WHERE FSW TECHNOLOGY MAKES A DIFFERENCE

Friction Stir Welding in Railway

FSW technology is transforming the railway industry with its lightweight, high-quality and cost-effective components.

Unlocking Railway Potential with Advanced FSW Techniques

Railway industries worldwide are seeking modernization, sustainability, and safety enhancements for aging infrastructures and equipment. The Friction Stir Welding technique offers eco-friendly, cost-effective solutions, ensuring high-quality joints and broad material adaptability, meeting these challenges effectively.

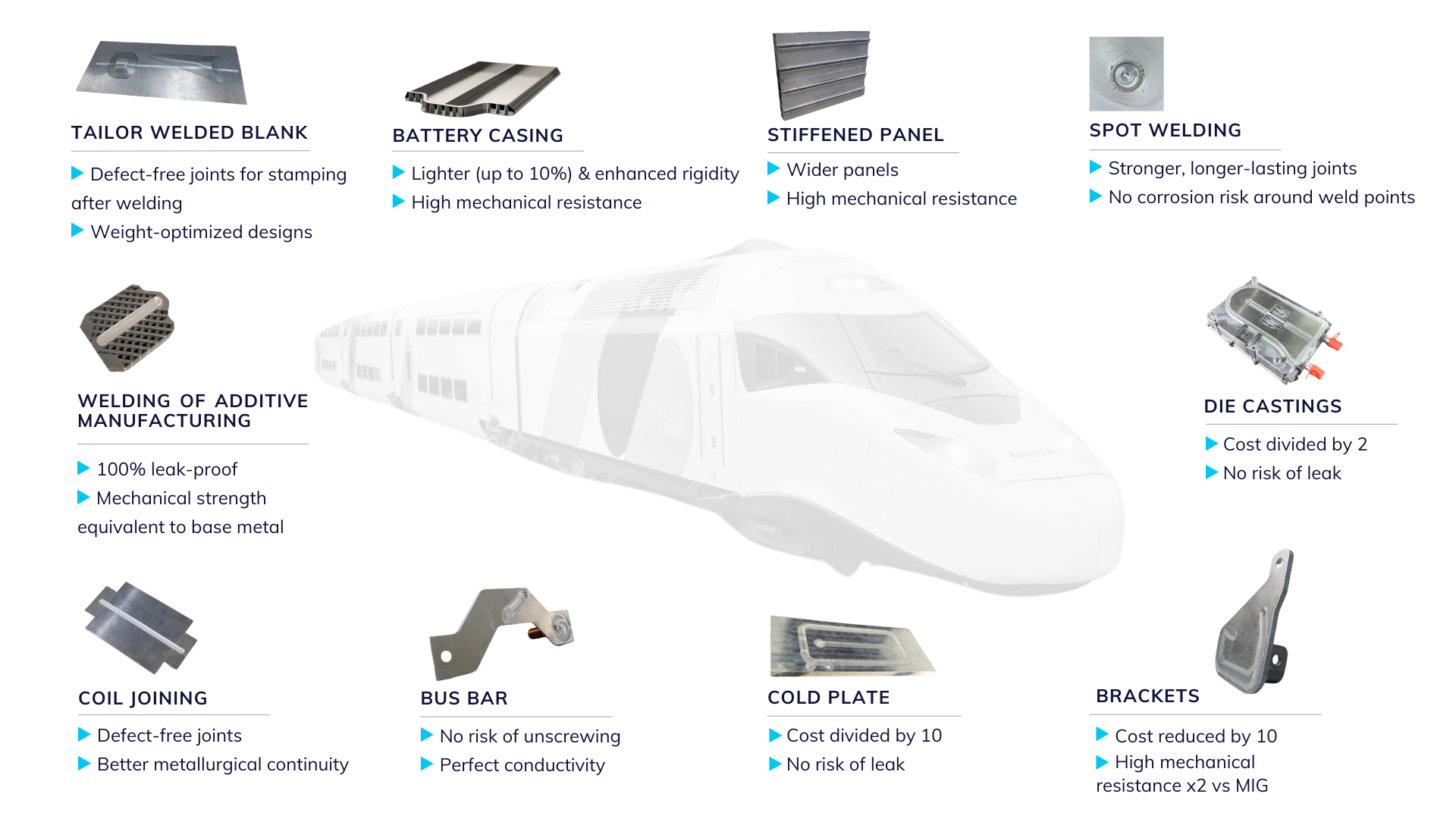

Exploring FSW Applications in the Railway Sector

In the critical railway sector, safety, fatigue resistance, adaptability to climate changes and corrosion resistance, coupled with superior component quality, are indispensable. Friction Stir Welding addresses these demands by enabling the welding of various railway components.

Stiffened panels

Employed in train floors and side structures, stiffened panels benefit from FSW, a prevalent welding technique for these vital railway elements.

