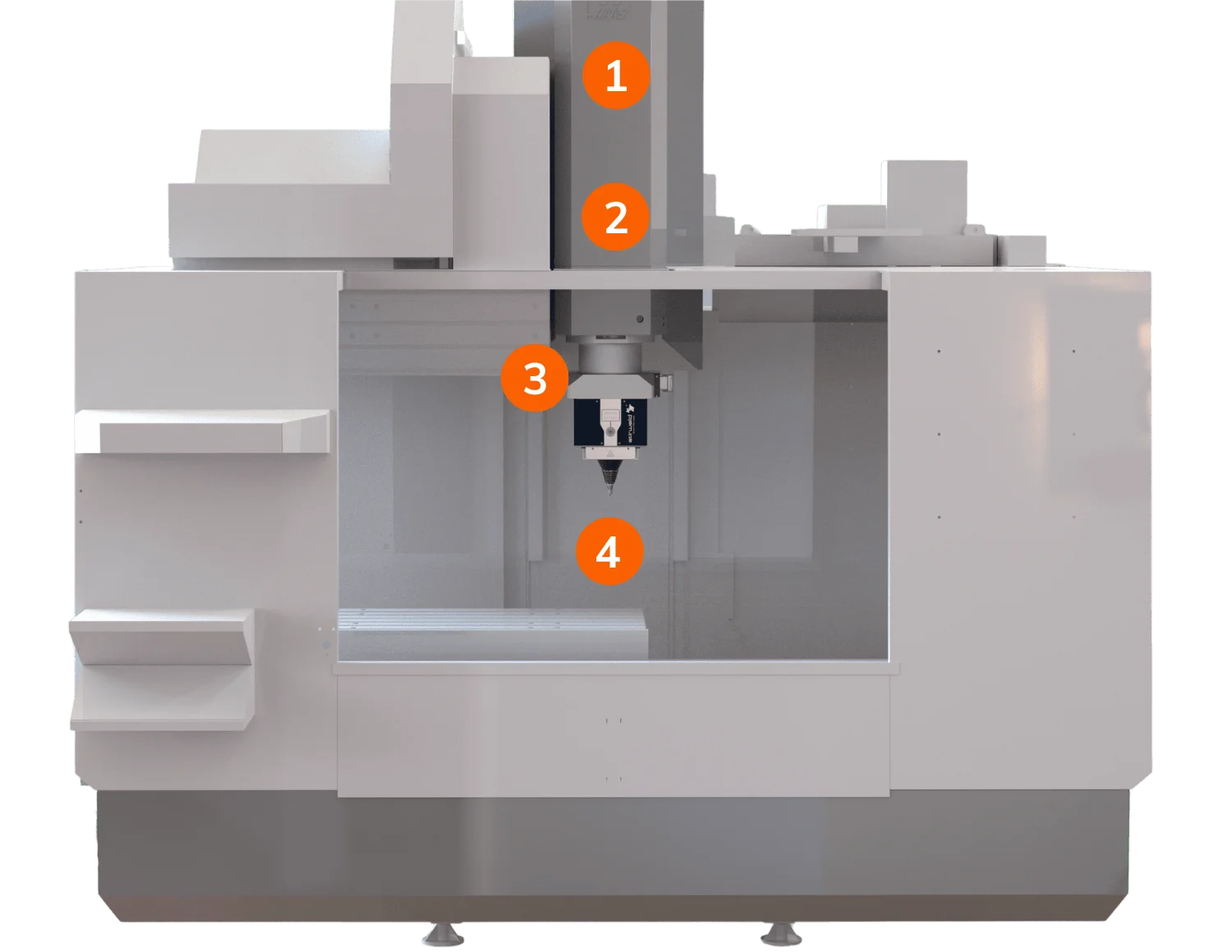

STIRWELD FSW EQUIPMENT

Smart FSW head

for CNC

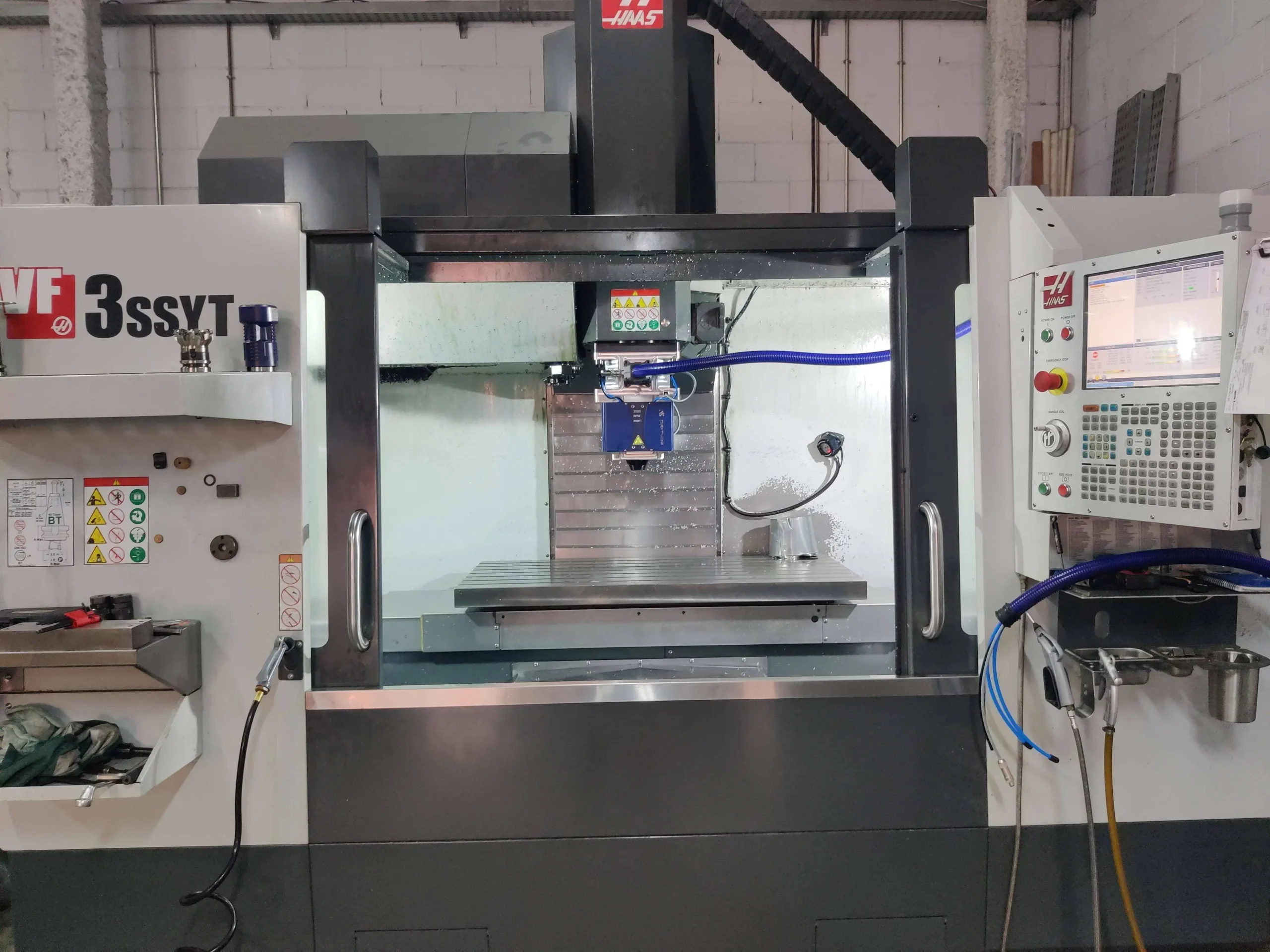

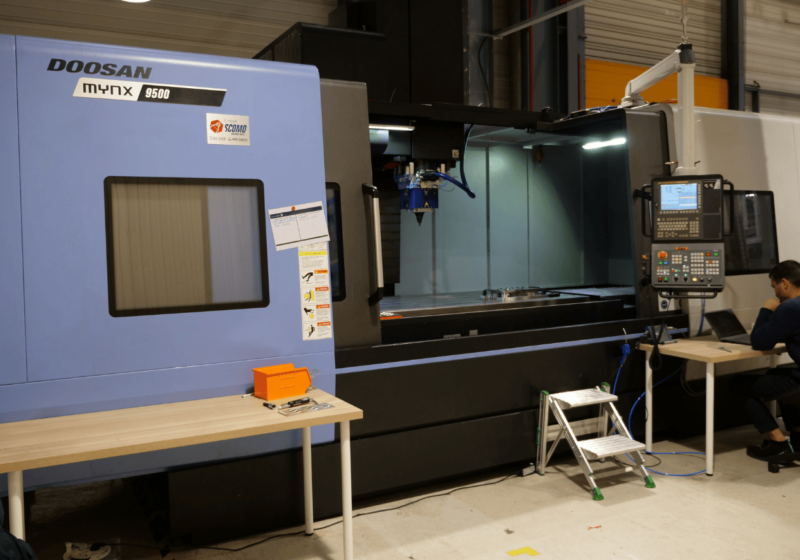

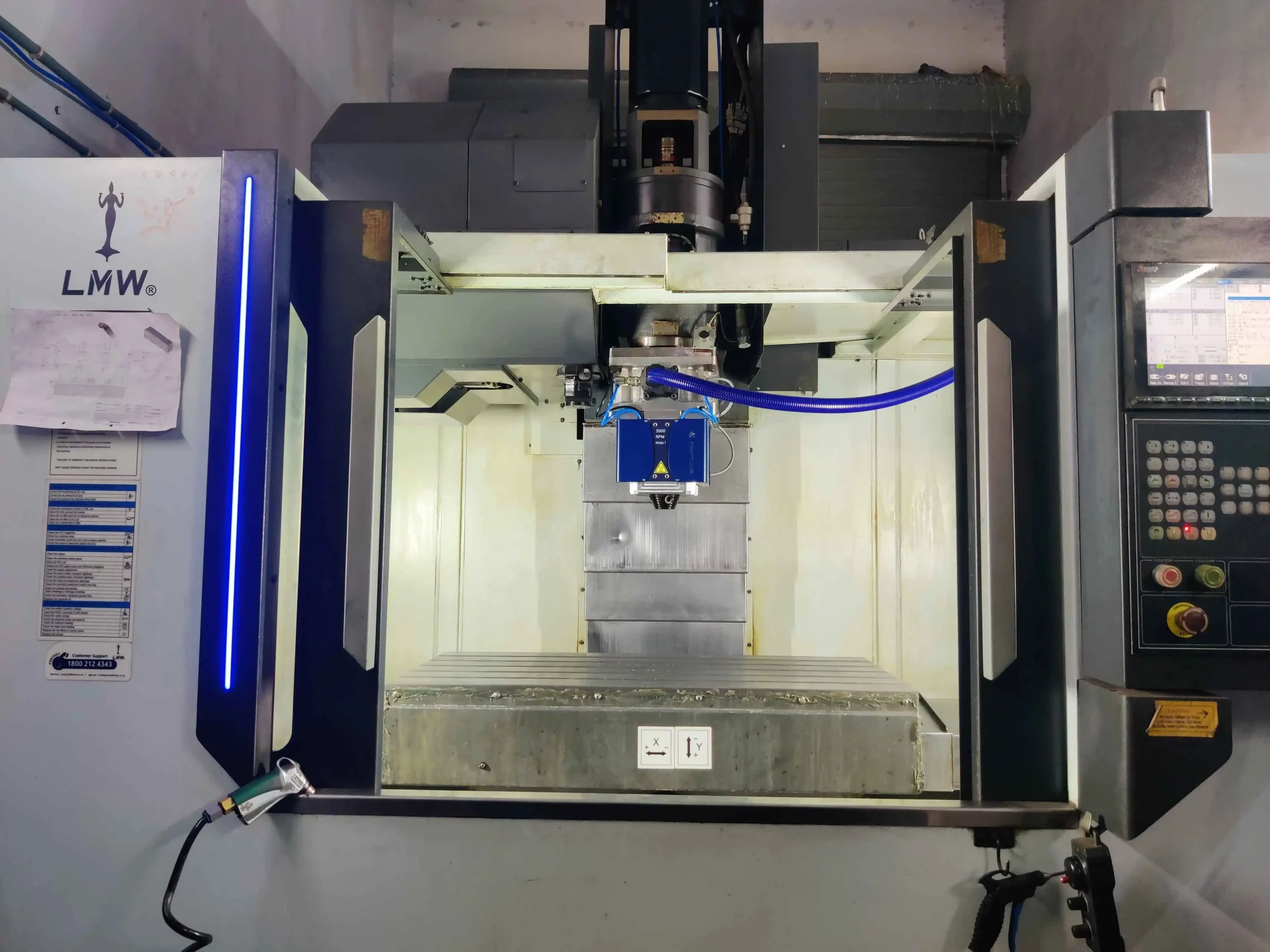

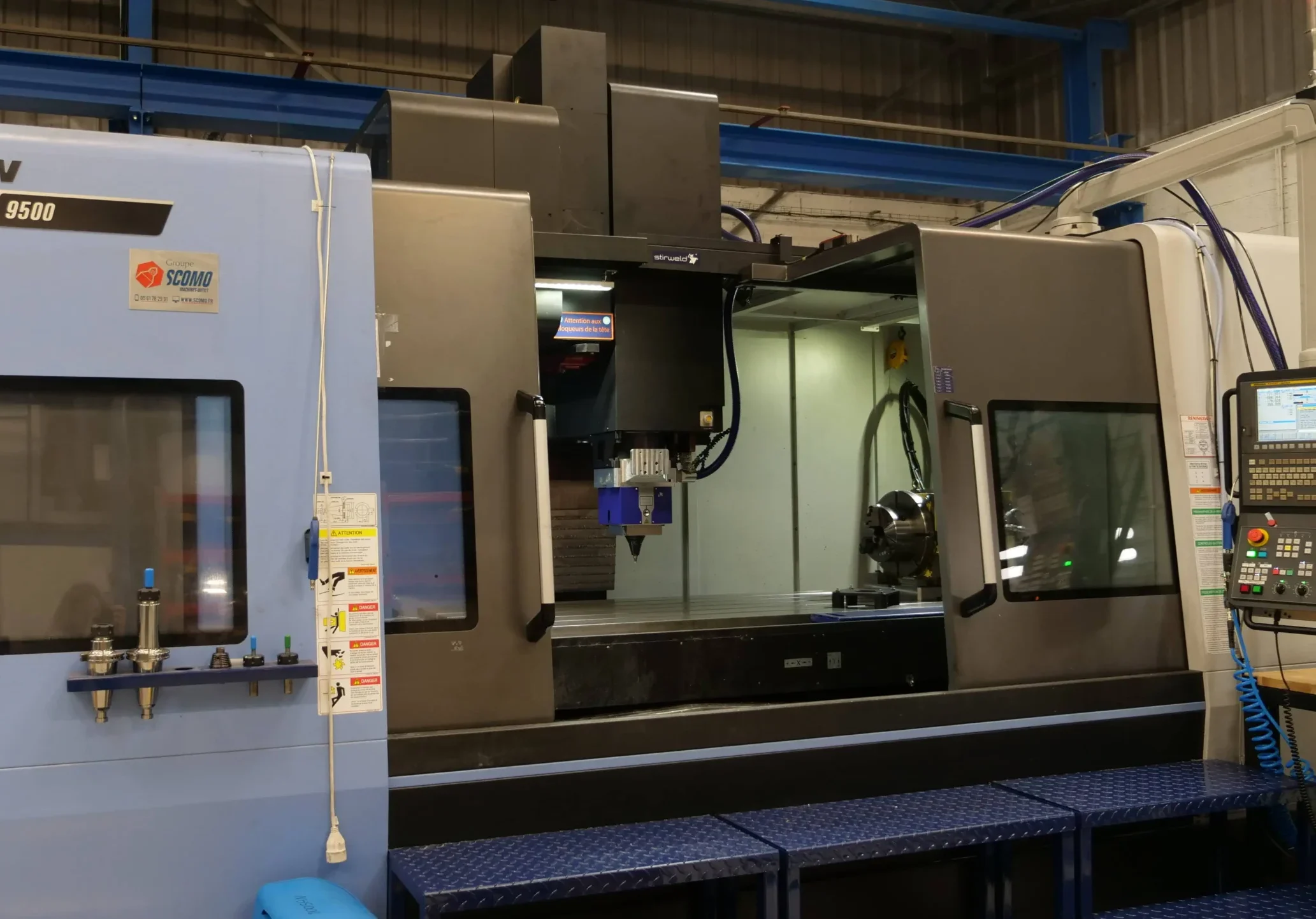

The Smart FSW Head from Stirweld, tailored for machining centers, represents an Industry 4.0 breakthrough, blending friction stir welding technology with data analytics.

Why Equip Your CNC Machine with the Smart FSW Head?

Enhanced Productivity

Elevate your welding speed to new heights with the Smart FSW Head, capable of achieving up to 3m/min thanks to its 5000 rpm performance. This significant enhancement in speed leads to greater productivity and efficiency in your operations.

