STIRWELD FSW EQUIPMENT

Automatic FSW head changer

Elevate your CNC machine to Industry 4.0: A hybrid system integrating machining and welding operations.

Enhance your Machine Versatility with our Automatic FSW Head Changer

Boost your productivity with our cutting-edge automatic FSW head changer. This revolutionary system allows for swift and smooth transitions between welding and machining, dramatically reducing downtime. Transform your setup into a versatile hybrid that excels at both FSW welding and precision milling operations. The key advantage lies in the significant time savings achieved by performing dual operations on one machine — fully automated and entirely hands-free.

Fully autonomous system

Experience the pinnacle of automation with our 100% automatic welding system.

Hybrid equipment

Merge welding and milling operations within a single CNC machine. Enhanced with comprehensive access to your entire carousel tool changer.

Optimized time cycles

Streamline your production with our time cycle optimization, designed for peak efficiency.

Maintenance-free

Enjoy the convenience of a no-maintenance solution to keep your operations running smoothly.

Accelerate welding speed

Achieve rapid production speeds of up to 3 m/min in your welding processes.

Universal solution

Our solution is adaptable ensuring seamless integration with your CNC machine.

Unlocking Friction Stir Welding x Milling: Principle of the Automatic FSW Head Changer

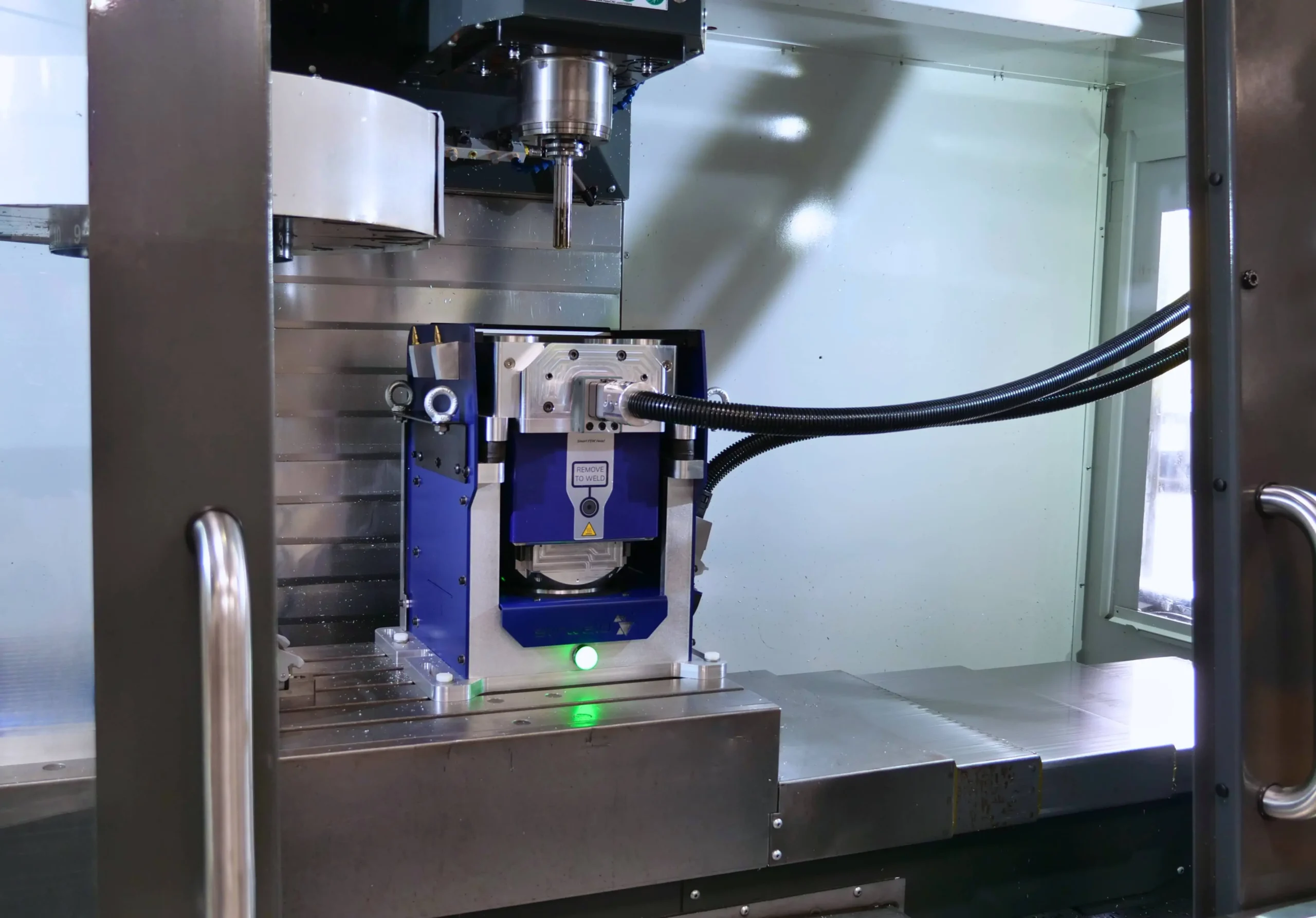

Safety Ensured with Protective Measures

The FSW head, securely positioned on the machine table, is safeguarded by a dynamic cover to ensure operator safety and component integrity.

Precision clamping by CNC spindle

Engage the FSW head with the CNC spindle, equipped with an automatic clamping device for seamless transition.

Friction Stir Welding Readiness

Your equipment is now ready for Friction Stir Welding, set to deliver exceptional welding performance.

Quality Completion and Delivery

Upon completion, your component meets the rigorous ISO 25239 quality standards, ready for dispatch to your client.

Machine Footprint of our Automatic FSW Head Changer

| Size | 300-mm long, (7.9 in), 300-mm wide (7.9 in) |

| Weight | 20 kg |

| Minimum spindle nose to table | 800 mm |

Frequently Asked Questions

Find quick answers to your questions with our FAQ. This section covers a range of common inquiries, providing you with immediate solutions and detailed information.

Yes, in most cases. Our system is designed to work with a wide range of vertical and 5-axis CNC machining centers. Not sure about your setup? Our technical team is here to check compatibility and guide you through it.

Not at all. The automatic head changer is a ready-to-use accessory. It integrates easily into your current machine, without heavy adjustments or downtime. Setup is quick — and you’re up and running in no time.

You can combine FSW with other machining operations such as milling, drilling or tapping—allowing full part processing in a single setup without manual intervention.

You save time at every step. No manual tool changes, no extra setups, no back-and-forth between workstations. Everything runs in one place, fully automated — and your cycle times get shorter, your process smoother.

Of course. We don’t just ship equipment — we support you all the way. From installation to first production runs, our FSW experts can assist remotely or on-site to make sure everything runs perfectly.

Customize Your CNC with FSW Automation

Elevate your production efficiency with our Automatic FSW Head Changer. Get in touch to tailor the perfect FSW automation solution for your CNC setup.