FSW APPLICATION

Battery Trays Welded by FSW

Lightweight, crash-resistant aluminium battery casings with weld strength close to the base metal.

Why Choose Friction Stir Welding for Your Battery Trays Assembly?

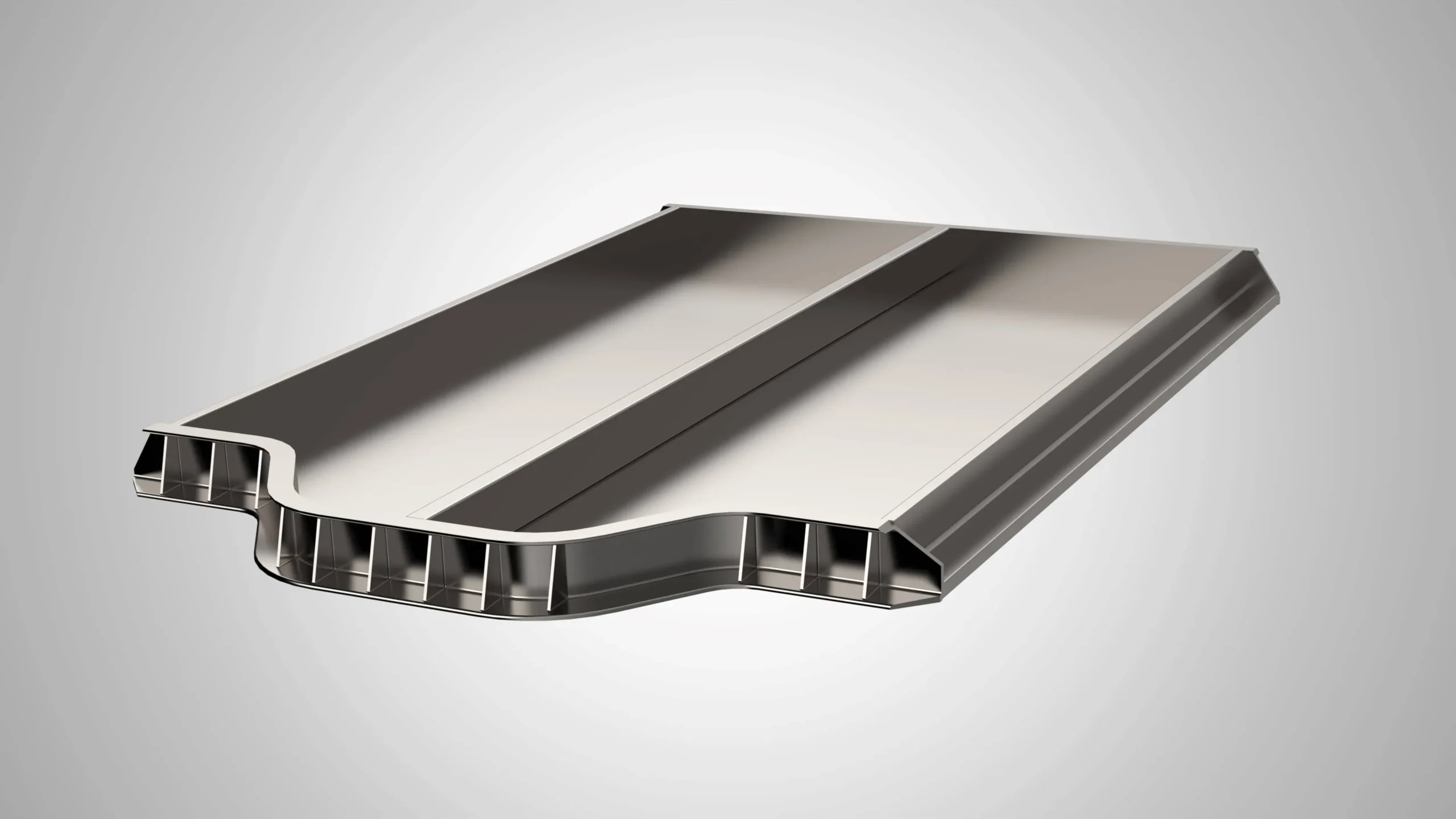

Battery trays, also referred to as battery casings, are key structural components for electric and hybrid vehicles, railways and other industrial applications. Traditionally assembled using MIG/TIG welding, these enclosures are now increasingly manufactured with Friction Stir Welding (FSW) to achieve leak-tight joints, lightweight construction and outstanding crash performance. By using FSW, manufacturers gain technical advantages that directly improve safety, durability and cost-efficiency.