Integrated Communication

The Smart FSW Head can interface seamlessly with your internal information systems, OPC UA or ERP. Designed with an open-source Beckhoff base, it facilitates smooth communication between industrial machines, enhancing efficiency and connectivity.

Real-Time Quality Monitoring

With our advanced HMI, gain immediate access to a wealth of quality control data. This system enables real-time monitoring of temperature and torque, ensuring precision and reliability in every weld. Streamline your quality assurance process with our integrated solution.

Dedicated Assistance

Your success is our priority. Benefit from expert FSW support from setup to long after, ensuring seamless operation. Count on our dedicated team for ongoing, expert guidance and solutions tailored to your specific challenges.

Unlocking Friction Stir Welding: Key Features of the Smart FSW Head

Very accurate force control

Ensuring weld integrity through consistent tool penetration, our Smart FSW Head offers precise force regulation tailored for each application. With rapid response times, it allows for fine-tuning of welding parameters for superior results.

FSW welding temperature measurement

Boost welding quality via real-time temperature monitoring, ensuring control and consistency. Our system features dual FSW tool temperature measurements with +/- 2°C accuracy, using a full wire system for reliable data without radio, Wi-Fi or Bluetooth. Enables precise FSW parameter optimization.

FSW forces and vibrations protection

Equipped with four protections: against FSW vibrations, load, welding temperature and excessive force, ensuring the CNC machine spindle remains unaffected by FSW challenges. This setup offers complete spindle protection for enhanced durability.

Cooling system

Features on-demand compressed air cooling and a water circuit within the head, coupled with a chiller, for efficient temperature management. This dual approach ensures optimal performance and longevity of the Smart FSW head.

FSW rotational speed

Delivers rotational speeds up to 6000 RPM, enabling both clockwise and counterclockwise rotation. Enhanced weld quality and parameter optimization through precise RPM monitoring.

Smart data recording

Captures comprehensive process data including welding force, speed, and FSW temperature, alongside system data like head temperature monitoring and maintenance timers. This smart recording enhances operational insights and predictive maintenance planning.

Warning pop-up

Designed by FSW experts, it features two critical thresholds for enhanced safety: vigilance for deviations beyond standard ranges, and issue detection outside safe boundaries. Fully CE certified, meeting European standards for safety, ergonomics and environmental care.

