STIRWELD FSW EQUIPMENT

Friction Stir Welding Technology Equipment

At Stirweld, we make Friction Stir Welding (FSW) accessible to all manufacturers. Our equipment adapts to your existing CNC or robotic setup, helping you achieve stronger, cleaner and more reliable welds — while saving time and reducing costs.

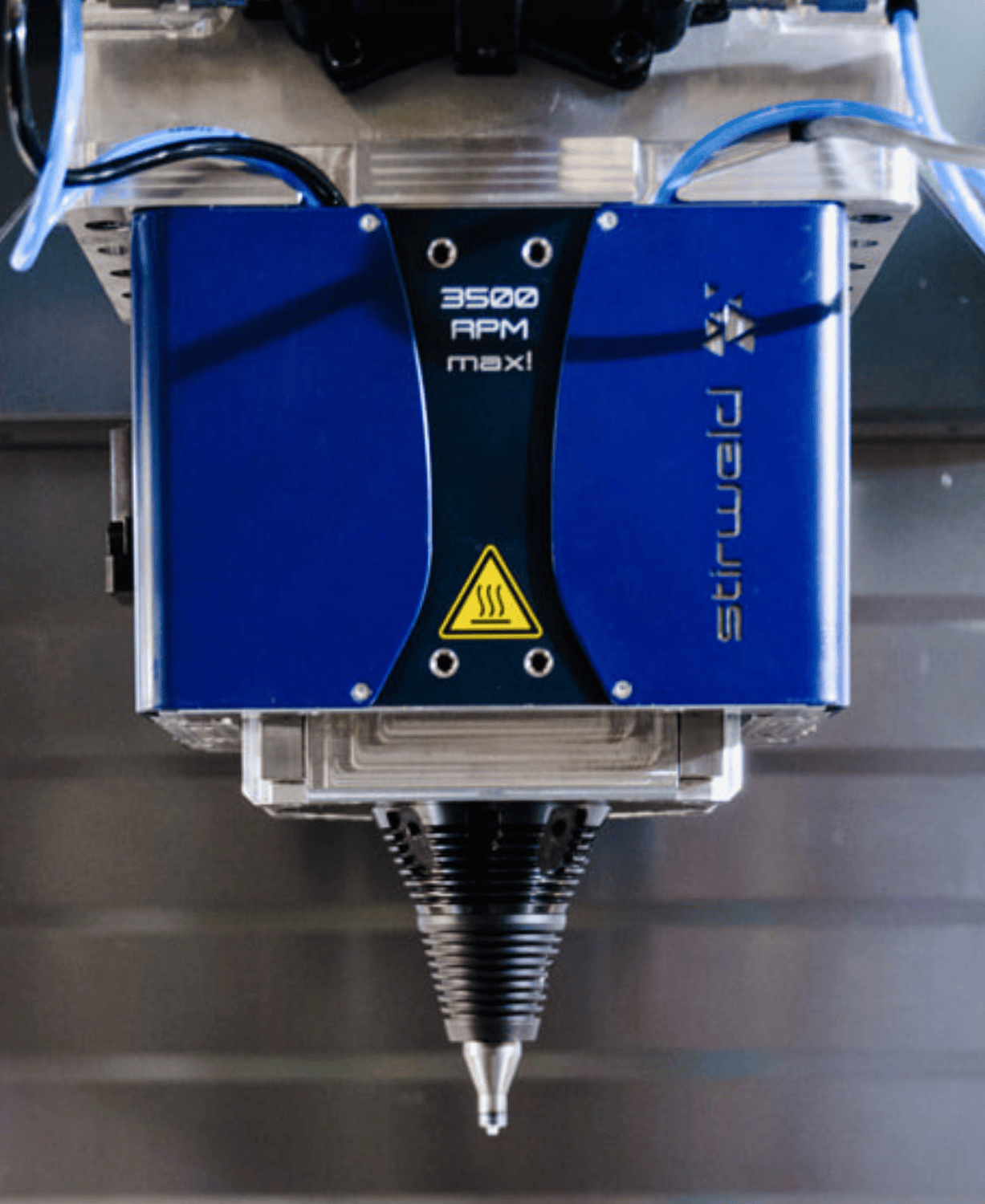

FSW Machines: Heads for CNC and Robotic Spindles

Retrofitting your CNC or robot with FSW has never been easier. Stirweld offers advanced heads designed to integrate seamlessly with both standard machining centers and robotic spindles, unlocking the full potential of your production line. Our FSW heads allow you to weld a wide variety of materials and geometries with superior mechanical strength and zero porosity. By eliminating the need for costly dedicated machines, Stirweld ensures a cost-effective path to innovation, enabling rapid prototyping, small-series manufacturing and large-scale production. With our robust technology, you benefit from greater flexibility, reduced cycle times and improved product performance.