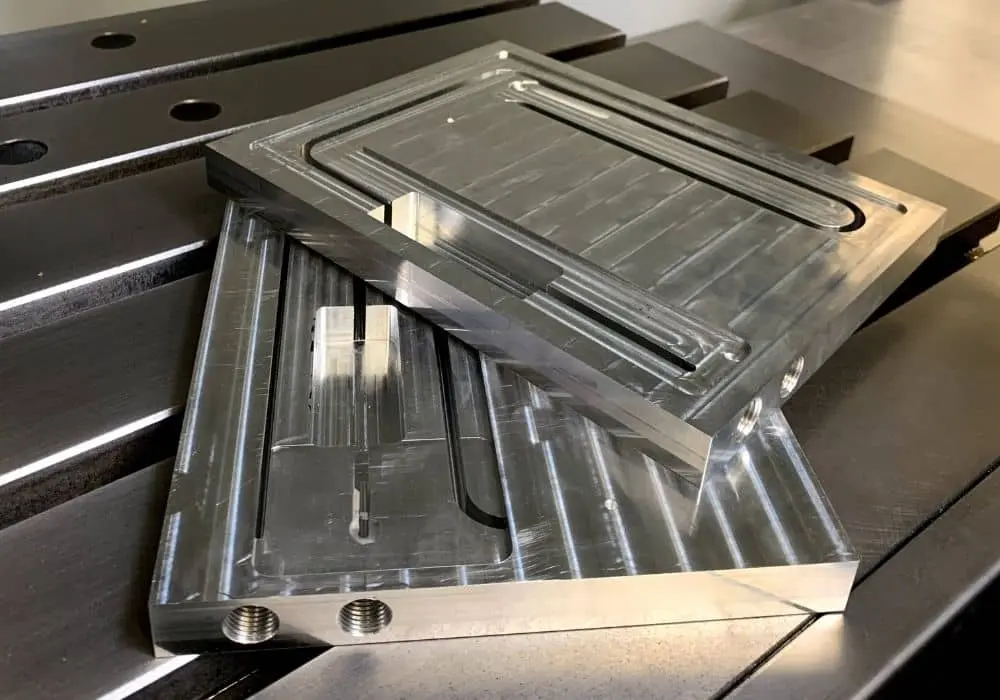

Cold plates

Essential for managing the thermal aspects of railway equipment’s electric components, liquid cold plates ensure the peak performance and longevity of advanced systems.

Bus bars

Friction Stir Welded busbars ensure robust electrical connections for trains, offering high reliability with low maintenance in harsh operating conditions.

Recommended FSW Equipment for Railway Applications

Our FSW equipments deliver a range of benefits in terms of quality, cost and environmental impact, meeting the rigorous requirements of the railway sector. Dive into the equipment our experts particularly recommend for your unique requirements.

Standard FSW head for CNC

Designed for versatility, our Standard FSW head is compatible with 3, 4 or 5 axis machines, immediately offering precise force control, live force monitoring, effective tool cooling, and enhanced protection against mechanical stresses and vibrations — all crucial for top-notch FSW welding.

FSW spindle for robot

Tailored for high payload robots, this FSW solution provides conventional industrial robots with friction stir welding capabilities. This transforms them into multifunctional tools that merge welding and machining functions, complete with automated tool-switching capabilities.

Dive Deeper: Comprehensive FSW Railway Applications Resources

Eager to explore FSW Railway Applications further? We’ve compiled a selection of valuable resources tailored for you, featuring engaging webinars, informative articles, and comprehensive whitepapers. Dive in by clicking below to discover the repository of knowledge we’ve prepared for you.

Webinar – 45 min – Replay on demand

Stiffened panels welded by FSW

Explore the replay of our webinar! Dive deep into innovative techniques for assembling stiffened panels through friction stir welding. The session covers the distinct attributes of 6xxx alloys and the intricacies of high strength 2xxx and 7xxx aluminum alloys. Gain insights from industry experts, making this a must-watch whether you’re a seasoned professional or just keen on broadening your knowledge.

Blog articles – 5 min

Overcoming cold plate manufacturing challenges

Stiffened panels assambled by friction stir welding

White paper – 20 min

Thermal management – FSW liquid cold plate

Discover the prowess of FSW in fabricating liquid cold plates within our enlightening white paper. Transform manufacturing obstacles into prospects by tackling essential concerns with this resource.

White paper – 20 min

Aluminium stiffened panels welded by FSW

Explore the unmatched ease of assembling stiffened aluminium panels with FSW in our concise white paper. Transform assembly challenges with techniques ensuring durability and resistance.

On Track with FSW Technology?

Delve deeper into how Friction Stir Welding can reshape rail manufacturing and maintenance. If you’re seeking innovative solutions or have questions about FSW in the rail sector, we’re here to guide you.