STIRWELD FSW SERVICE

Friction Stir Welding Training

Train your team to become friction stir welding experts with Stirweld’s tailored FSW training – practical, flexible and ISO 25239 compliant.

Why Choose Stirweld for your Friction Stir Welding Training?

Advanced Technology Understanding

Gain deeper insights into Friction Stir Welding technology for innovative component design.

Master FSW Fundamental Concepts

Boost component development by enhancing design, optimizing welding parameters and increasing speeds.

FSW Proficiency

Enhance the capabilities of your team with state-of-the-art Friction Stir Welding technology.

Streamlined FSW Integration

Gain access to our comprehensive suite of commercial and technical documentation to facilitate the adoption of FSW at your facility.

How our Friction Stir welding Training Works?

At Stirweld, we are dedicated to providing top-notch, customizable training options designed to ensure your team excels in Friction Stir Welding (FSW). Our comprehensive training program is built with flexibility and personalization at its core, allowing us to tailor each session to meet your specific needs and objectives. We understand that every team has unique requirements and learning paces, which is why we offer a range of adaptable training solutions. Here’s an in-depth look at how our training process works:

Varied Modules

Total Customization

Flexible Formats

Classroom Training:

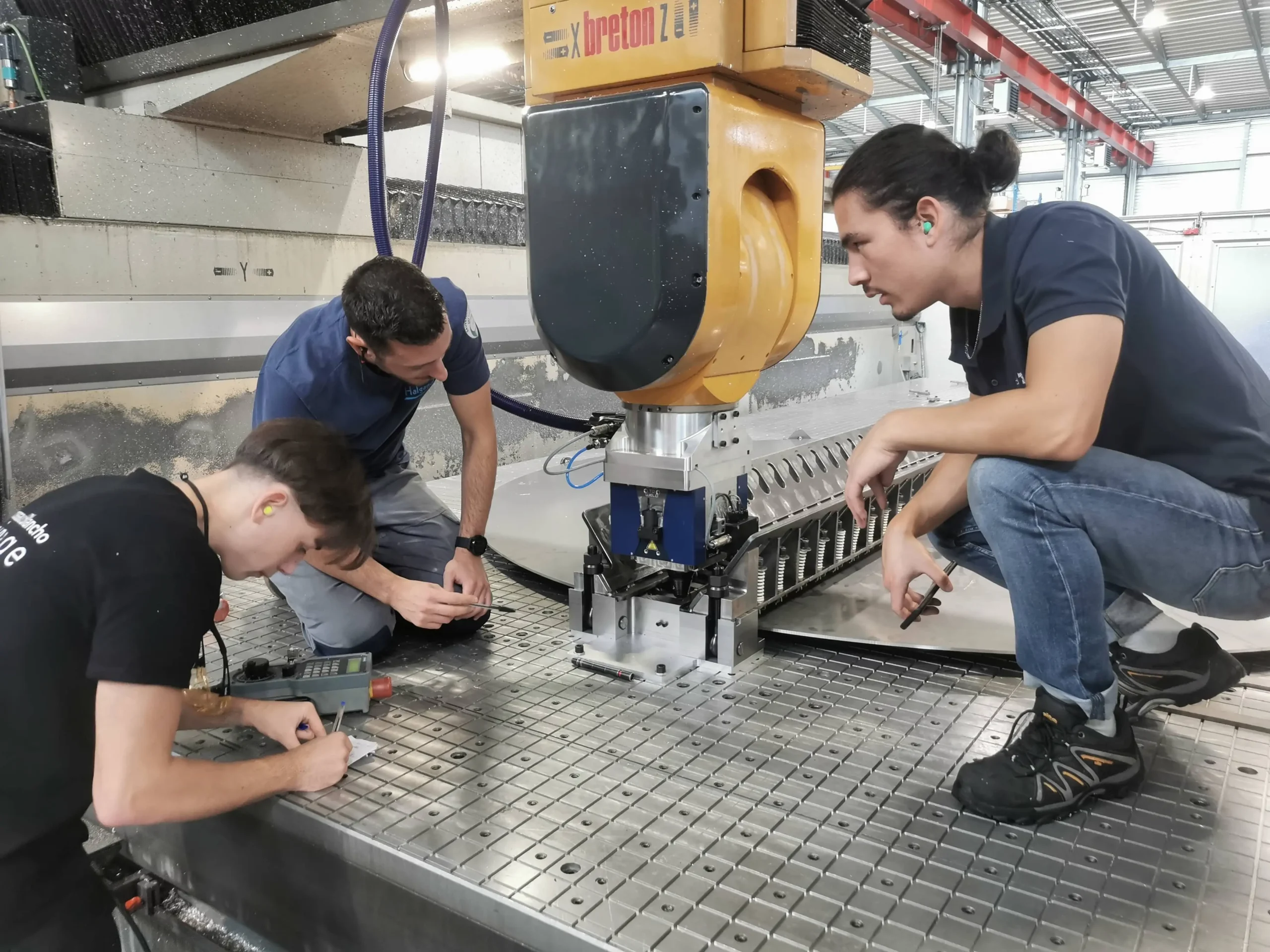

Workshop Training:

Master FSW with our Expert-Led Training

To ensure you and your team achieve proficiency in Friction Stir Welding, our FSW specialists will be dedicated to your learning over the course of the two-day program. They will be available to guide you through the training and to address all your queries as you progress through the course.

Detailed Training Modules

Explore our comprehensive range of training modules at Stirweld, each meticulously designed to enhance your team’s proficiency in Friction Stir Welding. Our modules cover both theoretical knowledge and practical skills, ensuring a well-rounded learning experience. Select the modules that best match your team’s requirements and take a step closer to mastering FSW. Below are detailed descriptions of our available modules:

Classroom Modules

Introduction to FSW

How to design your welded parts?

How to design a clamping system for FSW?

Workshop Modules

How to find welding parameters?

How to qualify your weld according to ISO 25239?

Focus on FSW for liquid cold plate

Our Bonus: all documents and support you need to implement Friction Stir Welding

Benefit from complimentary resources for successful FSW integration, including technical documents like design guidelines, part analysis, and WPS, as well as sales materials like market surveys, PowerPoint presentations, and e-training support.

FAQ – More About Our FSW Training

Find quick answers to your questions with our FAQ. This section covers a range of common inquiries, providing you with immediate solutions and detailed information.

Yes. Our modules are designed to support both new adopters and teams already operating FSW machinery. We help you refine parameters, optimize weld quality, and solve real production issues.

Absolutely. We offer multi-site and multi-team training plans, either online or on-site, to ensure consistent knowledge transfer across your organization.

While our training is not exam-based, progress is monitored through practical exercises and project-based application. You receive a final assessment based on team engagement and operational readiness.

Any sector working with aluminium components can benefit, especially automotive, aerospace, rail, and electronics — where FSW brings advantages in strength, precision, and defect reduction.

Yes. After training, our team remains available for remote or on-site support. We can assist with process adjustments, part qualification, or help integrate FSW into your production line.

Start Your Friction Stir Welding Training Journey

Transform your team into FSW experts with our expert-led Friction Stir Welding training. Contact us today to schedule a session tailored to your needs.