WHERE FSW TECHNOLOGY MAKES A DIFFERENCE

Friction Stir Welding in Automotive

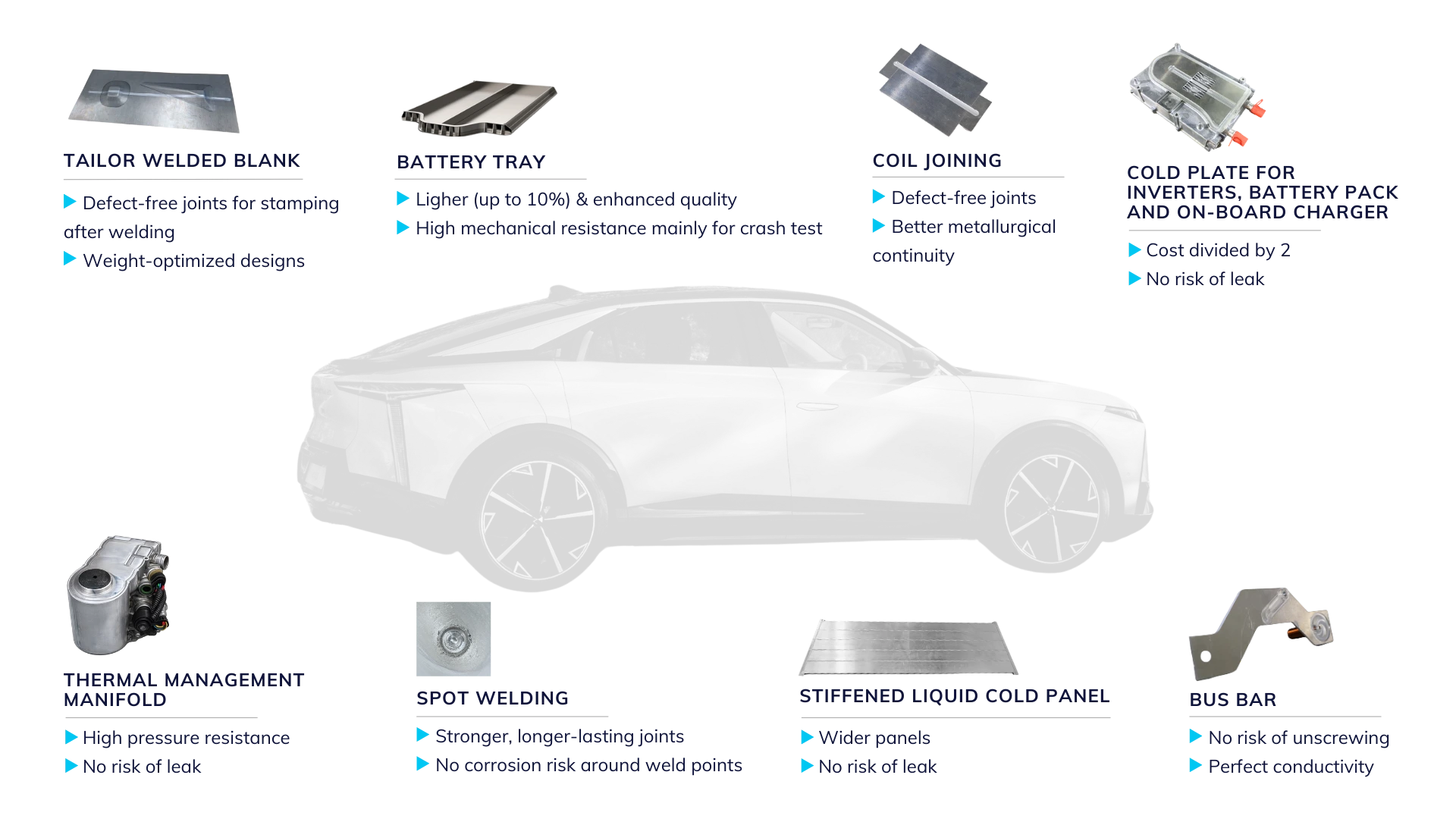

FSW technology revolutionizes automotive manufacturing with high-quality, lightweight and cost-effective components.

