WHERE FSW TECHNOLOGY MAKES A DIFFERENCE

Friction Stir Welding in Shipbuilding

FSW technology revolutionizes naval construction with lightweight, high-quality and cost-effective components.

Unlocking Shipbuilding Potential with Advanced FSW Techniques

In the face of mounting environmental, economic and safety challenges in modern shipbuilding, Friction Stir Welding emerges as an eco-friendly, cost-effective and safer alternative, offering unparalleled quality and design flexibility. Its streamlined training and superior weld quality not only elevate shipyard efficiency but also champion regulatory and sustainability goals.

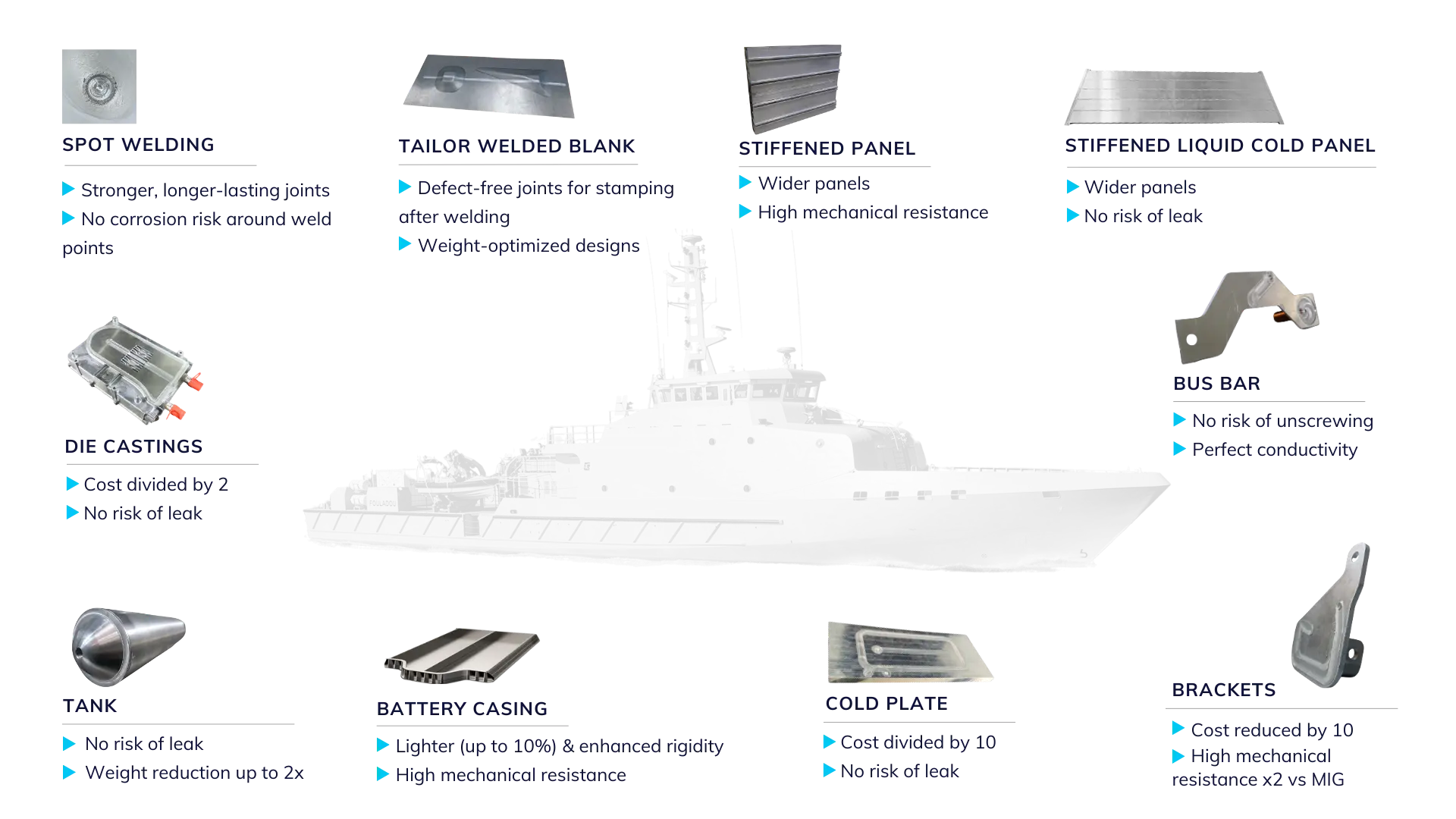

Exploring FSW Applications in the Shipbuilding Sector

Friction Stir Welding is pivotal for the maritime industry, providing unmatched quality, cost-efficiency and safety. Especially when it comes to welding critical components like ship floors or the cold plates of their electrical systems, FSW stands out as the technology of choice, both now and for the foreseeable future.

Stiffened panels

Primarily utilized in the robust hulls and decks of advanced maritime vessels, stiffened panels greatly benefit from FSW, a prevalent and trusted welding technique that significantly enhances these vital maritime structures.

