality, economic viability, and environmental responsibility. Explore the equipment our specialists suggest for your specific vacuum needs.

Standard FSW head for CNC

The Standard FSW head integrates effortlessly with 3, 4 or 5 axis machines. It offers precise force control, live force tracking, effective tool cooling and robust defense against mechanical strain and oscillations – all vital for premium FSW welding outcomes.

FSW head for CNC with retractable pin

Building on the core capabilities of our Standard FSW head, this variant boasts a retractable pin, erasing exit holes — a major boon for vacuum tasks. Its intuitive interface guarantees optimal control and flawless friction stir welding quality every time.

They Trust Us

Dive Deeper: Comprehensive FSW Vacuum Applications Resources

Curious about Vacuum Applications and FSW? We’ve curated a collection of resources, from enlightening videos to informative articles, for your exploration. Tap below to uncover the wealth of knowledge we’ve gathered for you.

White paper – 20 min

Friction Stir Welding: principles & trends

Delve into the intricacies of FSW with our insightful white paper. Discover its economic merits, unique product strengths, operational advantages, variety of equipment and prevailing industry trends.

Blog articles – 5 min

Friction Stir Welding head with retractable pin: your new FSW equipment for welds without exit hole

4 essential elements for high quality FSW welding

Elevate Your Vacuum Solutions with FSW

Ready to harness the transformative power of Friction Stir Welding in the vacuum industry? Tap into its unparalleled benefits and see how FSW can upgrade your vacuum applications. Reach out to our experts today!