High Crash Resistance

FSW weld resistance is close to the base metal, allowing the weld to accept high plastic strain before failure.

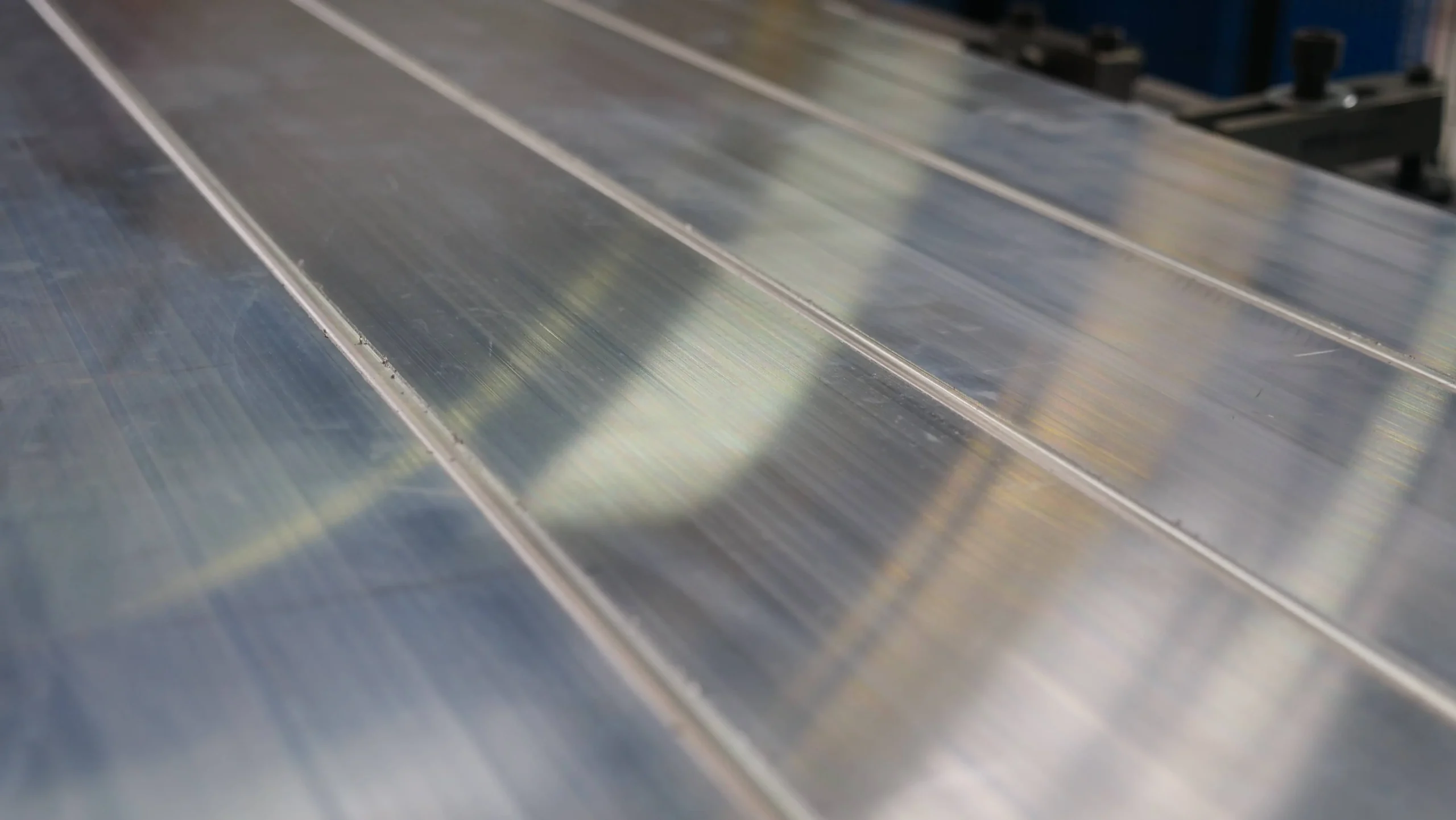

No Risk of Leak

Solid-state welding removes porosity, creating a sealed tray that protects internal components from external elements.

Full Aluminium

The battery tray is made of aluminium, resulting in a light, low-cost, fully recyclable tray with excellent heat transfer.

Superior Strength

FSW results in 2 times higher mechanical resistance compared to MIG or TIG. This results in a weight reduction of 10%.

Cost Divided by 10

FSW eliminates the need for filler material, shielding gas and extensive rework, making production far more cost-efficient.