Technical Specifications of the Smart FSW Head

Introducing the Smart FSW Head, a cutting-edge solution meticulously crafted by leading experts in Friction Stir Welding and machining. Patented in 2015 by SATT, a renowned French governmental organization, this innovative tool represents the pinnacle of FSW technology, combining advanced features with user-friendly design to meet the high standards of modern manufacturing environments.

| Welding speed | Up to 3m/min |

| Rotational speed (welding and milling) | 6000 RPM |

| Maximum operational payload | 25 kN |

| Cooling system | Intelligent air and water cooling for optimized consumption and tailored usage |

| Human-Machine Interface (HMI) | Sophisticated, user-friendly design |

| Forging force display | Live display for easy welding parameter adjustments |

| Radius force application (X and Y directions) | Up to 5 kN |

| Stiffness | Extreme stiffness (no lateral deviation of the FSW tool) |

| Smart tool holder | Equipped with temperature sensing |

The Human-Machine Interface (HMI) of the Smart FSW Head introduces enhanced control and connectivity for welding operations:

Equipped to handle the demands of modern manufacturing, the HMI empowers operators with data and controls necessary for fine-tuning welding processes, ensuring every weld meets high standards of quality.

Advanced Options of Our Smart FSW Head

FSW Torque Measurement

This feature stands as a cornerstone for ensuring the safety and integrity of your friction stir welding processes. The FSW Torque Measurement option provides real-time insights into the torque exerted by the welding tool, a critical parameter that directly influences the quality and consistency of your welds. By enabling the detection of potential deviations in tool performance, this option ensures that your welding operations maintain the highest standards of safety and quality, allowing for immediate adjustments and optimization of the welding parameters.