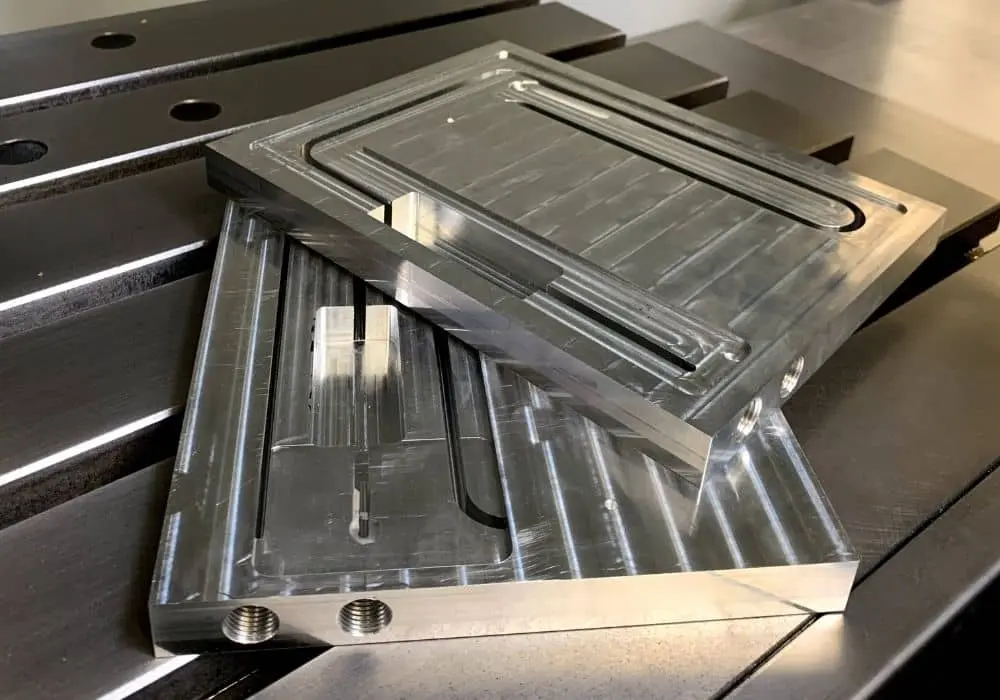

Cold plates

Essential for managing the thermal properties of electronic systems onboard modern vessels, liquid cold plates ensure the peak performance and prolonged durability of intricate maritime technologies.

Bus bars

Busbars welded by Friction Stir Welding offer reliable, corrosion-resistant electrical connections for marine environments, ideal for naval and commercial vessels alike.

Recommended FSW Equipment for Shipbuilding Applications

Our FSW machinery delivers unparalleled advantages in quality, cost-efficiency and environmental sustainability, perfectly aligning with the demanding expectations of the shipbuilding sector. Explore the specialized equipment our seasoned experts deem best-suited for your maritime projects

Standard FSW head for CNC

Designed for versatile use, this FSW head is effortlessly compatible with current 3, 4, or 5 axis machines. It instantly delivers precision in force control, live force tracking, effective tool temperature management and enhanced resistance to mechanical strains and tremors – all crucial for achieving top-notch FSW welding results.

FSW spindle for robot

Designed for heavy-duty robots, our FSW spindle transforms standard industrial robots into multifunctional devices. This robotic Friction Stir Welding approach integrates FSW technique, melding welding and machining tasks, enhanced with automatic tool-switching functions.

Dive Deeper: Comprehensive FSW Shipbuilding Applications Resources

Interested in delving deeper into FSW Shipbuilding Applications? We’ve curated a collection of insightful resources just for you, encompassing captivating webinars, enlightening articles and detailed whitepapers. Click below and immerse yourself in the wealth of information we’ve assembled for your benefit.

Webinar – 45 min – Replay on demand

Stiffened panels welded by FSW

Delve into cutting-edge methods of joining stiffened panels using friction stir welding. This session sheds light on the unique characteristics of 6xxx alloys and the complexities of the high strength 2xxx and 7xxx aluminum alloys. Benefit from the wisdom of industry leaders, making this essential viewing for both experienced practitioners and those eager to expand their understanding. Don’t miss out!

Blog articles – 5 min

Liquid cold plate: FSW assembly for more performance and savings

Resurgam Project: the major challenges for shipyards in friction stir welding on steel

White paper – 20 min

Overcoming cold plate manufacturing challenges

Uncover the capabilities of Friction Stir Welding in producing liquid cold plates in our illuminating white paper. Turn manufacturing challenges into opportunities by addressing pivotal issues with this guide.

White paper – 20 min

Aluminium stiffened panels welded by FSW

Dive deep into the flawless construction of stiffened aluminium panels with FSW in our concise white paper. Overcome assembly challenges with approaches that emphasize durability and robustness.

Set Sail with FSW Expertise

Enhance your shipbuilding projects with the unmatched advantages of Friction Stir Welding. Connect with our team today to revolutionize your maritime construction.