Technical Specifications of FSW-Welded Battery Trays

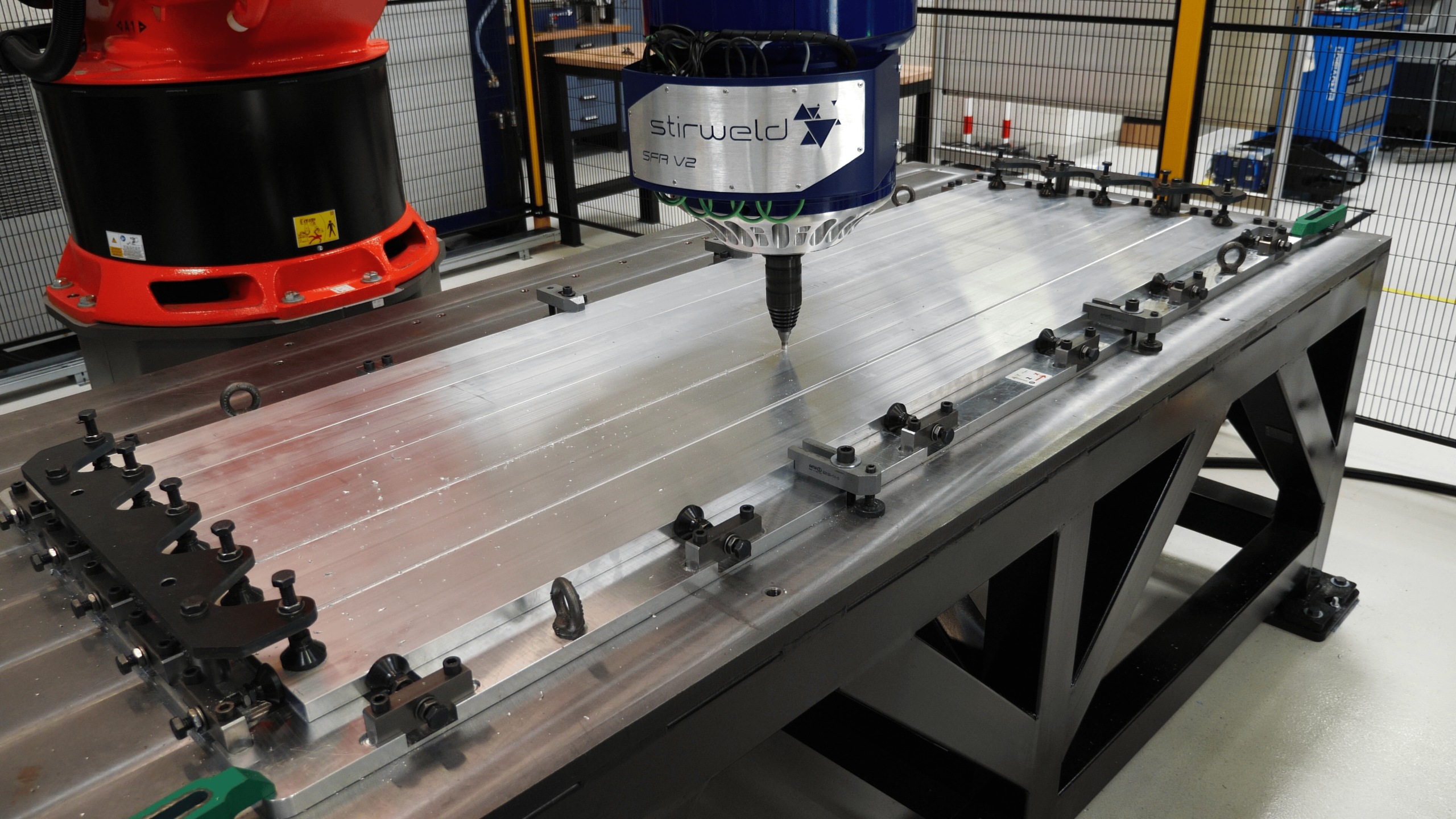

See Friction Stir Welding Applied to Battery Trays in Real-Time

Comparing FSW to Traditional Battery Trays Assembly Techniques

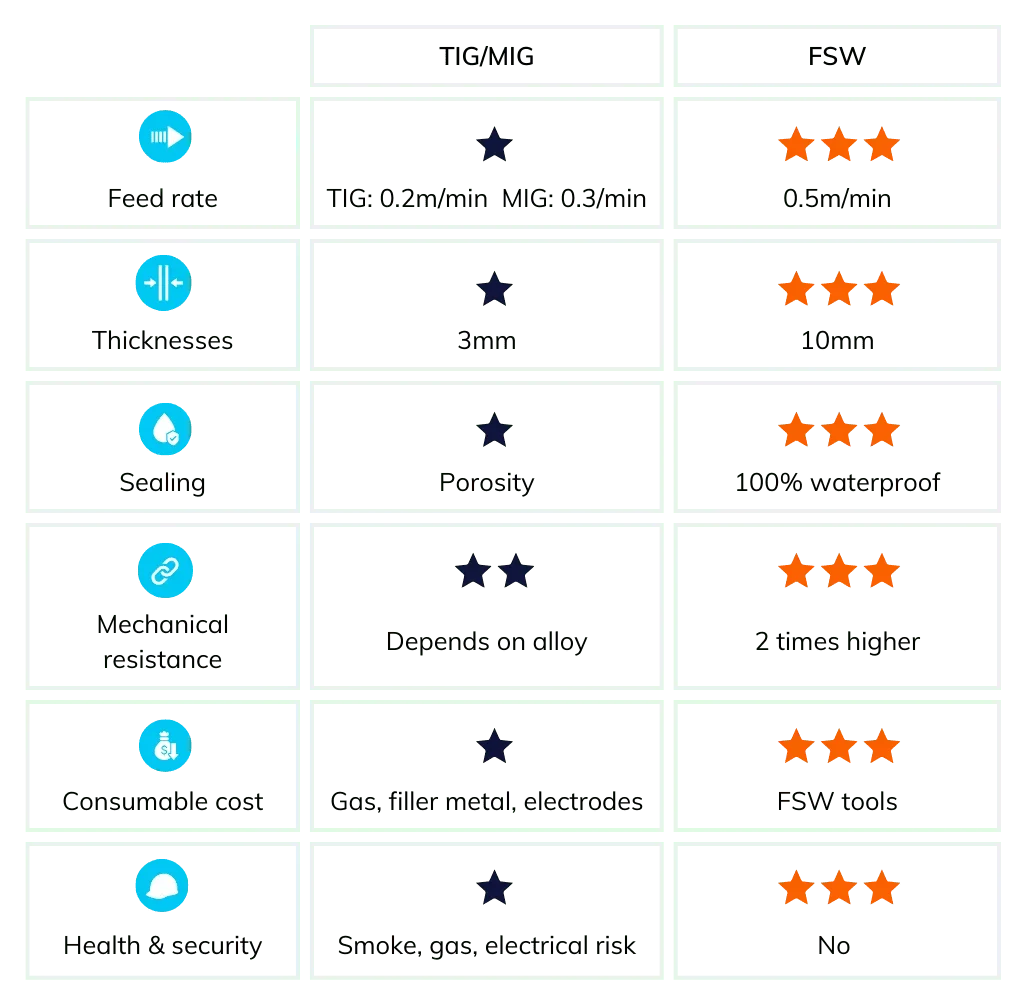

Friction Stir Welding vs. TIG and MIG

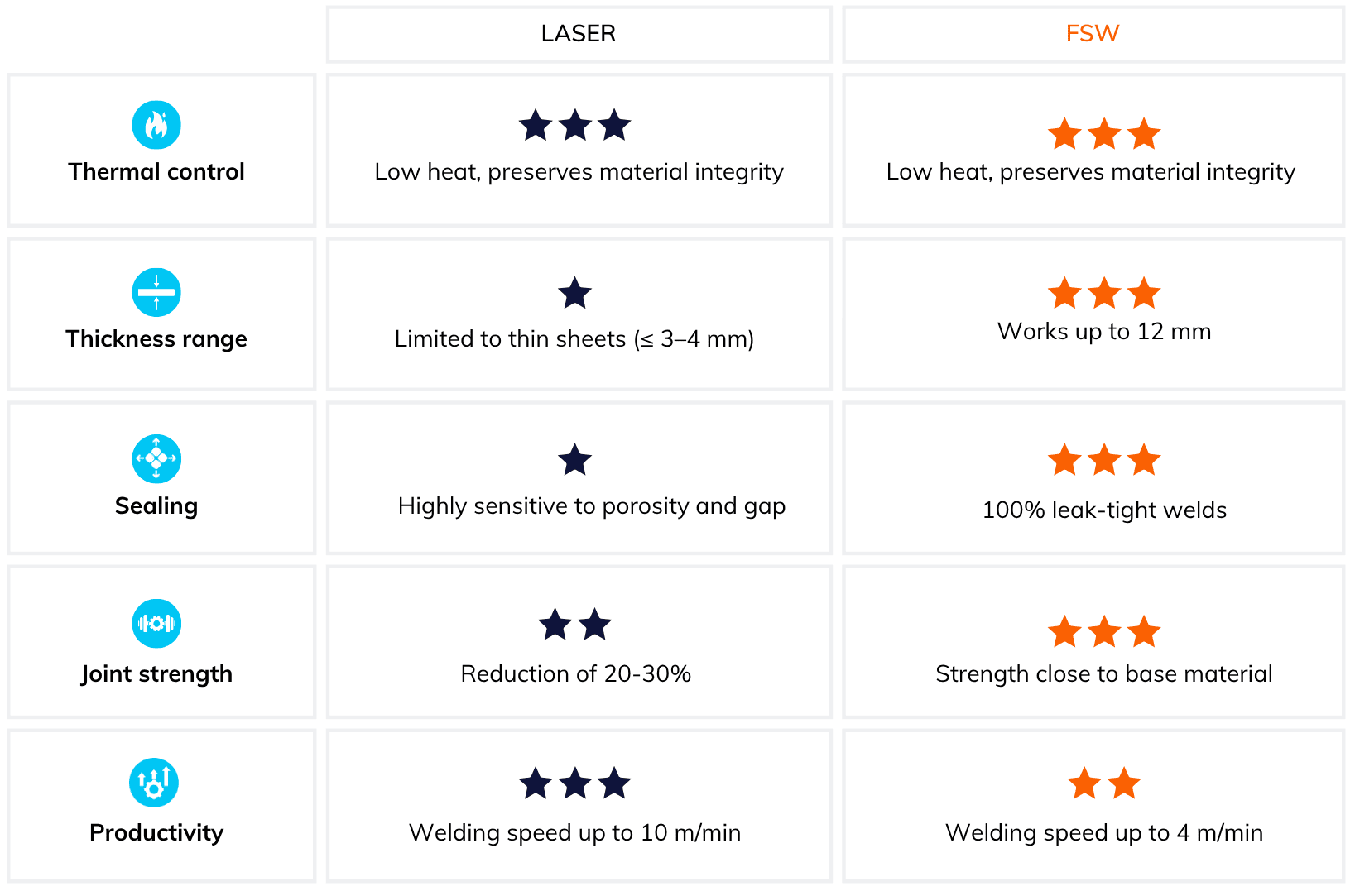

Friction Stir Welding vs. Laser

Aluminium Battery Trays: Key Concerns for Critical Sectors

Aluminium battery trays must meet strict requirements for safety, durability and thermal management. Their design and performance are especially critical in industries where reliability under heavy loads and demanding environments is non-negotiable.

Automotive

Lightweight trays for EVs ensure crash safety, long range and efficient thermal performance.

Railways

Robust casings protect batteries in trains and metros, combining durability with low maintenance.

Other e-Mobilities

From buses and trucks to construction and mining engines, aluminium battery trays provide safe housing, resistance to harsh environments and cost efficiency, supporting the electrification of heavy-duty vehicles.