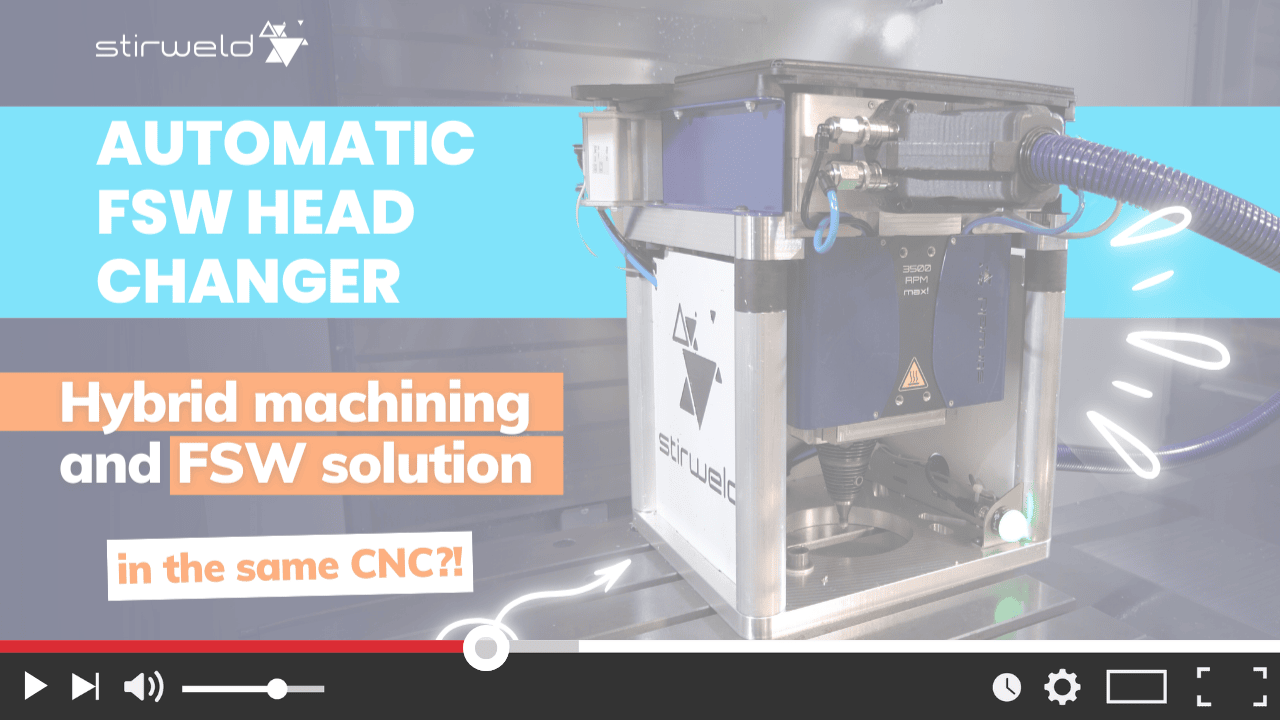

Automatic Head Changer

Transform your CNC machine into a fully automated, 4.0 compliant powerhouse with our Automatic Head Changer. This cutting-edge system combines 100% automatic welding with the flexibility of hybrid equipment, offering both welding and milling capabilities within a single machine. This dual-functionality enables full access to your entire carousel tool changer, optimizing your time cycle without the need for maintenance. Designed to minimize its footprint on the CNC table with dimensions of 300 mm by 300 mm, it maximizes workspace efficiency. Capable of achieving welding speeds up to 3m/min, this universal system adapts effortlessly to any CNC machine, marking a leap in operational flexibility and efficiency.