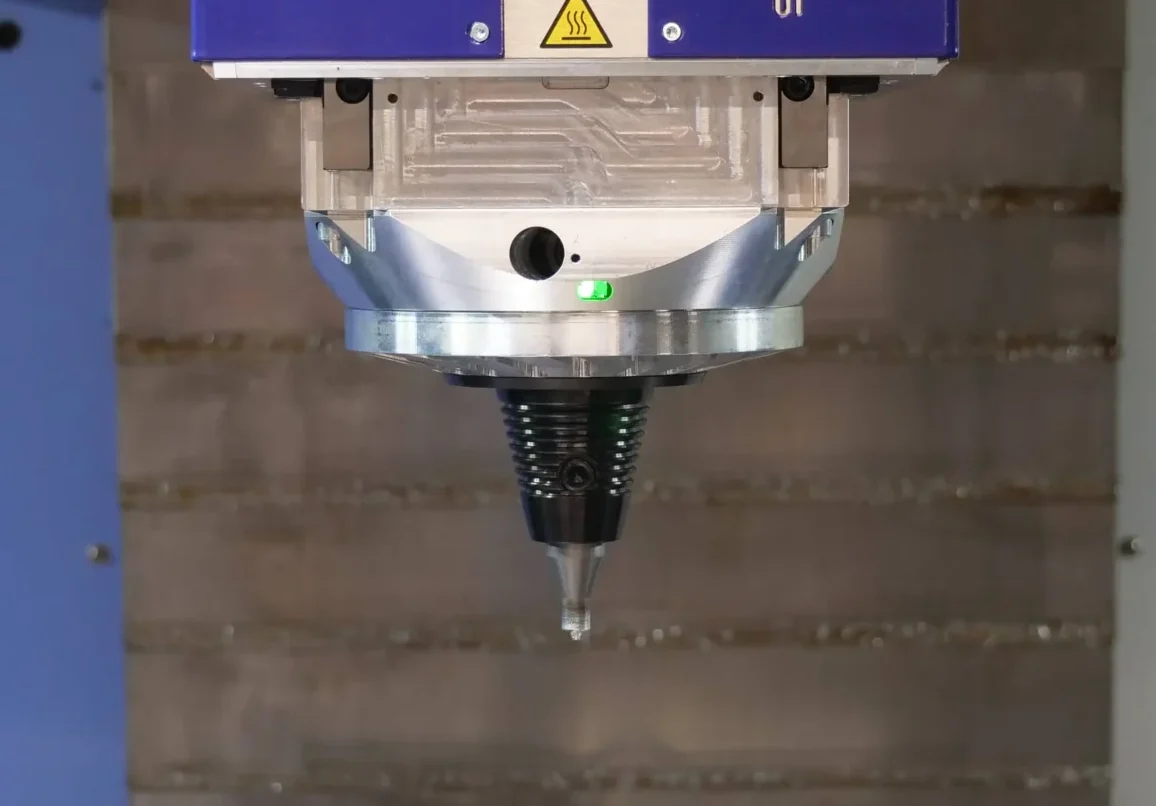

Standard FSW Head for CNC

For cost-effective Friction Stir Welding integration.

Smart FSW Head for CNC

Advanced monitoring & welding automation.

FSW Head with Retractable Pin

Ideal for keyhole-free welding on complex parts.

FSW Spindle for Robot

Designed for robotic arms in automated cells.

Not sure which FSW solution fits your needs?

Our free Selection Guide shows you the key criteria and equipment options so you can identify the FSW solution that truly fits your needs — helping you boost performance, reduce costs and accelerate production.

FSW Tools: Adapted yo Your Applications

No matter what you’re welding — aluminum alloys, copper, or dissimilar materials — choosing the right tool makes all the difference. Stirweld’s FSW tools are designed to adapt to different materials, thicknesses and joint configurations, ensuring durability, versatility and defect-free welds. With the right tool, you can optimize your process, reduce costs and achieve reliable results every time.

Looking for more details?

Get technical specifications and a complete overview in our FSW Tools Catalogue.

Aluminium Welding Tools

For strong, precise welds on aluminium alloys.

Aluminium to Steel Welding Tools

Specially designed for dissimilar joints — no cracks, no compromises.

Cast Aluminium Welding Tools

Tackle casting defects with tools made to handle porosity and variability.

Copper Welding Tools

Built for precision welding on high-conductivity materials like copper.

They Trust Us

Companies of all sizes trust Stirweld to integrate Friction Stir Welding into their production. Here are just a few examples. Discover their experience in their own words:

“FSW technology has the possibility that, when you weld, you don’t degrade the material as other process or other joining technologies. The main advantage that we see at Stirweld is the intercompability and the flexibility that the head provides us compared with a dedicated machine.”

Mario A. Solís

R&D Engineer

“With Stirweld’s Friction Stir Welding technology, we achieved better sealing and shorter production lead times. This innovation opened new opportunities and enabled us to deliver more advanced solutions. We place full trust in this long-term partnership.”

Robert Glemot

CEO

“Thanks to Stirweld FSW Technology, we can weld whatever application size we want on CNC machine. FSW gives a really good static outcome without any other operations needed. With this innovative solution, we can now diversify our operations at a very low cost and very efficiently.”

John Erian

Production manager

“At Calip, we use Friction Stir Welding for three main reasons: sealing, as it provides the only reliable solution for our clients’ challenges; mechanical strength, essential for large profiles; and repeatability, which guarantees consistent quality across welds.”

Gabriel Venet

PhD, Mech. Eng.

Ready to Bring FSW to Your Production?

Discover all our solutions in detail with the Stirweld FSW Equipment Catalogue, or get in touch with our team to discuss your project directly.