They Trust Us

“FSW technology has the possibility that, when you weld, you don’t degrade the material as other process or other joining technologies. The main advantage that we see at Stirweld is the intercompability and the flexibility that the head provides us compared with a dedicated machine.”

Mario Alberto Solís Alvarez

R&D Innovation Engineer

Dive Deeper: Comprehensive FSW Battery Trays Resources

Are you curious to learn more about Friction Stir Welding and battery casings? We provide everything you need, including webinars, blog articles and practical guides.

Webinar – 45 min – Replay on demand

Stiffened panels welded by FSW

Discover how friction stir welding is transforming the assembly of stiffened panels for demanding applications. This session highlights the specific behaviour of 6xxx aluminium alloys and addresses the challenges of welding high-strength 2xxx and 7xxx grades. Gain valuable insights from leading industry experts and learn how to enhance performance, reduce costs and secure reliable results in your projects.

Blog articles – 5 min

Friction Stir Welding: a key technology for the future of e-mobility

Stiffened panels welded by FSW

White paper – 20 min

5 essential steps to master Friction Stir Welding

Master the fundamentals of friction stir welding with our practical guide. In just five essential steps, you’ll learn how to design, set up and optimise your FSW process to achieve strong, defect-free welds.

White paper – 20 min

Aluminium stiffened panels welded by FSW

Dive deeper into the manufacturing of stiffened aluminium panels with friction stir welding. This resource explains how FSW delivers durable, high-quality joints while helping you solve common assembly challenges with confidence.

Want to Cut Costs and Improve Battery Tray Assembly?

Friction Stir Welding ensures leak-tight, crash-resistant aluminium trays while reducing manufacturing costs. Contact our experts to optimise your assembly process.