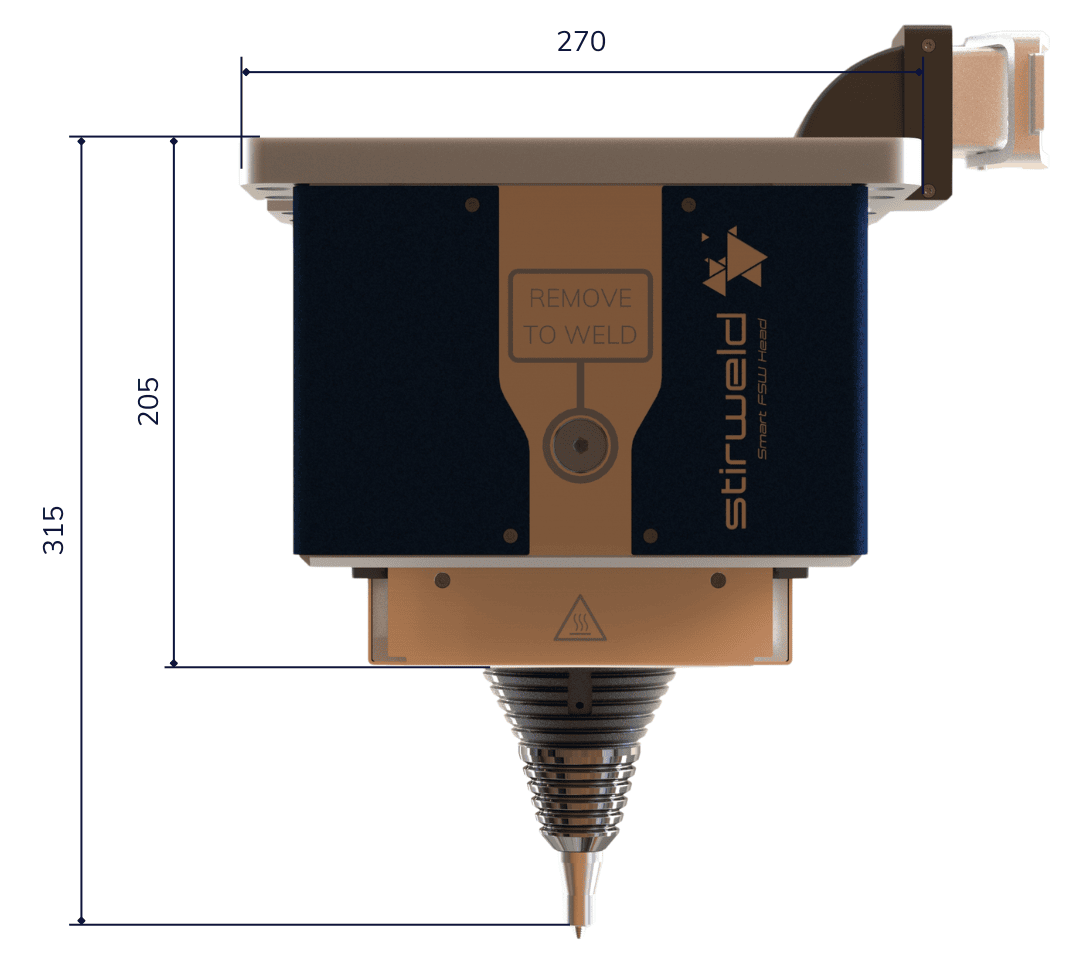

Dimensions and Machine Footprint of our Smart FSW Head

Smart FSW head dimensions

Tailoring the fit of the FSW head to your machinery is a key step for optimal functionality. The Smart FSW Head has been engineered with exact dimensions to ensure it integrates flawlessly with various CNC machines. Below are the specifications crafted for peak performance and seamless machine compatibility:

| Compact stature | Standing at a height of 315 mm, it offers a space-efficient design without compromising functionality. |

| Lightweight build | Weighing in at 35 kg, this head is designed for easy handling and installation. |

| Efficient cooling system | Utilizes a water cooling flow rate of 5 l/min at 25°C, ensuring stable operating temperatures. |

| Robust air cooling | Operates at a consistent pressure of 3 bar, providing reliable cooling during intensive welding tasks. |

| Flexible control | Features a control interface range extending up to 10 m, with options available for further reach. |

Rough estimates for integrating the Smart FSW Head into a machining center

When considering the integration of the Smart FSW Head into your machining center, here are some ballpark figures to guide you:

Spindle power: Aim for a minimum spindle power capacity of 10 kW to operate the Smart FSW Head efficiently.

Torque specification: A spindle torque of 50 N.m at 1000 RPM is recommended for optimal performance.

Attachment size: Common attachment sizes such as ISO 40, BT 40, or HSK 63 are generally compatible, offering flexible mounting options.

Space requirement: Allow for a minimum clearance of 350 mm below the spindle nozzle to accommodate the 315 mm height of the Smart FSW Head.

Keep in mind that while these specifications serve as a general guide, variations are possible due to the unique configurations of CNC machines. If there’s any uncertainty about the integration, or if your setup has specific requirements, we encourage you to contact us. Our team is adept at ensuring compatibility and with the Smart FSW Head’s design, successful installation is possible in 99% of CNC machines available in the market. We’re here to address any questions promptly and assist you in optimizing your CNC setup with our Smart FSW Head.

Frequently Asked Questions

Find quick answers to your questions with our FAQ. This section covers a range of common inquiries, providing you with immediate solutions and detailed information.

The welding temperature with the FSW head is managed according to 3 parameters:

- the feed speed: the faster the FSW tool feeds, the colder the material will be

- the rotation speed: the faster the tool rotates, the hotter the material will be

- Z-force (which refers to the force exerted vertically during the welding operation): the more the FSW head presses on the parts to be joined, the hotter the parts will be.

It is important to control these 3 parameters to ensure a good and strong FSW weld.

To get an indication of the temperature during your welding operations, you can use Stirweld’s temperature measurement system.

Yes, Stirweld’s FSW welding head is a hybrid system that allows machining and welding.

The FSW head fits all machine tools and is easily installed for an optimized friction stir welding operation. The user can quickly mount and dismount the FSW tool to switch from welding to machining and vice versa. Stirweld’s Automatic Head Changer is a time-saving device: the 2 operations can be performed on the same CNC.

While our technical specialists review your inquiry, explore our detailed FAQ section covering Smart FSW head for CNC applications. This comprehensive resource provides troubleshooting guides, integration tips, and continuously updated solutions to help you maximize your CNC-mounted friction stir welding head performance and streamline your automated welding processes.

Transform Your Operations with Smart FSW Technology

Embrace the next level of FSW with the Smart FSW Head. Boost your operation’s speed, enjoy seamless system integration and rely on precise, real-time monitoring for unmatched welding performance.