Friction Stir Welding aluminium: The future of welding

Friction stir welding aluminium parts is simple, repeatable, and affordable. However, this welding technology is still barely known to many. Read on and find out why you should know about it!

The aluminium sector is booming — it’s the fastest-growing light metal, expanding at a rate of 6% per year!

Its use spans a wide range of industries: from window frames to automotive heat sinks, aluminium stiffened panels, and aircraft components.This diversity of applications is largely due to the unique properties of aluminium alloys: low density, non-toxic, excellent thermal conductivity, corrosion resistance, and the ability to be easily formed, machined, or cast.

It’s also the sixth most ductile metal and the second most malleable.

And above all, its standout advantage is its lightness.

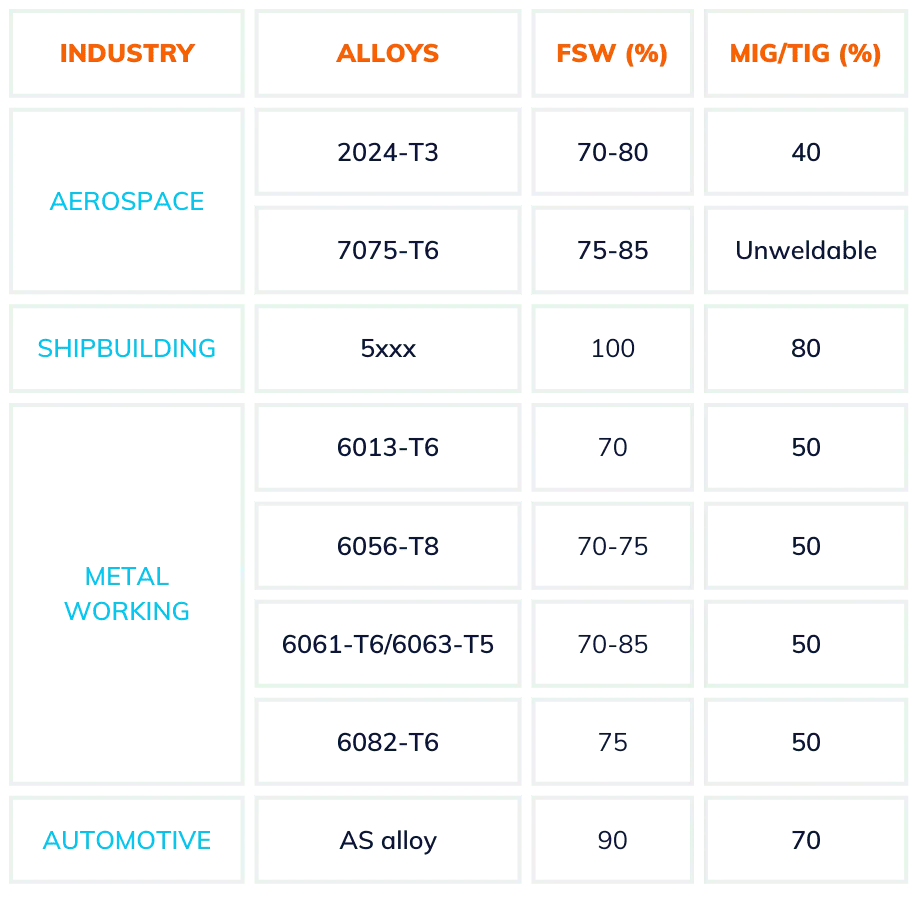

Every sector involved in transport is increasingly turning to aluminium, seeking efficient and economical solutions for processing and assembly. That’s why, when it comes to the welding of aluminium, the high performance of the Friction Stir Welding process is widely recognised — especially for its consistency and strength.

This innovative welding technology continues to evolve rapidly and is already used in a wide range of applications: automotive, aeronautics, space, energy, and even nuclear.

Today, aluminium is truly everywhere. It is used in the construction of aeroplane fuselage components, launchers like rockets, boat covers, and many car parts — including heat sinks, inverters, and thick aluminium structures.

Friction Stir Welding Technology: Advantages for Aluminium Welding

Economic Advantages of FSW for Aluminium Welding

Additional benefits of the Stirweld FSW head:

- Minimal investment since the friction stir weld is performed on an existing CNC machine.

- The FSW welding head is available for rent, starting from €1,900 per month.

Technological advantages of Friction Stir Welding for aluminium welding

Environmental and social advantages of Friction Stir Welding aluminium welding

Friction Stir Welding (FSW) has become a reference technology for the reliable welding of aluminium parts, combining strength, precision and efficiency. Beyond eliminating common defects of traditional welding, it enables cost reduction and performance improvement in a wide range of applications. What are you waiting for to learn more about it?

White papers and practical guides on Friction Stir Welding technology

Our expert guides give you access to in-depth knowledge on design rules, process fundamentals, and practical implementation steps. Whether you are new to FSW or looking to optimize your production, you will find detailed explanations, real examples and proven strategies. Choose the topic that best fits your needs and bring your projects to the next level:

11 rules for perfect compatibility with FSW

Discover 11 key design rules to make your parts fully FSW-ready. A practical guide to improve weld quality, durability and production efficiency.

Friction Stir Welding for dummies

A beginner-friendly guide to FSW fundamentals: basics, tools, materials and applications. Perfect for those new to this innovative technology.

5 essential steps to master Friction Stir Welding

Learn the 5 key steps to successfully implement FSW, from needs assessment to certification. Includes expert tips and practical examples.

Interested in finding out more?

Contact our experts in FSW technology.