Unlocking Automotive Potential with Advanced FSW Techniques

The automotive industry faces challenges like the urgent transition to electric vehicles, adapting to new consumption models and managing global crises’ impacts. Friction Stir Welding contributes significantly by enabling efficient welding for lightweight EVs, supporting rapid mass production for various mobility services and offering reliable solutions during economic uncertainties. With advantages like high-quality welds, waste reduction and cost-effective production, FSW helps address issues related to competition, sustainability, regulations and standards in the industry.

Exploring FSW Applications in the Automotive Sector

FSW is crucial for e-mobility applications, delivering high-quality welds that support the development of lightweight, efficient and eco-friendly vehicles, while enhancing rapid and cost-effective mass production to meet contemporary industrial and environmental challenges.

Bus bars

Busbars assembled using Friction Stir Welding are favored in the automotive industry for their robust and reliable electrical conductivity, crucial for enhancing vehicle performance.

Heat sinks

Aluminum die-cast heat sinks are indispensable for the thermal management of electric and hybrid vehicles, guaranteeing the optimal performance and extended lifespan of high-performance systems.

Battery trays

Battery trays, crucial for housing and protecting electric vehicle batteries, must meet various constraints and quality standards, a challenge eased by the use of FSW combined with extrusions.

Recommended FSW Equipment for Automotive Applications

Our FSW equipment provides a multitude of advantages regarding quality, cost, and environmental impact, adhering to the strict demands of the automotive sector. Explore the Stirweld FSW equipments that our specialists highly endorse for your specific needs.

Standard FSW head for CNC

Engineered for broad compatibility, the FSW standard head-V3 seamlessly works with existing 3, 4, or 5 axis machines, immediately providing accurate force control, real-time force monitoring, efficient tool cooling, and superior protection against mechanical stress and vibrations, all essential for producing high-quality FSW welding.

FSW spindle for robot

Compatible with high payload robots, the robotic FSW solution, utilizing our FSW spindle, imparts Friction Stir Welding functions to standard industrial robots, turning them into hybrid tools that combine welding and machining capabilities with automatic tool changing features.

They Trust Us

“FSW technology has the possibility that, when you weld, you don’t degrade the material as other process or other joining technologies. The main advantage that we see at Stirweld is the intercompability and the flexibility that the head provides us compared with a dedicated machine.”

Mario Alberto Solís Alvarez

R&D Innovation Engineer

Dive Deeper: Comprehensive FSW Automotive Applications Resources

Interested in delving deeper into FSW Automotive Applications? We offer a range of resources for your convenience, including insightful webinars, articles, and in-depth whitepapers. Click below to access a trove of information we’ve assembled for you.

Webinar – 45 min – Replay on demand

FSW die casting heat sinks for e-mobility

Unlock the secrets of enhancing quality while reducing production costs in e-mobility. Register for our free technical webinar on die casting heat sinks and discover the transformative power of FSW technology in your operations. Elevate your knowledge and gain a competitive edge!

Blog articles – 5 min

FSW die casting heat sinks for e-mobility

Stiffened panels assembled by Friction Stir Welding

White paper – 20 min

FSW water heat sink for e-mobility

Electric and Hybrid Vehicle manufacturers seek affordable, compact and efficient heat transfer solutions, with heat sinks emerging as the optimal choice. This report elucidates market trends, cost-effective and quality assembly of heat sinks with FSW design.

White paper – 20 min

Aluminium stiffened panels welded by FSW

Dive deeply into the unparalleled simplicity of joining stiffened aluminum panels through Friction Stir Welding in our in-depth white paper. Overcome assembly hurdles with a method that assure lasting strength and resilience.

Drive Innovation with Friction Stir Welding!

Whether you’re looking to enhance parts assembly, have an ongoing automotive project, or just curious about how Friction Stir Welding can revolutionize car manufacturing, our team is at your service. Get in touch today!